valve bag packing machine

300,000 Per Piece

Milk Chilling Plant

1,000,000 Per Piece

1 Piece (MOQ)

Best Deals from Filling Line

Cylinders Cascade

Get Price Quote

We offer high quality Cylinders Cascade. A group of gas cylinders are interconnected by high pressure piping to form a single gas storage unit and are called a cascade. The cylinder cascade may contain from 6 to 600 gas cylinders.Widely used in various industries such as automotive, the primal benefit of the product is that it avoids individual handling of cylinders and adequate gas quantity resulting in better production planning and cost savings to the user.

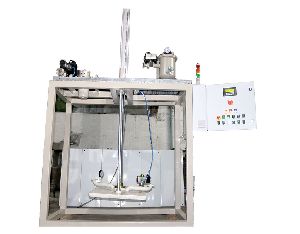

VACUUM OIL FILLING SYSTEM

Get Price Quote

The plant is specially designed for transformer oil filling in vacuum condition. It is able to evacuate and fill oil in transformer tank. Under vacuum condition, oil filling process can be automatically and manually operated With Computer, PLC control. Oil filling process programmed to start filling only after vacuum condition is reached, and to stop when each float switch in transformer has been reached. Oil filling line is connected to the Storage tank. Filling line will comprise of: Flow meter for recording flow rate Pneumatic valve for oil filling Flow meter controls the amount of oil to be filled. Connecting hose, filter and manual valve Filling hose LID up down arrangement by pneumatic cylinder. Oil filling process can be automatically and manually. When it is automatic, oil filling amount can be set via pneumatic valve. When it is up to setting value, valve will be closed automatically. All control of oil filling will be combined in main control cabinet.

valve bag filling machine

195,000 Per Piece

1 Piece (MOQ)

Milk Chilling Plant

Get Price Quote

In order to keep the products in safe condition during transit and handling, we meticulously pack them at our own packaging facility. Also, we make sure that the packaging material is sourced from the trusted vendors. Over the years, our company has a cemented its position in Pune(India) and is determined to become a trusted provider in other markets as well.Features : Quality assured Easy to operate Low maintenance 3000 LPD Approx Price : Rs 3.5 Lakh / Unit

Industrial Ro Water Treatment Plant

105,000 - 120,000 Per Piece

1 Piece (MOQ)

water source type - industrial effluent automation grade - semi-automatic treatment technique - ro capacity - 200-20000lph usage/application - recycle, drinking, electroplating, dialysis, boiler feed, food industry, bottling plant brand - bluemaarlin industry - pharmaceutical industry voltage - 220-380v frequency - 50 - 60hz type - mineral removal power source - electric material of construction - stainless steel, upvc, cpvc i deal in - new only country of origin - made in india in order to keep pace with the never-ending demands of the customers, our company is instrumental in offering industrial ro water treatment plant. reverse osmosis plants, ro plants, ro plant, ro system, ro machine, reverse osmosis system, reverse osmosis plant, ss ro, stainless steel ro, stainless steel reverse osmosis, automatic ss ro, automatic stainless steel ro, automatic stainless steel reverse osmosis, semi-automatic ro plant, semi-automatic ro, semi-automatic reverse osmosis, semi-automatic ss ro, semi-automatic ro machine, fully automatic ro, fully automatic reverse osmosis, automatic ro plant in ss, automatic ro plant in stainless steel.

Milk Chilling Plant

Get Price Quote

We are offering milk chiller that is available at industry leading rates with us. Milk chiller is used to improve the quality of the milk by collecting and cooling at a center before transporting the milk to the dairies. Made using high grade material, our milk chiller is highly efficient in functioning. Attributes :• Rugged• Construction Reliable• Performance Effectual• Performance Durable Capacity : From 200 litres to 10000 litres

Small sugar cone for chocolate filling

0 - 0 Per Piece

100000 Piece(s) (MOQ)

size-- 65 mm height and top daimeter 30 mm . using for chocolate filling . its a vety crispy and testy .

