Water Treatment Plants

We at Fluid Systems are engaged in manufacturing and supplying a wide range of Water Treatment Plants, Sewage Treatment Plants, Effluent Treatment Plants and Packaged Water Treatment Plants. Apart from these we also offer package sewage treatment, combined sewage cum food waste treatment plants and combined sewage cum effluent treatment plants. We also offer effective turnkey solutions for these plants to our clients. Our entire range of plants and services are widely demanded in pharmaceutical industry, chemical manufacturing industry and food processing industry to name a few.Our tremendous success in this highly competitive sector is solely credited to the resources owned by us and our manpower being one of them. We have a team of professionals who have immense expertise in handling the sophisticated manufacturing process and later in providing effectual turnkey services to our clients. We have an excellent infrastructure to design, engineer, manufacture, carry out erection and commissioning the complete range of water treatment plant and systems to suit various requirements. The Wide Range of Water Treatment Plants supplied by us in India: Raw Water Treatment Plants Drinking Water Treatment Plants Municipal Water Treatment Plants Packaged Drinking Water Treatment Plants Mineral Water Treatment Plants Spring Water Treatment Plants Sea Water Treatment Plants Turnkey Water Treatment Plants Process Water Treatment Plants Sewage Water Treatment Plants Effluent Water Treatment Plants Waste Water Treatment Plants Municipal Waste Water Treatment Plants Fully Automatic Water Treatment Plants

...more

WATER SOFTENERS PLANT

Fluid Systems is an export oriented manufacturing company of Water Softeners in India. Fluid Systems is a leading brand in the field of Water Softeners. This water softening Plants are based on the proven ion exchange process. The Water Softeners are simple in operation, highly efficient and compact units designed to produce soft water efficiently and economically. The Water Softeners are available in different sizes and materials, manually operated or fully Automatic, & ready to install. The Water Softening Plants are available as standard models or custom built versions for specific needs. Water Softening Plants -Operating Principle The Water Softeners are charged with a high capacity polystyrene bead cation exchange resin in sodium form. When hard water passes through this resin column, the hardness forming calcium and magnesium salts are replaced with sodium salts which do not posses any hardness properties. This softening process is continuous until the material is exhausted of sodium salts when it is regenerated with a solution of common salt.The Water Softener units are designed on the advanced Co current/counter-current principle that ensures consistent good quality treated water.A typical water softening Plant consists of pre-filters, Water Softener Vessel with Resin, Brine Tank, and accessories.The Water Softener units are available in a wide range of materials like FRP / LDPE / MS /MS Rubber Lined / Stainless Steel.These Water Softeners come with Multiport Valves/ Diaphragm Valves and designed to give long trouble free service. These Water Softener units are easy to install and does not require any special foundation & needs minimum maintenance. Automatic Twin Water Softening Plant Fluid Systems Offers fully automatic twin Softeners with salt saving technology for producing soft water with low residual hardness. These softeners consume almost 25 % less salt thus saving on the Regeneration costs. Water Softening Plants - Lime softening The Lime Softening Process utilizes the addition of lime (calcium hydroxide) to remove hardness (calcium and magnesium) ions by precipitation. Softening is achieved by adding lime in the form of Ca(OH)2, which reacts first with CO2 to form calcium carbonate precipitate, and then reacts with multivalent cations to remove carbonate hardness, then reacts with anions to replace the non-carbonate hardness due to multivalent cations with non-carbonate hardness due to calcium. Lime softening process produces large volumes of sludge and as such is not used nowadays. We Offer the widest Range of Water Softening Plants in India: FRP Water Softeners up to 2000 mm Diameter MS Water Softeners up to 3000 mm Diameter MS Rubber lined Water Softeners up to 4000 mm Diameter Water Softener -Advantages Easy to install and operate Produces soft , non-scale forming water High capacity Cation exchange resin. Consistent treated water quality Low operating costs Water Softener - Applications Water Softening Plants for Boiler feed water Water Softening Systems for Cooling water make-up Water Softening Plants for Food and beverages Water Softening Plants for Hotels and restaurants Water Softeners for Air conditioning plants Water Softeners for Laundries

...more

Water Filter Spares

With the support of our skilled team, we are engaged in offering a wide assortment of water purifier spare parts. Further, these are available in various standard as well customized specifications to the clients. Water Treatment Spares & Water treatment Components supplied by us:

...more

water filter gravel

Different types of Filter Media are used depending on the raw water quality and the treated water quality required. Extracted from a clean glacial sand deposit, Sai Minerals Water filter Sand physical properties make it among the finest available in the world for filtration applications.

