Milk Chilling Plant

1,000,000 Per Piece

1 Piece (MOQ)

Water Softening Plant

25,000 Per Piece

Best Deals from Filling Machine

Fruit Juice Processing Plant

Get Price Quote

We have with us extensive experience in successfully designing the fruit juice processing plant. The complete line of fruit juice processing plants are offered meet the processing needs of fruits like apple, mango , orange pineapple, papaya, guava, berry, grapes, lemon are made available in various operating capacities . The type of processing plant varies based on the product ,juice like apple,grape, lemon etc can be proceed with the plate of heat exchanger and viscous product like mango, guava, etc needs to be proceed with corrugated tubular heat exchanger 1. all equipment made up of ss 304. 2. low operating cost. 3. easy to handled. 4. we provide technical guidance.

DM Plant

Get Price Quote

A Typical two-bed DM Plant consists of two MS Rubber lined Pressure vessels connected in series along with its internal fittings. The first unit consists of high capacity strongly acidic cation exchange resin, which converts positive ions of salt and replaces them with hydrogen ions to form respective acids, which are absorbed in next vessel by strongly basic anion exchange resin. The water obtained by this process shows conductivity less than 20 µ S cm at 25 Deg C and total dissolved solids less than 10 ppm.Further high purity water can be achieved by Mixed Bed Deionisers, which are designed to produce high purity treated water. They can be used as polishing units after two bed DM Plant to obtain high purity water. Mixed Bed Deionisers are single column units, filled with strongly acidic cation and strongly basic anion exchange resins mixed together.

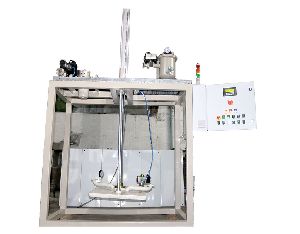

VACUUM OIL FILLING SYSTEM

Get Price Quote

The plant is specially designed for transformer oil filling in vacuum condition. It is able to evacuate and fill oil in transformer tank. Under vacuum condition, oil filling process can be automatically and manually operated With Computer, PLC control. Oil filling process programmed to start filling only after vacuum condition is reached, and to stop when each float switch in transformer has been reached. Oil filling line is connected to the Storage tank. Filling line will comprise of: Flow meter for recording flow rate Pneumatic valve for oil filling Flow meter controls the amount of oil to be filled. Connecting hose, filter and manual valve Filling hose LID up down arrangement by pneumatic cylinder. Oil filling process can be automatically and manually. When it is automatic, oil filling amount can be set via pneumatic valve. When it is up to setting value, valve will be closed automatically. All control of oil filling will be combined in main control cabinet.

Milk Chilling Plant

Get Price Quote

In order to keep the products in safe condition during transit and handling, we meticulously pack them at our own packaging facility. Also, we make sure that the packaging material is sourced from the trusted vendors. Over the years, our company has a cemented its position in Pune(India) and is determined to become a trusted provider in other markets as well.Features : Quality assured Easy to operate Low maintenance 3000 LPD Approx Price : Rs 3.5 Lakh / Unit

Automatic Washing Machine

21,000 Per Piece

We are the main supplier of this product.

Juice Filling Machine

Get Price Quote

Owing to our strong tie-ups and vast industrial knowledge, we have been able to provide Juice Filling Machine to our credible customers nationwide as well as worldwide. Our Juice Filling Machine is comprehensibly in demand due to its high quality attributes and reliable performance. The product is equipped with latest technology that it makes a Canning line for filling the juice / pulp into cans. Customers can acquire Juice Filling Machine in varied specifications in terms of can size and speed, at nominal rates.

Fruit Juice Plant

Get Price Quote

As we follow the automated warehousing system, we ensure safe assembling as well as storage of the entire lot. Moreover, the system is well managed by our team of experts. We are the most demanding entity when it comes to Fruit Juice Plant! We Offers Multiple Fruit Processing Plant For Production Of Juices/pulps : Apple, Pineapple Mango Tomato Papaya Guava Berry Grapes Oranges Lemon

Industrial Ro Water Treatment Plant

105,000 - 120,000 Per Piece

1 Piece (MOQ)

water source type - industrial effluent automation grade - semi-automatic treatment technique - ro capacity - 200-20000lph usage/application - recycle, drinking, electroplating, dialysis, boiler feed, food industry, bottling plant brand - bluemaarlin industry - pharmaceutical industry voltage - 220-380v frequency - 50 - 60hz type - mineral removal power source - electric material of construction - stainless steel, upvc, cpvc i deal in - new only country of origin - made in india in order to keep pace with the never-ending demands of the customers, our company is instrumental in offering industrial ro water treatment plant. reverse osmosis plants, ro plants, ro plant, ro system, ro machine, reverse osmosis system, reverse osmosis plant, ss ro, stainless steel ro, stainless steel reverse osmosis, automatic ss ro, automatic stainless steel ro, automatic stainless steel reverse osmosis, semi-automatic ro plant, semi-automatic ro, semi-automatic reverse osmosis, semi-automatic ss ro, semi-automatic ro machine, fully automatic ro, fully automatic reverse osmosis, automatic ro plant in ss, automatic ro plant in stainless steel.