Demineralization Water Plants

600,000 Per Set

Principle of Operation : A Typical two-bed DM Plant consists of two MS Rubber lined Pressure vessels connected in series along with its internal fittings. The first unit consists of high capacity strongly acidic cation exchange resin, which converts positive ions of salt and replaces them with hydrogen ions to form respective acids, which are absorbed in next vessel by strongly basic anion exchange resin. The water obtained by this process shows conductivity less than 20 µ S / cm at 25 Deg C and total dissolved solids less than 10 ppm.Further high purity water can be achieved by Mixed Bed Deionisers, which are designed to produce high purity treated water. They can be used as polishing units after two bed DM Plant to obtain high purity water. Mixed Bed Deionisers are single column units, filled with strongly acidic cation and strongly basic anion exchange resins mixed together. There are four distinct stages in the operation of Deionisers Service Backwashing Regeneration Rinse/remix Service :In the Service cycle the water enters the vessel and passes through the Resin bed of the respective exchanger.Backwashing : After the resins are exhausted, the bed is backwashed. Backwashing is carried out by a uniform upward flow of water through the resin bed. The backwash step expands the resin bed releasing any entrapped particulate matter & removes the channeling in the resin column if occurred during the service cycle. Regeneration : When the ion exchange resins loose all the exchangeable ions, they require regeneration to restore them back to hydrogen or hydroxyl form depending upon whether they are cation or anion resins. To achieve this 4 - 5% concentrated solution of Hydrochloric acid is used for cation resin and a 4% - 5% concentrated solution of caustic soda for anion resin.Rinse : The final stage of regeneration is to rinse the resins of excess regenerant

Dm Water Plant

75,000 Per Unit

500 LPH Water Plant

100,000 Per plant

1 Piece (MOQ)

Juice Filling Machine

Get Price Quote

Owing to our strong tie-ups and vast industrial knowledge, we have been able to provide Juice Filling Machine to our credible customers nationwide as well as worldwide. Our Juice Filling Machine is comprehensibly in demand due to its high quality attributes and reliable performance. The product is equipped with latest technology that it makes a Canning line for filling the juice / pulp into cans. Customers can acquire Juice Filling Machine in varied specifications in terms of can size and speed, at nominal rates.