Size : 0.8 to 1.6 mm size.

...more

VFD PRESSURE BOOSTING SYSTEMS

Fluid Systems, with over 15 years experience in the industry, offer a wide variety of pressure boosting systems – standard and custom build to your specifications.The Pressure boosting systems consists of automatic pressure controlled Pumps and a Bladder tank with precharged air. The water is pumped in this tank, which compresses it and pressurizes the bladder, which in turn maintains the desired pressure within the whole system. This automatic system requires no manual intervention and is built for low maintenance. For higher water requirements custom build systems are available with variable speed drives. High fidelity pressure sensors sense the minutest water quantity drawn and the variable speed drive pump delivers the demanded quantity at a preset pressure. Complete and efficient management of water pressure is achieved with lower operation costs. VFD Multiple Pump Operation and Control Constant Pressure is maintained by the VFD in a multi pump system in the same manner as single pump system. The VFD can use up to four pumps to maintain constant pressure. However as the first pump reaches maximum speed; increased demand will cause the pressure drop as the pump runs down its curve. In single pump system, the pump would shutdown at run out, while In the multi pump system, the pressure drop causes the second pump to come online.Special Features Automatic operation of the system Light, Compact and easy to install. Provides strong, even constant water pressure every time. Silent operation. Very durable requiring almost no maintenance. Low operation cost. Monitors water flow and provides for automatic shut off if no water is available, thus eliminating one major cause of pump breakdown/burnout. Provides for automatic shut off at very low water flow levels to protect against cycling. No need of overhead tank provided continuous power is available. Application Ideal for boosting low water pressure in homes where the incoming municipal water supply pressure is inadequate Increase water pressure from underground or surface water supplies Automatic water transfer Applications where pressure "cycling" must be avoided or where the pump may have interrupted water supply Domestic & light industrial irrigation

...more

Ultraviolet Units

Ultraviolet (UV) treatment is a widely recognized and proven method of disinfection of water. It is a physical treatment & doesn't alter the water chemistry. UV adds nothing to the water such as undesirable color, odor, taste or flavor and neither does it generate harmful by-products.Ultraviolet light deactivates the DNA of bacteria, viruses and other pathogens and destroys their ability to multiply and cause disease. Specifically, UV light causes damage to the nucleic acid of microorganisms by forming covalent bonds between certain adjacent bases in the DNA. The formation of such bonds prevents the DNA to reproduce. UV Technology:- For the past 100 years science has recognized the bactericidal effects of the ultraviolet area of the electromagnetic spectrum. The specific wavelengths responsible for this reaction are situated between 240 - 280 nanometers (referred to as nm) with a peak wavelength of 265 nm and are known as UV-C, The degree of UV inactivation of pathogens is directly proportional to the UV dose applied to the water. UV dose is the product of UV light intensity and exposure time and is expressed in mJ/cm2. NSF International has established a UV dose of 40 mJ/cm2 as the minimum UV dose required to ensure that all bacteria, viruses, Giardia and Cryptosporidium are killed / inactivated to a safe level.Fluid Systems manufactures Ultraviolet units in India with the finest 316 Stainless Steel, Electro polished internally as well as externally for years of corrosion free service. The system allows water to come in contact with Ultra Violet rays having 30,000 micro watts second/cm2 UV dosage & 2537 Angstrom (254 nm) units wavelength. The silica quartz jacket provides 100% efficiency due to its pure crystal clear transparency as compared to the Teflon tubes which has only 25% transparency. Fluid Systems offers a complete range of Ultra Violet Units in India, for drinking and process water applications in India with outputs ranging from 100 lph up to 1,00,000 lph. Ultra Violet Units – Advantages More effective against viruses than chlorine - Chlorine is becoming less acceptable because of harmful byproducts, handling problems, & risk of overdosing. Immediate treatment process, no need for holding tanks, & retention times, so footprint is small. Extremely economical due to low capital, operational & maintenance costs. No chemicals added to the water supply – resulting in no byproducts & no need for specialized storage requirements No change in taste, odor, pH, conductivity of water Automatic operation Simplicity and ease of maintenance, periodic cleaning, and annual lamp replacement, no moving parts to wear out Easy installation, only two water connections and a power connection Compatible with any water treatment processes, (i.e. RO, filtration, and softening). Ultra Violet Unit - Applications Drinking water:– Schools & Colleges Residential Factories & offices Ice Making Vending machines Food Processing:- Bottled water Beverages, Fruit juices Breweries & Wineries Medicine: - Pharmaceutical Laboratories Dialysis Pathology labs Wastewater

