Wireless Trap Monitoring System

In the course of operation, keeping track of trap performance and repairingreplacing leaking or waterlogged trap becomes unfeasible due to the large number of traps installed.

...more

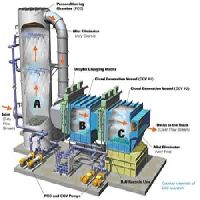

Welcome to Forbes Marshall Codel

For more than six decades, Forbes Marshall, has been building steam engineering and control instrumentation solutions that work for process industry. We are probably the only company in the world to have extensive expertise in both steam and control instrumentation. This dual expertise has allowed us to engineer industry specific systems that focus on energy efficiency and utilities management for sectors as diverse as textiles, food processing, paper, power and chemicals. We realize our social and ecological responsibility and with every new development, we emphasis our regard for the environment and the people who are a part of it. Corroborating our efforts towards a clean and safe environment, we bring you the Forbes Marshall Codel Continuous Emission Monitoring System alias the SmartCEM system. Codel International Ltd is a UK based company in Bakewell, Derbyshire, specialising in the design and manufacture of high technology instrumentation for combustion processes and atmospheric pollution emissions from last two decades. The company policy is simply to design well engineered, rugged, reliable equipment, capable of continuous operation over long periods with minimal maintenance.

...more

Water Pressure Reducing Valve

Steam boilers are usually designed to work at high pressures. Working them at lower pressures can result in carry over of water. Steam at high pressure has a lower specific volume which means that a greater weight can be carried by a pipe of a given size. We recommend distribution of steam at high pressure and reduction at the point of usage. This reduces capital loss for piping and insulation and also reduces distribution losses. Steam pressure may be reduced to save energy. Steam at lower pressures has higher latent heat. Reduced pressure of steam also leads to reduced heat loss and lower flash steam formation from open vents etc.

...more

Waste Heat Recovery Boilers (WHRB)

Forbes Marshall Exhaust Gas/ Waste Heat Recovery Boilers (WHRB) are fully packaged smoke tube industrial boilers equipped with advanced instrumentation to deliver maximum possible heat recovery. These boilers are ideal to recover heat from gen sets, incinerators, blast furnace exhausts etc. They enhance the system efficiency and help save fuel and money. All Forbes Marshall exhaust gas/ waste heat recovery boilers are designed for easy inspection and maintenance. Every boiler is manufactured with latest submerged arc fabrication technology to ISO 9001, IBR standards. Features 1. Modulating Diverter Damper with Sealing Efficiency of 99.9%2. Smart Boiler with Heat Recovery Calculator3. Interlock between of Diverter Damper & Outlet Motorized Valve4. Regulated Movement of Diverter Damper5. High Sinking Time6. Dryness Fraction – 98.5 %7. Single Element Control incase of Economiser8. Sonic Soot Blowers for Online Cleaning (For FO fired Gensets)9. All Steam Line & Water Line Valves are Piston Valves

...more

Waste Heat Recovery Boilers

Forbes Marshall Exhaust Gas Waste Heat Recovery Boilers (WHRB) are fully packaged smoke tube industrial boilers equipped with advanced instrumentation to deliver maximum possible heat recovery. These boilers are ideal to recover heat from gen sets, incinerators, blast furnace exhausts etc. They enhance the system efficiency and help save fuel and money.

Specialities : High Sinking Time and All Steam Line & Water Line Valves are Piston Valves

...more

waste heat boilers

These boilers are ideal to recover heat from gen sets, incinerators, blast furnace exhausts etc. They enhance the system efficiency and help save fuel and money.

...more

Vibration Monitoring MAchine

Vibration monitoring is essential to keeping rotating equipment running smoothly for years. Shinkawa Vibration Monitors are an indispensable complement to equipment like pumps, motors, fans, compressors, and turbine supervisory systems. Monitors are available in single channel, four channel or multichannel versions.

...more

Ultrasonic Flowmeter

Easy to install and operate. No moving or intruding parts, no wear, no drift, therefore no additional pressure loss. No material build-up as unobstructed flow sensor with smooth surface finish. No periodic re-calibration or maintenance. Insensitive to corrosive or abrasive products. Excellent long-term stability and reliability.

