Taper Rollers

taper rollers are need at curve conveyors to make the product stable while moving along the curves. taper rollers are formed using pp bushes of length 50mm, plugged over each other to form taper portion. the taper portion have minimum dia available is 43mm and max dia is 106mm. There are various combinations possibles to get minimum dia and max dia. Please refer catalog. applications to carry automobile production casting & parts to carry carton boxes to carry plastic trays, crate to carry can, tin and other containers to carry wooden, metallic pallets

...more

Spiral Conveyor

Spiral Conveyors have two types: With Drive Without Drive Spiral Conveyors with drive are used to carry material from bottom to top or to control the speed of the product while coming from top to bottom. Spiral conveyors without drive and gravity spiral conveyors. These are generally used to bring carton boxes or generally any other material to bottom by gravity. Spiral conveyors are used to save space. Spiral conveyors are used in Milk And Milk product industries. Bakery industries. Courier and cargo industries. Automobile industries. Spiral Conveyors are made using Gravity Roller conveyors Slat chain conveyors Modular Belt conveyors

...more

Roller chain conveyor

These conveyors are used to carry material with speed and control. Suitable for size 38, 50, 60mm Variable load capacities Variable Speed available. These conveyors have wide applications industries lik Automobile Industries Food And Bakery Industries Plywood and wood industries Milk and allied industries

...more

powered rollers

Powered Rollers have various options to drive a rollers such as Sprocket, Timing Pulley, V Belt Pulley, Groove Rollers. Out of all this, sprockets are used most of the time to drive the rollers. Powered Rollers are used to carry heavy duty material as well as light duty material. The selection of powered rollers depends on the component to be carried as well as working conditions. Available in Dia. 38, 50 , 60, 80 Nylon Molded Bearing Housing Welded Sprocket Dust Cover in PP Power & Free Rollers also Available Applications To carry automobile production casting & parts To carry carton boxes To carry Plastic Trays, crate To carry Can, Tin and other containers To carry wooden, metallic pallets

...more

pallet conveyors

Pallet Conveyors are used to automatically transfer Standard Pallets, Slave Board, Boxes and Cartons having Flat Bottom Base from 50 to 1000 Kg load Capacity. Automatic cascading operations for handling the Pallets with Production and Movement cycles for the Fork Trucks or other handling equipment are easily integrated.

...more

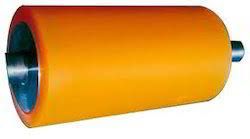

P u coated rollers

PU Coated rollers provide smooth surface to the component and assures damage free working of the component.

...more

Groove Rollers

Groove Rollers are used to carry lighter loads like carton boxes. The primary purpose of using Groove rollers is to avoid lubrication in the system. Sprockets driven powered rollers need lubrication for chain & sprocket, which may not be acceptable according to industry e.g. food & pharma. Groove section is created in the tube using forming process. PU cord is used to drive them. Available in Dia 38, 50 Groove Size 4mm Dia Steel as well as Stainless Steel Applications To carry automobile production casting & parts To carry carton boxes To carry Plastic Trays, crate To carry Can, Tin and other containers To carry wooden, metallic pallets

...more

gravity rollers

gravity rollers are used to carry material by gravity i.e. Weight of the component to be carried. Gravity conveyors are the easiest way to automatize your work in simple way and reduce manpower. Gravity roller selection depend on the dimensions, weight and material of the component. Their construction comprises a roller and shaft with molded bearing housing and dust cover. available in all sizes ranging from 25mm dia to 101mm dia. nylon molded bearing housing dust cover in pp. shafts in dia 8, 10,12,14,15,20,25applications to carry automobile production casting & parts to carry carton boxes to carry plastic trays, crate to carry can, tin and other containers to carry wooden, metallic pallets industries automobiles & allied industries food industries chemical industries pharma industries furniture milk & dairy

Size : 25mm dia to 101mm dia.

...more

gravity conveyors

Gravity conveyor moves the material by weight of the products. They are used to carry carton boxes, castings, plastic crates, automobile parts, assemblies, Drums.The weight of the component plays important part in design of the gravity roller conveyor. The width of the component + 50mm on each side equals to width of the gravity roller conveyor. The roller pitch is decided such a way that there are 3 rollers below the component every time to stabilize the product for even surfaces like carton box. For uneven surfaces, the rollers may be more.

...more

Gravity Conveyor

Gravity conveyor moves the material by weight of the products. They are used to carry carton boxes, castings, plastic crates, automobile parts, assemblies, Drums. Design of Gravity Conveyors: The weight of the component plays the important part in the design of the gravity roller conveyor. The width of the component + 50mm on each side equals the width of the gravity roller conveyor. The roller pitch is decided such a way that there are 3 rollers below the component every time to stabilize the product for even surfaces like carton box. For uneven surfaces, the rollers may be more. Gravity Roller Conveyors are available in various options depending on the application. Structure Aluminum Profile. Roller Material

...more

curve conveyors

We manufacture a customized range of Curve Conveyors. These Conveyors have an innovative design which is suitable for changing the direction of the material flow. Our Curve Conveyors are available in 90º as well as 180º curve. By utilizing high quality taper rollers & belts, these conveyors achieve the required curve. Made from rollers or belts, our Curve Conveyors utilize specially designed flatbeds. These quality Curve Conveyors can easily be integrated with normal conveyors for an enhanced functionality.

...more

Conveyor Power Roller

Owing to our sophisticated manufacturing facility, we have been able to offer a wide range of Conveyor Power Rollerthat is most commonly used forms of line restricted internal transport. Our adept professionals intricately manufacture this offered conveyor using quality assured components and the sophisticated technology. Apart from this, offeredConveyor Power Roller is stringently tested on various quality parameters to deliver a default free range at clients ‘end.

...more

Conveyor Components

A Industrial or belt Conveyor Roller consists of two or more pulleys, with a continuous loop of material - the conveyor belt - that rotates about them. One or both of the pulleys are powered, moving the belt and the material on the belt forward. The powered pulley is called the drive pulley while the unpowered pulley is called the idler. There are two main industrial classes of belt conveyors; those in general material handling such as those moving boxes along inside a factory and bulk material handling such as those used to transport industrial and agricultural materials, such as grain, coal, ores, etc. generally in outdoor locations. Generally companies providing general material handling type belt conveyors do not provide the conveyors for bulk material handling. In addition there are a number of commercial applications of belt conveyors such as those in grocery stores.

...more

Belt Conveyor

Flat Belt Conveyors are a simple in design and easy to maintenance. The flat belt has been evolved over the years with their applications. They have a lot of options according to applications. Such as – Food Grade Belt – where food items are in direct contact with the belt. PVC flat belt for general applications. Cleats to carry the material in an inclined direction. Sidewall with the cleat to carry small or powder items. Buckets to carry powder items. Rough Top Belt to generate friction. Depending on the application, users named the conveyors as inclined conveyors, printing conveyors, knife edge conveyor, warehouse conveyor and many more. The design of the flat belt conveyor can be also be done by various ways using direct Direct drive, central drive or indirect drive. Roller with Ball Bearing or Pillow Block Bearing. With Center Guide or Without Center Guide.

...more

Curved Conveyors

PVC Sleeve Roller

Magnetic Roller

Roller Track with Plastic Wheels

Be first to Rate

Rate ThisOpening Hours