...more

Ultraviolet Unit

Ultraviolet (UV) treatment is a widely recognized and proven method of disinfection of water. It is a physical treatment & doesn't alter the water chemistry. UV adds nothing to the water such as undesirable color, odor, taste or flavor and neither does it generate harmful by-products. For the past 100 years science has recognized the bactericidal effects of the ultraviolet area of the electromagnetic spectrum. The specific wavelengths responsible for this reaction are situated between 240 - 280 nanometers (referred to as nm) with a peak wavelength of 265 nm and are known as UV-C,

...more

Tube Settlers

Tube settlers use multiple tubular PVC channels at an angle of 60°, adjacent to each other, combined together to form a tube deck, for an increased effective settling area. The flocculated water enters the tube deck from the bottom and flows upward between them. As the water moves upwards, solids settle onto the surface area provided by the tube surface. Heavy Solids continue to slide down the tube surfaces to the collection hopper. Application Areas Raw Water Treatment Sewage Treatment Primary Effluent Treatment Advantages of Tube Settlers The advantages of tube settlers can be applied to new or existing clarifiers/basins of any size: It is possible to cut coagulant dosage by up to half while maintaining a lower influent turbidity to the treatment plant filters. Less filter backwashing equates to significant operating cost savings for both water and electricity. New installations using tube settlers can be designed smaller because of increased flow capability. Flow of existing water treatment plants can be increased through the addition of tube settlers. Tube settlers increase allowable flow capacity by expanding settling capacity and increasing the solids removal rate in settling tanks.

...more

tube deck media

Tube settlers use multiple tubular PVC channels at an angle of 60°, adjacent to each other, combined together to form a tube deck, for an increased effective settling area. The flocculated water enters the tube deck from the bottom and flows upward between them. As the water moves upwards, solids settle onto the surface area provided by the tube surface. Heavy Solids continue to slide down the tube surfaces to the collection hopper.