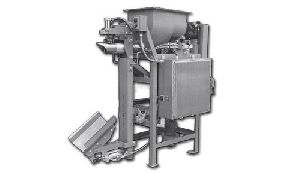

Positive Tubular Plate Filling Machines

Get Price Quote

The positive tubular plate filling mechanism comprises of an electromagnetic vibrator modified to prevent lead dust spillage. The plate filling cassette with aluminum spacers is designed such that the plates are filled effortlessly with minimum duration of vibrator usage. A hood around the vibrator contains the flying dust so that the dust collector can effectively pull it away from the operator. The dust collector with cartridge filter mechanism is so effective that all the flying dust pulled away from the operator to such an extent that the door of vibrator hood has to necessarily have an opening for air inlet. The fine 5 to 15 micron airborne lead oxide dust flying within the hood around the vibrator is sucked in to the dust collector by air currents developed by 0.5 to 0.7 m/s air rushing in to the hood through the front door. The dust laden air then passes through the filter cartridges where dust particles are collected on the filter element surface and 99.99% clean air is exhausted out to atmosphere. Due to dust collected on filter surface, the differential pressure across element starts to increase and during operation it remains steady between 100 to 150 mm WC indicating healthy operation of the unit. This is achieved by means of a reverse pulse jet mechanism controlled by a solenoid operated pulse valve and electronic timer. The frequency of cleaning is controlled automatically to maintain the optimum differential pressure across the filter elements resulting in 99.99% dust collection efficiency. Utility Requirement •Electric Power : 9 H.P. Connected Load – 3 Phase •Compressed Air : 6 kg/cm2 A Full View of The Filling Machine Complete With - Feeder hopper - Blender - Rotary valve - Vibrator with hood - Bottom bar fixing station & dust collector FAQ's We understand that there are certain queries that often asked and so we decided to bring forth to You, our clients and customers a common platform where all frequently asked questions and queries are answered to the best of our abilities. 1. What is the vibration mechanism ? The vibration is achieved by using a electromagnetic vibrator table. It has been observed that dry filling of fine lead dust in tubular bags is best achieved using such a mechanism instead of unbalanced motors or cam type vibrators or jolters. 2. Can the vibration be adjusted ? Yes – it can be adjusted using the controller provided in the control panel along with the Positive Tubular Plate Filling Machine. Additional settings can be done by adjusting the vibrator base bolts. Please refer to O & M manual for a detailed sketch and instructions pertaining to this adjustment. 3. Can the Positive Tubular Plate Filling Machine be used to fill 6 mm dia tubular bags ? Yes – the machine can fill plates having. 5.7 mm, 6.0 mm, 8.0 mm, 8.4 mm dia. tubular bags with correspondingly suitable spine thicknesses. 25 spines, 23 spines, 19 spines or 15 spines tubular plates – up to a max. width of approx. 190 mm. 95 mm, 105 mm … up to 540 mm ht. plates. 4. What is the duration required for filling? The actual time of vibration filling is 1½ mins. However the loading of grids fitted with tubular bags into the cassette, subsequent vibration and unloading of filled plates from the cassette usually needs 4 to 6 mins. per cycle. 5. What is the expected productivity per 8 hr. shift? The productivity shall depend on the speed with which the workmen load grids into the cassette and unload filled plates from the cassette. The min. productivity per eight hour shift shall be in the range of 600 to 800 nos. depending on plate size. 6. How exactly does the dust collector work? The dust collector works very effectively pulling all dust away from the operators. The dust gets collected on the surface of the filter cartridges and clean air is exhausted out to the atmosphere. The blower fan remains ‘ON’ throughout creating the exhaust draft for the fine lead dust. The dust collected on the surface of the filter cartridges is dislodged by means of reverse pulse jet of air at regular periodic intervals which is controlled by a timer using diaphragm valve. The dust is collected in a container at the bottom of the hopper. This container should be emptied periodically. 7. What exactly does the differential pressure gauge of dust collector indicate? The differential pressure gauge indicates the pressure drop across the filter cartridge elements. This differential pressure is an indicator of the condition of the filter elements. More the differential pressure – more the dust accumulated on the filter cartridge. This pressure differential must be normally between 100 mm w.c. and 150 mm w.c.. The gauge has a full scale display up to 250 mm w.c. In case the indication exceeds 150 mm w.c. and remains there for long time you must check whether the exhaust flap is fully open. If yes, please close the flap up to 50% or more and check the gauge. In case the gauge indication is not as per recommendations and the suction of dust collector is not efficient / as required – remove the filter cartridges, clean it using compressed air and fit it in place again. You can also try OFFLINE pulsing i.e. keep the blower ON for about 30 minutes or so after the production of filling has been stopped for the day.

juice processing plant

Get Price Quote

Fruit juices are made from fruit pulpconcentrate artificial sugar may or may not be added to the juice extracted. The sugar syrup is prepared first in jacketed mixing tank and then it is mixed with fruit pulp, water along with other ingredients like flavor, color, preservatives etc. In the other mixing tank. This mixture is pasteurized to remove any microbial growth from it and later on homogenized to prepare a uniform blend of juice. complete sets of fruit juice beverages and soft drinks production line: 1. Sugar syrup preparation tank 2. Fruit pulp storage tank 3. Filter press 4. Blending 5. Homogenization 6. Standardization 7. Pasteurization 8. Filling line: - automatic bottle filling line with rinsing filling & cap sealing machine in addition to the above machine, we can also offer a bottle blow molding plant which will make bottles for you from pet preform per your desired shape and size.

industrial ro mineral water plant

125,000 Per Piece

We offer industrial ro mineral water plant. Industrial ro plants configured for achieving optimum recovery of water.adjustable valve provision for adjusting waste and recycle flow of water.offering easy and quick installation.500 lph. Capacity.spun filter 20''.membranes housing 40*80.

Fruit Juice Plant

Get Price Quote

As we follow the automated warehousing system, we ensure safe assembling as well as storage of the entire lot. Moreover, the system is well managed by our team of experts. We are the most demanding entity when it comes to Fruit Juice Plant! We Offers Multiple Fruit Processing Plant For Production Of Juices/pulps : Apple, Pineapple Mango Tomato Papaya Guava Berry Grapes Oranges Lemon

Automatic Washing Machine

21,000 Per Piece

We are the main supplier of this product.

