SACK SWEEPER

Get Price Quote

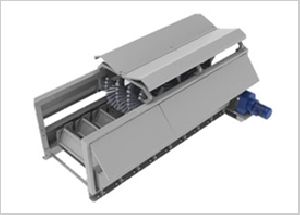

Cleans the sack from bottom, sides and top Installed at the sack discharge end of Rotary Packer. Recovers the spillage and dust on the sack Keeps the packing area clean Improves the working environment Uses the draught of the packer No extra air used Single drive in the form of geared motor The bed of the sack sweeper is made of powered rollers. The hollow rollers are fitted with brush that rotates in the opposite direction to make the brushing effective. The top brushes are also powered and fitted with bristles that can clean the sacks from top and sides. The level of the top brush can be adjusted to compensate the reduced length of the brush when it wears off. Safety covers are fitted on both sides. These covers are loaded with gas springs for ease of opening and closing. The drive is in the form of cascaded chains and sprockets – powered by a geared motor. The drive can be located on either side of the sack sweeper. The rpm of the geared motor can be chosen to suit the packer throughput. Top bonnet can be opened and closed with ease with the help of gas springs. Emergency stop push buttons are provided in all the four corners of the sweeper module

SACK SWEEPER

Get Price Quote

Cleans the sack from bottom, sides and top Installed at the sack discharge end of Rotary Packer. Recovers the spillage and dust on the sack Keeps the packing area clean Improves the working environment Uses the draught of the packer No extra air used Single drive in the form of geared motor The main module has pedestals at inlet and outlet which can be adjusted to match with the upstream and downstream of the equipment. This ensures smooth movement of the bags during transfers. The bed of the sack sweeper is made of powered rollers. The hollow rollers are fitted with brush that rotates in the opposite direction to make the brushing effective. The top brushes are also powered and fitted with bristles that can clean the sacks from top and sides. The level of the top brush can be adjusted to compensate the reduced length of the brush when it wears off. Safety covers are fitted on both sides. These covers are loaded with gas springs for ease of opening and closing. The drive is in the form of cascaded chains and sprockets – powered by a geared motor. The drive can be located on either side of the sack sweeper. The rpm of the geared motor can be chosen to suit the packer throughput. Top bonnet can be opened and closed with ease with the help of gas springs. Emergency stop push buttons are provided in all the four corners of the sweeper module

Best Deals from Floor Cleaning Machine

Floor Boring Machine

5,000,000 Per UNIT

Floor Cleaner

Get Price Quote

we are offering floor cleaner with power of gomutra and neem is used to remove allergens and to make environment sanitary.

Fume Scrubbing System

700,000 Per unit

Road Cleaning Machine

Get Price Quote

It can gathers the waste from the corners, the tubular main brush under the machine sweeps up the debris from the floor and packs it into the container located at the front.

Walk Behind Floor Sweeper

45,000 Per Piece

Floor Cleaning Machines

Get Price Quote

Floor Cleaning Machines, Floor Cleaning Chemicals

Floor Scrubbing Machine

Get Price Quote

Floor Scrubbing Machine

Floor Cleaner

Get Price Quote

diwali gift set, Herbal Shampoo, Agarbatti Stick, Snan Utane, Gomay Tel

Fume Scrubbing System

Get Price Quote

Fume Scrubbing System, dust extraction

Floor Cleaner

Get Price Quote

Detergent Liquid Utensil, Detergent Powder, Detergent Powder Utensil

vacuum cleaning machines

Get Price Quote

vacuum cleaning machines, Lcd Tv, Almirah, Bed, Chair, Wooden Table