...more

Swimming Pool Filters

Fluid Systems a company devoted to Water Treatment in India, offers the latest in Pool & Spa technology. We offer a large variety of Pools & Spas including In ground Pools, Semi ground Pools, Concrete & Liner Pools, Portable & In ground Spas, Pool Filtration Systems, Dosing Systems & Accessories.Today, we not only deal in complete range of swimming pools & Swimming Pool Filters but also take up turnkey jobs of swimming pools, Jacuzzi / spas right from conceptualising to installation. Our Technically qualified Engineers and Architects look after the projects; maintain high standards during manufacturing, construction and installation, guaranteeing clients a success in their ventures. Our structures vary according to the type of soil on which the pool is built. We offer pools in any shape, size or depth, thanks to the Surflo systems we offer, the most innovative technology in the industry.As for water circulation and surface cleaning, our technologies have been widely tested in the market; the skimmer and level deck techniques ensure perfect water quality at all times.Swimming Pool Filtration is an essential operation in the Pool working and is guaranteed by our range of high-efficiency Pool filters and pumps with up-to-date pre-filters and other special components. For Pool disinfection, we offer world class dosing systems, to maintain hygiene of the pool.Swimming Pool Filtration, disinfection and cleaning of the pool can be fully automated, thereby enabling your swimming pool to be in operation virtually independent.Regarding the aesthetics, internal lighting is available either with optical fibres or with transformed lamps. The exterior flooring incorporates the craftsmanship of paving blocks/granite sculptors, which render a magical finishing touch. We also ensure the supply and installation of the most reliable products in the market. Surflo System The SURFLO system is based on the following established facts: The diseases contracted by bathers are chiefly those of eyes, ears, nose and throat. The most potent germ-carrier is floating mucus. Maximum pollution occurs at the surface of the water. One of the most important safeguards is the maintenance of a satisfactory chlorine residual in every part of the bath. This is achieved by drawing water continuously from the pool, passing it through a purification plant and returning to the pool. The purification process consists of removal of suspended matter and colour, and destruction of bacteria by sterlisation.Water is to be collected from the pool by the channels formed along the perimeter of the pool. The water overflowing in these channels is supposed to produce a constant skimming effect on the surface, to carry away the dangerous floating mucous and other material. We Offer the below Swimming Pool Equipment in India: Swimming Pool Installation Swimming Pool Filtration Systems Swimming Pool Filtration Plants Swimming Pool Dosing Systems Swimming Pool Filter Sand Swimming Pool suction sweeper Swimming Pool accessories Fluid Systems offers Chemical handling and Dosing Systems for dosing Coagulants like Lime. Ferrous Sulfate, PAC, Alum and Feed Conditioning chemicals like Anti-scalant, Antioxidant, Membrane cleaners etc. Dosing systems are Skid mounted, compact and rugged, engineered to handle and work efficiently under highly corrosive and varying conditions. The areas of application include Raw Water Treatment Waste Water Treatment Reverse Osmosis Ultra Filtration Cooling Water Treatment Boiler Feed Treatment Typical Dosing systems consist of Metering type pumps with varied material of construction to suit the chemical handling. All Dosing Systems can be upgraded to a high level of automation for link up to a localized PLC or client's DCS as required.Pre-engineered designs conform to International safety norms with respective to spillage and containment. Chemical Dosing SystemsClarifierFiltersReverse Osmosis PlantsDM PlantsWater SoftenersSwimming PoolUltraviolet UnitsWater Treatment SparesWater Treatment PlantsRO PlantsPressure Boosting SystemsFilter MediaMineral Water PlantsSewage Treatment PlantEffluent Treatment PlantsMultiport Valves IndiaUlt

...more

solid contact clarifiers

The High Rate Solid Contact Clarifier usually called as HRSCC is used mostly wherein the incoming load conditions vary. Much wider range of water qualities can be handled in the HRSCC Clarifier. The principle is based on mixing existing floc with the incoming effluent, to create a dense floc, which can be easily settled down

...more

Side stream Filters

Side Stream filters are most commonly used for Cooling Tower water filtration. They use relatively coarse sand and other granular media to remove particles and impurities in the Cooling tower water.Water flows through the filter medium under pressure and the suspended particles are trapped in the sand matrix. These filters are typically designed with high filtration velocities.

