Steam Coal Power Plant

100,000 Per Piece

Multi Nozzle Desuperheaters

Get Price Quote

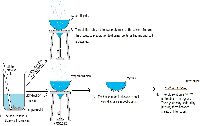

Desuperheatersare used to lower the temperature of superheated steam to the desired set point by injecting atomized water into the superheated steam flow. IndiTech has a wide range of desuperheaters that provide precise steam temperature control for variousapplications. High performance custom designed nozzles ensure that water is atomized into a fine mist at all process conditions. The complete range of IndiTech desuperheaters is easy to install and requires low maintenance. Variable Nozzle / Multi Nozzle Desuperheaters (Series 230) IndiTech Series 230 variable nozzle desuperheaters are best suited for applications involving high load fluctuations. They are designed to controlthe quantity of spray waterat the point of water injection, thereby eliminating the need of a separate water control valve. This is achieved by coupling the desuperheater with an actuator and subsequently varying the number of injection nozzles in operation.Nozzle opening is controlled through precise positioning of the desuperheater stem in response to feedback from a controller and downstream temperature sensor. Temperature reduction occurs as the fine mist ofwater rapidly vaporizes into the superheated steam. Features No external cooling water control valve required. Capable of maintaining steam temperature to saturation + 6°C. High performance spray nozzles that atomize water into a fine mist. Nozzles are stellited for water pressure drop more than 25 bar. Single piece forged body. Wide range of Kv / Cv values by using special nozzle combinations. All sealing joints (body-seat & body-nozzle holder) are stellited to provide leak tightness even after prolonged usage. Spray nozzles vacuum brazed to the body to prevent leakage, thereby avoiding disturbancesin the water swirl pattern and atomization. Approved under IBR (Indian Boiler Regulation Act).

Best Deals from Evaporator

Multiple Effect Evaporator

Get Price Quote

one Piece(s) (MOQ)

Fenix designs and manufactures efficient and elegant multiple effect evaporator (mee) at a low cost. Mee is an equipment system for efficiently using the heat from steam to evaporate water. In mee, liquor is boiled in a sequence of vessels, each held at a lower pressure than the previous vessel. Because the boiling point of water decreases with decreasing pressure, the vapour boiled off in one vessel can be used to heat the liquor in the next vessel and so on. Therefore only the first vessel at the highest pressure requires an external source of heat. In theory, evaporators may be built with very large number of stages. Evaporators with more than four stages are rarely practical except in systems where the liquor is the desired product. application: sodium hydroxide concentration of sugar solutions to very high solids content removal of water from soaps finishing concentration of some purees (apple, banana) removal of solvents from vegetable oils lignin solutions high concentration gelatin etc. warranty : process performance is guaranteed by us for 6 months post-commissioning.

evaporator plant

Get Price Quote

Our plants are tailor-made, taking into account the nature of the wastewater. Evaporators, although capital-intensive, are a necessary investment that ensures the proper treatment of industrial wastewater. We have a vast experience in treating the wastewater from a wide array of industries.

Evaporator

15,000,000 Per

1 Piece(s) (MOQ)

We are offering 5 nos. of condensers in SA516 Gr. 70 with seamless tubes and further all accessories and equipment fitted as per drawing and system. all ASME "U" stamping

continuous evaporator

Get Price Quote

Crystallization is a chemical solid-liquid separation technique, in which mass transfer of a solute from the liquid solution to a pure solid crystalline phase occurs, consisting of two major events, nucleation and crystal growth.

short tube evaporators

Get Price Quote

We are offering short tube evaporators.

Forced Circulation Evaporators

Get Price Quote

evaporation plants

Get Price Quote

evaporation plants, ethanol plants, distillery plants, fuel ethanol plant

Nitrogen evaporator

Get Price Quote

Nitrogen evaporator, Low Temperature Water Bath, Solid Phase Extraction Unit

Multi Effect Evaporators

Get Price Quote

Multi Effect Evaporators, Food Processing Equipment, Fly Ash Disposal System

Evaporator

Get Price Quote

Evaporator, Sulphur Burner, Continuous Vacuum Pan, crystallizers

Evaporators

Get Price Quote

Evaporators, Spray Dryers, fluidized spray dryers, Spin Flash Dryer

Evaporator

Get Price Quote

Evaporator, Kettles, Reactors, reaction tanks, Condensers

Steam Desuperheaters

Get Price Quote

Steam Desuperheaters, Control Valves