Compact Water Treatment Plants

Get Price Quote

We offer a wide gamut of Sewage Treatment Plant that is designed to receive the waste from domestic, commercial and industrial sources and to remove materials that damage water quality and compromise public health and safety when discharged into water receiving systems.

Knitting Needle Filling Machine

250,000 Per Units

food depositor filling machine

Get Price Quote

We are offering Depositor, used to form shapes of cookies and deposit cup cakes, bar cakes. available in 3 models with multiple nozzles and programmable panel. products deposited on trays.

Powder Packing Machine

Get Price Quote

Applications: Powders (Free and Non-free flowing), such as Spices, Soup Mixes, Detergents, Yeast, Desserts, Pharmaceutical and Agricultural Powders, Flour (Atta), Cocoa Powder, Drinking Chocolate, Coffee, Sugar. Filling Range: 50 gms to 2500 gms. Depending upon bulk density of products. General Information A vertical form, fill and seal machine for producing centre sealed pouches handling all types of free flowing/non-free flowing powders. The model AF-1000 handles a single reel film stock. Max. reel dia. is 530 mm on 76 mm core. The machine has the facility to be provided with a variety of filling heads. Draw down of the film is through draw down belts controlled through a Variable Frequency Drive. The length of the bag is controlled by print registration system which is PLC based. For unprinted film, the bag length can be adjusted from the single touch key pad provided on the front panel. Special Features • PLC controls with HMI • Draw-Dawn Belts Driven by Variable Frequency Drive. • Adjustable draw down belts • PC uplink facility (optional) • Password protection for settings (optional) • Facility of production count. Attachments: Infeed conveyor. Outfeed conveyor, Batch coding machine, Static charge removal system, N2 Flushing, Air removal system, Batch cutting attachment, Different sealing patterns, Different Pouch Cutting Attachments.

Sewage Treatment Plant

Get Price Quote

Using Our Cutting Edge Technology, We are Able to Provide Brilliant Quality Sewage Water Treatment Plant. Our Industrial ,Sewage Treatment Plant is Precisely Designed to Eradicate Sewage Problems such as Contamination of Water, Choked Water Etc. We are Counted among the Supreme Sewage Treatment Plant Manufacturers, Based in India.

gravity filling machines

Get Price Quote

The Gravity Filling Machines are designed for filling any free flowing product into glass or plastic containers – from 150ml to 5 liters.The Gravity Filler is ideal for filling thin liquids with consistent viscosity. Volumetric time gravity filling method produces repeatable and accurate fill volumes. The frame is made in stainless steel together with stainless steel worktop and product tank. It also features user friendly PLC controls and touch screen HMI panel. The empty containers are placed directly on to the filling nozzle and lowered back down on to the bottle bar. They are then filled automatically and to a preset level then can be placed onto a table top ready for capping. This easy operation ensures quick and constant production. Many more features and options are available for even more versatility and customization. Gravity Fillers are utilized by the food and beverage, cleaning and specialty chemical, pharmaceutical, cosmetic and personal care industries for various filling projects. The Automatic Gravity Filler can be built to suit a wide variety of applications including sanitary, hazardous, flammable, and corrosive products and environments

semi automatic weigh filler machine

Get Price Quote

Head Options : 1 Head, 2 Head, 3 Head, 4 Head, 6 Head. Packaging material Any ready pouches Jar, Bags, Containers etc. Power Requirement 220V AC 1 Phase, 50 Hz. Compressed Air Required 5 kgfsq.cm.

Base Cap Bracket Welding Machine

Get Price Quote

grease filling machine

158,000 Per Unit

Automatic Filling Machine

200,000 - 250,000 Per Piece

Pneumatic Air Headers

Get Price Quote

We have been emerged as a prominent manufacturer and suppliers of Pneumatic Air Headers which are perfectly manufactured by experienced manpower. Air headers are ideal for replacing valve assemblies that are generally operated from one source.

Pet Blowing Machine

Get Price Quote

Pet blowing machine ...automatic as well as semiautomatic we can supply...we are dealing in pet as well as pp,hdpe raw material