...more

Sewage Treatment Plants

We provide Sewage Treatment Plants that are designed and manufactured using Activated Sludge Process (ASP) technology. The water treated using our plant can also be used for flushing and washing. We also design plants using other advanced technologies such as MBBR technology, UASB technology and Sequential Batch Reactor (SBR). These technologies are discussed below: MBBR technology: Better performing than ASP, it needs less space and thus saves money. This technique is perfect to use where there is space constraint. The water treated using this technology can even be used for washing and gardening. UASB technology: It is appreciated by the clients for low power consumption as compare to any other technology available in the market. Further, the Biogas generated using this technique can be used for the high capacities plant and to the run the full plant after converting it to electricity. The treated water from this plant can even be used for gardening. Sequential Batch Reactor (SBR): It helps in treating the waste water in Batches and hence it is perfect to use where the waste water generated per day is very low. The technology also helps in saving the running cost and low sludge generation. No need of separate clarifier or settling tank. We offer a huge range of Sewage Treatment Plants, which are used in the national as well as international market. These products are manufactured using latest techniques using modern machines and we offer these products in a cost effective as well as reliable manner. Our products are easily available in different specifications and we check these on the basis of different quality parameter using various quality controller. These products are available with customized services to our clients. Combined Sewage Cum Effluent Treatment Plants We offer a wide range of Combined Sewage cum Effluent Treatment Plants that satisfies two purposes simultaneously. These are efficiently designed to treat and manage both sewage and effluent at the same time. This plant proficiently drains out water from sewage and effluents and hence making it usable for other application such as gardening, farming and washing. Our range of combined sewage cum effluent treatment plants is available in standard specification and can also be customized to meet the varied requirements of our clients. Features: Low cost Compact in size Low electrical consumption Integrated Sewage Treatment Plant We offer an excellent quality range of Integrated Sewage Treatment Plants, which are used for the treatment of both sewage water as well as solid wet waste together. These products are used as an alternative energy source and the treat water is used for different purposes such as farming, gardening, washing and flushing. Our products are available at genuine prices to our clients and these are available on the basis of latest techniques. Uses: Corporate Industries Hotels & Resorts Education Institutes

...more

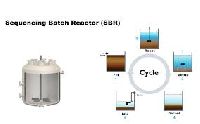

Sequential Batch Reactor

SBR is new technology for the treatment of domestic and industrial wastewaters. The SBR can treat wide range of domestic and industrial wastewaters, at flow ranging from few thousand liters to millions of liters per day. The SBR process can treat any wastewater that can be treated by activated sludge process including anoxicoxic systems, aerated lagoons, extended aeration processes, trickling filters, rotating biological contactors (RBCS) and oxidation ditches.

...more

RO Plant Filter

Reverse osmosis is the process of forcing a solvent from a region of high solute concentration through a membrane to a region of low solute concentration by applying a pressure in excess of the osmotic pressure. This is the reverse of the normal osmosis process, which is the natural movement of solvent from an area of low solute concentration, through a membrane, to an area of high solute concentration when no external pressure is applied. The membrane here is semipermeable, meaning it allows the passage of solvent but not of solute. To illustrate, imagine a semi permeable membrane with fresh water on one side and a concentrated aqueous solution on the other side. If normal osmosis takes place, the fresh water will cross the membrane to dilute the concentrated solution. In reverse osmosis, pressure is exerted on the side with the concentrated solution to force the water molecules across the membrane to the fresh water side.

...more![REVERSE OSMOSIS PLANTS [RO PLANTS]](http://2.wlimg.com/product_images/bc-small/dir_84/2494609/reverse-osmosis-plants-ro-plants-1525254632-3821521.jpeg)

REVERSE OSMOSIS PLANTS [RO PLANTS]

