Milk Evaporation Plant

350,000 Per piece

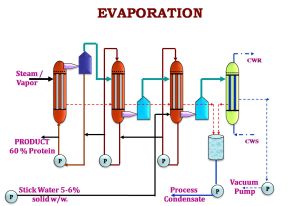

The manufacturing process for the evaporated milk involves precision standardization of the fat content and the dry solids contents. This is followed by heat treatment which partly destroys the microbes present in the milk. Checks are carried out on the coagulation stability of the milk before it is packaged in the sterilized cans. The product is then placed in an autoclave for sterilization. Finally the cans are cooled before storage.

Rotary Evaporator with Vacuum Pump and Chiller

Get Price Quote

1 Piece (MOQ)

Best Deals from Evaporator

Steam Bath Equipment

48,500 - 68,500 Per

1 Set (MOQ)

Instrumentation Evaporator

Get Price Quote

20 Piece (MOQ)

forced circulation evaporator

230,000 Per Piece

1 Piece (MOQ)

Single Coil Evaporation System

250,050 Per Units

1 Unit (MOQ)

Falling Film Evaporator

Get Price Quote

We design and manufacture Falling Film Evaporator for chemical plants.

Vacuum Evaporator

5,000,000 Per Piece

Open Pan Evaporimeters

73,000 - 76,500 Per one

1 Box (MOQ)

Multi Nozzle Desuperheaters

Get Price Quote

Desuperheatersare used to lower the temperature of superheated steam to the desired set point by injecting atomized water into the superheated steam flow. IndiTech has a wide range of desuperheaters that provide precise steam temperature control for variousapplications. High performance custom designed nozzles ensure that water is atomized into a fine mist at all process conditions. The complete range of IndiTech desuperheaters is easy to install and requires low maintenance. Variable Nozzle / Multi Nozzle Desuperheaters (Series 230) IndiTech Series 230 variable nozzle desuperheaters are best suited for applications involving high load fluctuations. They are designed to controlthe quantity of spray waterat the point of water injection, thereby eliminating the need of a separate water control valve. This is achieved by coupling the desuperheater with an actuator and subsequently varying the number of injection nozzles in operation.Nozzle opening is controlled through precise positioning of the desuperheater stem in response to feedback from a controller and downstream temperature sensor. Temperature reduction occurs as the fine mist ofwater rapidly vaporizes into the superheated steam. Features No external cooling water control valve required. Capable of maintaining steam temperature to saturation + 6°C. High performance spray nozzles that atomize water into a fine mist. Nozzles are stellited for water pressure drop more than 25 bar. Single piece forged body. Wide range of Kv / Cv values by using special nozzle combinations. All sealing joints (body-seat & body-nozzle holder) are stellited to provide leak tightness even after prolonged usage. Spray nozzles vacuum brazed to the body to prevent leakage, thereby avoiding disturbancesin the water swirl pattern and atomization. Approved under IBR (Indian Boiler Regulation Act).

Evaporator

Get Price Quote

Evaporators are critical to the processing of Fruits and Vegetables and serve a multitude of purposes in the Fruit and Vegetable processing industry. Falling and rising film evaporators are used to process dairy, prepare juice concentrates, and other sensitive products by operating rapidly without exposing such products to high temperatures that may otherwise affect their quality. Our range of Evaporators includes both Falling and Rising Film Evaporators, including the Five-Effect Falling Film Evaporators, Forced Circulation Evaporators, Two-Effect Forced Circulation Evaporators, and Double Effect Evaporators. We also offer Simple and Multi-effect Evaporators with the eventual application of Thermal Vapour Recompression (TVR) and Mechanical Vapour Recompression (MVR) for energy-saving.

Multi Effect Evaporators

Get Price Quote

Evaporator

Get Price Quote

Multiple Effect Evaporator Have Combination of Falling film and Forced circulation Evaporators to simplest and most effective approach to industrial wastewater minimization Reduce the effluent generation. Silent feature of Evaporation Technology:- 1. Reduce the cost of Production 2. Reduce the quantity of Effluent. 3. Minimum energy consumption i.e. Steam & Power 4. Less Manpower 5. Easy & stable operation

Vacuum Concentration System

Get Price Quote

We are supported by a team of quality auditors who make sure the product compliance in tune with the set quality standards. Owing to our immense expertise in this domain, we have carved a niche as a Supplier of Vacuum Concentration System in the market. For Processing of vegetable for frozen output to keep in cold storage.

Steam Desuperheaters

Get Price Quote

steam desuperheaters Desuperheater is a device which is sprays the high pressure water in the steam line thereby reducing the steam temperature to a point at or nearly at saturation temperature. An attemperator controls steam temperature while a desuperheater removes whatever superheat there is in steam.

Steam Power Plant

Get Price Quote

We are offering steam power plant.

Steam Cleaning Equipment

68,000 Per Piece

Evaporators

Get Price Quote

1 Piece(s) (MOQ)

We are offering evaporators. in evaporation, concentration of a product is accomplished by boiling out a solvent, generally water. Evaporation is widely used in processing foods and fruit juices, chemicals, pharmaceuticals, dairy products, beverages etc. our technology is supported by several test and development facilities where it is continually refined, improved and applied to new products. our portfolio of evaporators consist of : ● falling film evaporator ● forced circulation evaporator ● multiple effect evaporator ● agitated thin film evaporator ● short path distillation ● wiped film evaporator fenix advantages : continual interaction right from inquiry low capital cost high efficiency easy maintenance installation & comissioning services guarantee : process performance guaranteed for 6 months post-commissioning.

Patel Inhaler Vaporizer

100 - 150 Per

Premium quality products

Evaporator Unit

25,000 - 55,000 Per Nos

1 Piece (MOQ)

We manufacture premium quality Eavporator Units for Cold Room Applications