Positive Tubular Plate Filling Machines

Get Price Quote

The positive tubular plate filling mechanism comprises of an electromagnetic vibrator modified to prevent lead dust spillage. The plate filling cassette with aluminum spacers is designed such that the plates are filled effortlessly with minimum duration of vibrator usage. A hood around the vibrator contains the flying dust so that the dust collector can effectively pull it away from the operator. The dust collector with cartridge filter mechanism is so effective that all the flying dust pulled away from the operator to such an extent that the door of vibrator hood has to necessarily have an opening for air inlet. The fine 5 to 15 micron airborne lead oxide dust flying within the hood around the vibrator is sucked in to the dust collector by air currents developed by 0.5 to 0.7 m/s air rushing in to the hood through the front door. The dust laden air then passes through the filter cartridges where dust particles are collected on the filter element surface and 99.99% clean air is exhausted out to atmosphere. Due to dust collected on filter surface, the differential pressure across element starts to increase and during operation it remains steady between 100 to 150 mm WC indicating healthy operation of the unit. This is achieved by means of a reverse pulse jet mechanism controlled by a solenoid operated pulse valve and electronic timer. The frequency of cleaning is controlled automatically to maintain the optimum differential pressure across the filter elements resulting in 99.99% dust collection efficiency. Utility Requirement •Electric Power : 9 H.P. Connected Load – 3 Phase •Compressed Air : 6 kg/cm2 A Full View of The Filling Machine Complete With - Feeder hopper - Blender - Rotary valve - Vibrator with hood - Bottom bar fixing station & dust collector FAQ's We understand that there are certain queries that often asked and so we decided to bring forth to You, our clients and customers a common platform where all frequently asked questions and queries are answered to the best of our abilities. 1. What is the vibration mechanism ? The vibration is achieved by using a electromagnetic vibrator table. It has been observed that dry filling of fine lead dust in tubular bags is best achieved using such a mechanism instead of unbalanced motors or cam type vibrators or jolters. 2. Can the vibration be adjusted ? Yes – it can be adjusted using the controller provided in the control panel along with the Positive Tubular Plate Filling Machine. Additional settings can be done by adjusting the vibrator base bolts. Please refer to O & M manual for a detailed sketch and instructions pertaining to this adjustment. 3. Can the Positive Tubular Plate Filling Machine be used to fill 6 mm dia tubular bags ? Yes – the machine can fill plates having. 5.7 mm, 6.0 mm, 8.0 mm, 8.4 mm dia. tubular bags with correspondingly suitable spine thicknesses. 25 spines, 23 spines, 19 spines or 15 spines tubular plates – up to a max. width of approx. 190 mm. 95 mm, 105 mm … up to 540 mm ht. plates. 4. What is the duration required for filling? The actual time of vibration filling is 1½ mins. However the loading of grids fitted with tubular bags into the cassette, subsequent vibration and unloading of filled plates from the cassette usually needs 4 to 6 mins. per cycle. 5. What is the expected productivity per 8 hr. shift? The productivity shall depend on the speed with which the workmen load grids into the cassette and unload filled plates from the cassette. The min. productivity per eight hour shift shall be in the range of 600 to 800 nos. depending on plate size. 6. How exactly does the dust collector work? The dust collector works very effectively pulling all dust away from the operators. The dust gets collected on the surface of the filter cartridges and clean air is exhausted out to the atmosphere. The blower fan remains ‘ON’ throughout creating the exhaust draft for the fine lead dust. The dust collected on the surface of the filter cartridges is dislodged by means of reverse pulse jet of air at regular periodic intervals which is controlled by a timer using diaphragm valve. The dust is collected in a container at the bottom of the hopper. This container should be emptied periodically. 7. What exactly does the differential pressure gauge of dust collector indicate? The differential pressure gauge indicates the pressure drop across the filter cartridge elements. This differential pressure is an indicator of the condition of the filter elements. More the differential pressure – more the dust accumulated on the filter cartridge. This pressure differential must be normally between 100 mm w.c. and 150 mm w.c.. The gauge has a full scale display up to 250 mm w.c. In case the indication exceeds 150 mm w.c. and remains there for long time you must check whether the exhaust flap is fully open. If yes, please close the flap up to 50% or more and check the gauge. In case the gauge indication is not as per recommendations and the suction of dust collector is not efficient / as required – remove the filter cartridges, clean it using compressed air and fit it in place again. You can also try OFFLINE pulsing i.e. keep the blower ON for about 30 minutes or so after the production of filling has been stopped for the day.