Reverse osmosis is the process of forcing a solvent from a region of high solute concentration through a membrane to a region of low solute concentration by applying a pressure in excess of the osmotic pressure. This is the reverse of the normal osmosis process, which is the natural movement of solvent from an area of low solute concentration, through a membrane, to an area of high solute concentration when no external pressure is applied. The membrane here is semipermeable, meaning it allows the passage of solvent but not of solute.To illustrate, imagine a semi permeable membrane with fresh water on one side and a concentrated aqueous solution on the other side. If normal osmosis takes place, the fresh water will cross the membrane to dilute the concentrated solution. In reverse osmosis, pressure is exerted on the side with the concentrated solution to force the water molecules across the membrane to the fresh water side. The membranes used for reverse osmosis systems have a dense polymer barrier layer in which separation takes place. Since Reverse Osmosis does not occur naturally, it must be created by applying pressure to the high solids water in order to force it through the membrane, with pressures from 8 - 14 bar for fresh and brackish water, and 40 - 70 bar for seawater, which has around 24 bar (350 psi) natural osmotic pressure which must be overcome. Design Considerations for RO Plant Fluid Systems RO Plants work on the Crossflow Filtration method, which takes the feed water and uses a percentage of it as a wash or reject stream, removing the solids during the filtration process.The product flow of an RO Plant is mainly a function of temperature and pressure. System recovery (product divided by feed) is limited by the characteristics of the feed water and can be controlled through the use of recycle stream. Product quality is based on a percentage of dissolved solids fed to the membrane. There should be an economic balance between product quality and system recovery. High recoveries increase concentration of dissolved solids in the system which degrades quality, but high recoveries make the system work more efficiently and decrease waste.Reverse Osmosis Plants do not deliver to service all of the water that is fed to them. During operation, some of the incoming water is used to wash down the membrane, and only part becomes finished product water. Purified water is referred to as product and wastewater is referred to as concentrate, or reject. The percent of water delivered as product is called the recovery, and depends upon the membrane and on total RO Plant design considerations. Pretreatment – Reverse Osmosis Plants The feed water, depending on its source, may contain various concentrations of suspended solids and dissolved matter. Suspended solids may consist of inorganic particles, colloidal particles and biological impurities such as microorganisms and algae. Dissolved matter may consist of highly soluble salts, such as chlorides, and sparingly soluble salts, such as carbonates, sulfates, and silica. During the Reverse Osmosis process, the volume of feed water decreases, and the concentration of suspended particles and dissolved ions increases. Suspended particles may settle on the membrane surface, thus blocking feed channels and increasing pressure drop across the system. Sparingly soluble salts may precipitate from the concentrate stream, create scale on the membrane surface, and result in lower water permeability through the RO membranes. This process of formation of a deposited layer on a membrane surface is called membrane fouling and results in performance decline of the RO system. The objective of the feed water pretreatment process is to improve the quality of the feed water to the level which would result in reliable operation of the RO membranes. Based on the raw water quality, the pretreatment process for RO Plants may consist of all or some of the following treatment steps: Clarification followed by Sand Filtration for Turbidity removal Water disinfection with chlorine Hardness reduction by Softening Addition of scale inhibitor Reduction of free chlorine using sodium bisulfite/ Activated carbon filters Final removal of suspended particles using cartridge filters RO Plants - Post Treatment Based on the Output water quality required, the post treatment process for Reverse Osmosis Plants may consist of all or some of the following treatment steps ozonation Ultra-violet chlorination systems We Offer a wide range of Reverse Osmosis Plants [RO Plants] Residential Reverse Osmosis Purifiers:We Offer a range of RO Water purifiers in 3/5 stage purification modules in below flow configurations: 10 LPH RO Purifiers 20 LPH RO Purifiers 25 LPH RO Purifiers Commercial RO Systems / Institutional RO Systems One of our most popular series, the Commercial RO usually comes in standard Models. These Commercial RO Systems can be customized to add Multimedia Filters & Activated carbon Filters, Water softeners, Antiscalant Dosing Systems, and UV sterilizers.These systems are used to purify water and remove salts and other impurities. It is also capable of rejecting bacteria The Main features of these RO Plants are: Microprocessor based Control Panel Powder coated frame 20 & 5 micron sediment pre-filter Stainless Steel Multistage High pressure pump FRP pressure vessel Product and Reject Flow Meters Low & High pressure switch High rejection TFC membranes Heavy duty high pressure tubing Pressure gauges These Commercial/Institutional RO Systems are available in following Flow Ranges: 200 LPH RO Plants 250 LPH RO Plants 400 LPH RO Plants 500 LPH RO Plants 750 LPH RO Plants Higher flow Rates can also be custom-built as per Customers requirement Industrial RO Plants/ Industrial RO SystemsWe manufacture a wide Range of industrial Reverse Osmosis Plants to cater the stringent process requirements. Our industrial reverse osmosis Plants are carefully customized and configured to suit the individual requirement of the output water, which varies from normal drinking application to the specific usage, such as food Processing, pharmaceuticals and boiler feeding requirement.These systems come standard with pre-filters, chemical dosing and Antiscalant dosing. Customization is available on all our units based on individual water application and customer needs. Microprocessor based Control Panel 4" & 8" TFC spiral wound membranes FRP membrane housings Epoxy painted steel frame Stainless steel High Pressure Multi-stage pump 20 & 5 micron cartridge filter Low & High pressure switch Glycerin filled pressure gauges Permeate & concentrate flow meters Outlet Conductivity meter These Industrial RO Systems are available in the Flow Ranges from 1 M3/Hr Product Water Capacity and above. Standard Ranges are available in Multiples of 1 M3/Hr up to 10 M3/Hr. Higher flow Rates can also be custom-built as per Customers requirement

