Multi Nozzle Desuperheaters

Get Price Quote

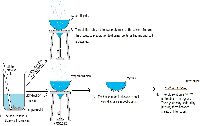

Desuperheatersare used to lower the temperature of superheated steam to the desired set point by injecting atomized water into the superheated steam flow. IndiTech has a wide range of desuperheaters that provide precise steam temperature control for variousapplications. High performance custom designed nozzles ensure that water is atomized into a fine mist at all process conditions. The complete range of IndiTech desuperheaters is easy to install and requires low maintenance. Variable Nozzle / Multi Nozzle Desuperheaters (Series 230) IndiTech Series 230 variable nozzle desuperheaters are best suited for applications involving high load fluctuations. They are designed to controlthe quantity of spray waterat the point of water injection, thereby eliminating the need of a separate water control valve. This is achieved by coupling the desuperheater with an actuator and subsequently varying the number of injection nozzles in operation.Nozzle opening is controlled through precise positioning of the desuperheater stem in response to feedback from a controller and downstream temperature sensor. Temperature reduction occurs as the fine mist ofwater rapidly vaporizes into the superheated steam. Features No external cooling water control valve required. Capable of maintaining steam temperature to saturation + 6°C. High performance spray nozzles that atomize water into a fine mist. Nozzles are stellited for water pressure drop more than 25 bar. Single piece forged body. Wide range of Kv / Cv values by using special nozzle combinations. All sealing joints (body-seat & body-nozzle holder) are stellited to provide leak tightness even after prolonged usage. Spray nozzles vacuum brazed to the body to prevent leakage, thereby avoiding disturbancesin the water swirl pattern and atomization. Approved under IBR (Indian Boiler Regulation Act).

continuous evaporator

Get Price Quote

Crystallization is a chemical solid-liquid separation technique, in which mass transfer of a solute from the liquid solution to a pure solid crystalline phase occurs, consisting of two major events, nucleation and crystal growth.

Best Deals from Evaporator

Forced Circulation Evaporators

Get Price Quote

Steam Coal Power Plant

100,000 Per Piece

Forced Circulation Evaporators

Get Price Quote

short tube evaporators

Get Price Quote

We are offering short tube evaporators.

Steam Desuperheaters

Get Price Quote

Steam Desuperheaters, pressure reducing cum desuperheating valve

evaporation plants

Get Price Quote

evaporation plants, ethanol plants, distillery plants, Dairy Plants

Nitrogen evaporator

Get Price Quote

Low Temperature Water Bath, Solid Phase Extraction Unit, Nitrogen Concentrator

Evaporators

Get Price Quote

Evaporators, Spray Dryers, fluidized spray dryers, Spin Flash Dryer

Evaporator

Get Price Quote

Evaporator, Sulphur Burner, Continuous Vacuum Pan, crystallizers

Multi Effect Evaporators

Get Price Quote

Multi Effect Evaporators, Food Processing Equipment, Fly Ash Disposal System