Milk Chilling Plant

Get Price Quote

We are offering milk chiller that is available at industry leading rates with us. Milk chiller is used to improve the quality of the milk by collecting and cooling at a center before transporting the milk to the dairies. Made using high grade material, our milk chiller is highly efficient in functioning. Attributes :• Rugged• Construction Reliable• Performance Effectual• Performance Durable Capacity : From 200 litres to 10000 litres

Demineralisation Water Treatment Plant

Get Price Quote

Our range of Demineralisation Water Treatment Plant with MB are used in many type of industries. These demineralized water systems are designed in a way that removes the dissolved solids from the raw water. The Demineralization Plant comprises strong acid cation and strong base anion unit that purifies water passing through it. This process offers water with less than 15 microScm conduction and very less total dissolved solids. The entire range is available in various specifications and can be customized as per clients' specifications. Our demineralization plant performs efficiently in purifying and removing varieties of dissolved impurities from water. Equipped with advanced filters.

aerosol filling machine

Get Price Quote

Features:- Line includes Automatic Aerosol liquid filling, Crimping & Gassing. Valve insertion will be in manual, Facility of batch coding at side wall and bottom surface. Filling Range 25 ml to 300 ml .without any change parts. Same machine can be used for smaller volumes 10 ml to 100 ml with suitable change parts. Diving nozzle mechanism avoids foaming & spillage. Positive shut-off Nozzle helps in keeping the filling area clean. Available as standalone Machine, and also with crimping & gassing. ApplicationsThis line can be used to fill Aerosols, Paint sprays, Deodrants, saint sprays, body odours, Automobile sprays, WD-40 sprays etc,.

Juice Filling Machine

650,000 - 700,000 Per Piece

Industrial Ro Plant

Get Price Quote

Our Industrial Ro Plant is Specially Designed to Purify Water with High Efficiency. Our Industrial Reverse Osmosis System is Available in Various Ranges from 400 Lph to 3000 Lph. Our Reverse Osmosis Purification System is Easy to Maintain, Operate and Use. We are Counted among the Predominant Reverse Osmosis Purification System Manufacturers, Based in India. features simple to Operate, Easy to Maintain, Automatic Operation, Compact, Adequate Safety Interlocks, Reject Recycle Loops for Higher Recovery.

semi automatic weigh filler machine

Get Price Quote

Head Options : 1 Head, 2 Head, 3 Head, 4 Head, 6 Head. Packaging material Any ready pouches Jar, Bags, Containers etc. Power Requirement 220V AC 1 Phase, 50 Hz. Compressed Air Required 5 kgfsq.cm.

Oil Filling Machine

Get Price Quote

Multi Head Weigh Filler

Get Price Quote

food depositor filling machine

Get Price Quote

We are offering Depositor, used to form shapes of cookies and deposit cup cakes, bar cakes. available in 3 models with multiple nozzles and programmable panel. products deposited on trays.

Oil Filling Machine

Get Price Quote

JAL, Oil filling in shock absorber tubes and front fork assembly a filling accuracy of +- 0.5 ml for precise control with digital flow meter and pneumatic piston pump. Two filling station with on line conveyor based system. Features Manual, Timer, or Cycle Operation Modes Foot Pedal or Finger Switch Controlled Programmable Timer 0.01 – 99.99 seconds Suck-Back feature ensures no dripping

Bagging Machine Automations

Get Price Quote

We are offering Bagging Machine Automations. we takes up project for automatic the bagging machines. the process of manually bag placing and feeding the machine to the stitching units is automated by means of bag placer and autostitching units.

Automatic Filling Machine

200,000 - 250,000 Per Piece

Knitting Needle Filling Machine

250,000 Per Units

Hot Juice Filling Line

Get Price Quote

Resin Filling Machine

Get Price Quote

Twin's specialized systems for infusion of two component resin used in fiber matting process in manufacturing of windmill rotor blades. Get accurate ratio control throughout the infusion process while ensuring the best efficiency.

Water Softening Plant

45,000 Per Piece

01 Piece (MOQ)

Pet Blowing Machine

Get Price Quote

Pet blowing machine, Compact modular box frame, powder coated and well balanced structure, to reduce vibrations and distortions. The integrated system of PET stretch-blow moulding machine featured by SBR Machines, combines latest technologies along with unmatched quality to offer world class products. Our machine stands out for

Water Treatment Plant

Get Price Quote

-RO Plant -Ultra Filteration -Nano Filtration -Sand Filter -Activaated Carbon Filter -Iron Removal Filter -ION Exchange plant like-Softener, D.M. Plant, Dealkalizer -Dual Media filter.

plastic cap moulding machine

Get Price Quote

We are leading manufacturer and supplier of Cap Moudling Machine in ahmedabad, Gujarat, India. We have large range of Cap Moulding Machine.