...more

Reverse Osmosis Plant

Reverse osmosis is the process of forcing a solvent from a region of high solute concentration through a membrane to a region of low solute concentration by applying a pressure in excess of the osmotic pressure. This is the reverse of the normal osmosis process, which is the natural movement of solvent from an area of low solute concentration, through a membrane, to an area of high solute concentration when no external pressure is applied. The membrane here is semipermeable, meaning it allows the passage of solvent but not of solute. To illustrate, imagine a semi permeable membrane with fresh water on one side and a concentrated aqueous solution on the other side. If normal osmosis takes place, the fresh water will cross the membrane to dilute the concentrated solution. In reverse osmosis, pressure is exerted on the side with the concentrated solution to force the water molecules across the membrane to the fresh water side.

...more

Raschig Rings

Raschig rings are pieces of tube (approximately equal in length and diameter) used in large numbers as a packed bed within columns for distillations and other chemical engineering processes. They are usually provide a large surface area within the volume of the column for interaction between liquid and gas. They form what is now known as random packing, and enabled Raschig to perform distillations of much greater efficiency than his competitors using fractional distillation columns with trays.

...more

Pressure Sand Filters

These filters are the most popular method for removal of turbidity from water. The Pressure Sand Filter consists of a multiple layer of sand with a variety in size and specific gravity. These Filters are designed to remove turbidity and suspended particles present in the feed water with minimum pressure drop. These Filters are custom designed to suit the process requirement. These filters are offered in Mild Steel, FRP or SS construction with face piping and associated Valves. Construction The Pressure sand filter consists of a pressure vessel either vertical or horizontal, with a set of frontal pipe work and valves, graded silica quartz sand supported by layers of graded under bed consisting of pebbles and gravels, a top distributor to distribute the incoming water uniformly throughout the cross section of the filter, and an under drain system to uniformly collect the filtered water. Process Raw water flows down wards through the filter bed and as the suspended matter, which is treated by addition of a coagulant like alum or poly electrolyte, is retained on the sand surface and between the sand grains immediately below the surface. There is steady rise in the loss of head over a period of time and the flow reduces once the pressure drop across the filter is excessive.The filter is then taken out of service and cleaning of the filter media is effected by flow reversal also called as backwash. To assist in cleaning the bed, the backwash operation is sometimes preceded by air scouring by way of agitation through the under drain system. The air scouring agitates the sand with a scrubbing action, which loosens the intercepted particles. The filter is now ready to be put back into service. We Offer the following Range of Pressure Sand Filters: FRP Pressure Sand Filters up to 2000 mm Diameter Vertical MS Pressure Sand Filters up to 5000 mm Diameter Horizontal MS Pressure Sand Filters up to 4000 mm Diameter Pressure Sand Filter - Salient Features: Efficient Turbidity Removal MOC - FRP, MSRL, MSEP & SS Standard and effective multi grade sand media. Low Pressure drop across the vessel Optional Air scouring available. Manual, Semi Automatic & Automatic Options Fluid Systems offers Chemical handling and Dosing Systems for dosing Coagulants like Lime. Ferrous Sulfate, PAC, Alum and Feed Conditioning chemicals like Anti-scalant, Antioxidant, Membrane cleaners etc. Dosing systems are Skid mounted, compact and rugged, engineered to handle and work efficiently under highly corrosive and varying conditions. The areas of application include Raw Water Treatment Waste Water Treatment Reverse Osmosis Ultra Filtration Cooling Water Treatment Boiler Feed Treatment Typical Dosing systems consist of Metering type pumps with varied material of construction to suit the chemical handling. All Dosing Systems can be upgraded to a high level of automation for link up to a localized PLC or client's DCS as required.Pre-engineered designs conform to International safety norms with respective to spillage and containment.

...more

Multiport Valves

We supply Multiport valves [MPV] for wide range of applications. Multiport valves are used in filters, softeners, Mixed Bed exchangers and DM Plants. Our products are broadly categorized as follows: Full/Semi Automatic multiport Valves Manual Multiport valves Distribution Systems for FRP vessels Accessories Manual Multiport ValvesWe Supply Manual Multiport valves in below Range: 20NB(20mm) Multiport Valves 25NB(32mm) Multiport Valves 40NB(40mm) Multiport Valves 65NB(65mm) Multiport Valves Accessories - Manual Multiport Valves Multiport Valve Ejectors Brine Directors Air Release valve Automatic Multiport ValvesWe Supply Automatic Multiport valves in below Range: 20NB(20mm) Auto Multiport Valves 25NB(32mm) Auto Multiport Valves 40NB(40mm) Auto Multiport Valves Distribution Systems We supply Distribution systems ranging from 5M3/Hr to 40M3/Hr for FRP vessels

...more

MBBR Media

Domestic and Industrial Wastewater. Package Plants for Wastewater. Paper and Pulp. Wineries. Most Organic Wastewater. Nitrification de-nitrification Makes very compact wastewater plants, robust and stable operation, no backwash required, no membranes, self cleaning media, never need to replace.

Color : Black

...more

Lamella Clarifier

Inclined plate type clarifier used for clarification of water & waste water having higher suspended and colloidal particles. The principle is based on settlement of colloidal particles by providing a series of inclined plates, which are arranged to form a separate sedimentation chamber between adjacent plates.The Lamella Clarifier provides a means of water clarification at a large saving of surface area. (Up to 90 %)

...more

Iron Removal Filters

The Iron Removal Filters are designed to remove the Excess Iron content present in the feed water with minimum pressure drop.Most iron filtration systems operate on the principal of oxidizing the iron (oxidation) to convert it from a ferrous (dissolved or soluble) to a ferric or undissolved state. Once the iron is converted to ferric state, it is precipitated on a filter bed.For low Iron content in feed water, the Filter consists of Manganese Zeolite, where the iron is oxidized to insoluble hydrated oxides that are removed by the mechanical filtering action of the Zeolite bed.

...more

HRSCC - HIGH RATE SOLID CONTACT CLARIFIERS

Fluid Systems Manufacture a Wide range of custom-built High Rate Solid Contact Clarifier – HRSCC in India for industrial process water applications, with inherent design to conserve water, and save costs.The High Rate Solid Contact Clarifier usually called as HRSCC is used mostly wherein the incoming load conditions vary. Much wider range of water qualities can be handled in the HRSCC Clarifier.The principle is based on mixing existing floc with the incoming effluent, to create a dense floc, which can be easily settled down HRSCC - Application Areas Colloidal Silica Removal Waste Water Treatment Heavy Metal Removal. Advantages of the HRSCC The solids contact type clarifier or HRSCC is a high rate water treating clarifier, which produces treated water of highest quality with minimum time, space and chemicals. In high rate solids contact type clarifier, coagulants and large quantities of recirculating sludge’s are thoroughly mixed and are retained in intimate contact for a prolonged period of time in the draft tube and cone sections of the solid clarifier. The tank and structural support design is completely self supporting for continuous service and compatible for supporting external loads such as walkways, ladders etc. Minimum building space requirements and building height clearances. Simple and straight forward operation requiring less operator attention and minimum maintenance.

...moreBe first to Rate

Rate ThisOpening Hours