Specialities : Non intrusive , No moving parts and No wear

...more

Turbidity Analyser

The optical windows are made of hard-toscratch sapphire glass. This facilitates scrubbing of the window surface to keep the turbidity sensor clean.

...more

Toc Analyzer

As standard it has automated zero, calibration, sample and wash sequences which enable the system to run on the dirtiest of samples.

...more

temperature valves

that can offer a comprehensive variety of valves for high pressure and high temperature applications for various sectors such as Power Plants, Oil and Gas, Chemicals, Petrochemicals, Paper, Sugar and Steel.

...more

Swing Check Valve

There are many disk and seat designs available, in order to meet the requirements of different applications. The valve allows full, unobstructed flow and automatically closes as pressure decreases. These valves are fully closed when flow reaches zero, in order to prevent backflow.

Feature : Swing Check Valve and Valve Digest

...more

steam pumps

In order to keep energy requirements minimum, it is important that condensate is handled efficiently and energy from the condensate is recovered. Recovering condensate leads to many benefits such as reduced fuel and water bills, lower water treatment costs etc. and hence, condensate should be recovered.

Feature : Tested for 1 million cycles , Works on steam/air

...more

Steam Pipe

Steam Pipes Sizing or Correct sizing of steam lines reduces pressure drop and radiation loss. Steam pipes that are undersized cause high pressure drop and result in steam starvation at the point of usage. Conversely, over sized steam pipes, are in no way detrimental to the operation of the plant but lead to an unnecessary increase in the capital cost of installation. In addition over sized pipes also increase the running costs due to radiation losses

...more

Steam Distribution Header

So when we recommend a trap for your application, you can be sure it meets your requirements perfectly, not just our product range. Our Metering systems tell you exactly how much steam is going where. Our Pressure reducing stations ensure a fine control on pressure and temperature.

...more

Steam Desuperheaters

The most practical way of reducing the superheat value of steam is by the direct addition of water. To achieve temperature stability of the conditioned steam and prevent thermal shock in downstream pipes, cooling water must be atomized. It is also necessary to have a correct mix of superheated steam and cooling water.

...more

Steam Boilers

We offer three pass, wet back, fully packaged boilers, equipped with monobloc burners to deliver high combustion and thermal efficiencies. This range comprises of packaged boilers from 6 TPH to 25 TPH, designed to fire liquid and gaseous fuels, the most common being furnace oil and natural gas. These boiler are compatible to all leading imported burners.

...more

spring loaded valves

Forbes Marshall spring loaded disc check valves offer a tight shutoff and are available in a large range of sizes. These valves are compact in design as compared to the conventional swing and lift type of disc check valves. They can be easily mounted in between flanges in any direction. These valves are compatible with both PN and ANSI flanges.

...more

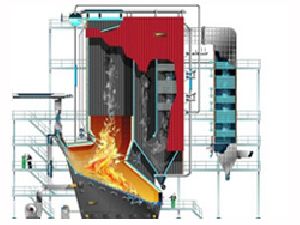

solid fuel fired boilers

Intell SeriesSolid Fuel Fired Boilers The Intell series of boilers is a truly packaged and compact range, available in capacities of 0.6 TPH to 4.5 TPH. The necessary automation for fuel feeding, air to fuel ratio, cut off/ cut in of boilers are inherent in design along with safety features. Inputs on parameters are provided via alerts, to help optimize operations, reduce fuel costs and get quality steam.

...more

pressure safety valves

It can also be advantageously used for most other applications on gases vapours, liquids and saturated steam systems involving small discharge capacities. The SRV12 Series valves are specially designed for steam but can be used on, liquids and gas as well. The valves are designed as per API 526 and meet the requirements of ASME Sec VIII-Division. SRV12 Valves are offered with IBR Certification Form III-C. The valves have a solid nozzle screwed into the valve body and is fully guided at the upper section of the valve body, increasing the strength of the valve assembly. Specially designed disc holder ensures full lift within 5% increase of pressure above the set pressure value. i.e. Over-pressure of maximum 5%. Blowdown of a maximum of 5% is achieved in this design. Superior lapping of the seat area ensures a high level of leak tightness at seat. Disc lifts above 14 of nozzle diameter which ensures that the certified flow of the safety valve is discharged. The Spring is selected and assembled with great care so that the valve operates precisely and a good leak tightness is achieved.

...more

Desuperheating Stations valve

We offer customized solutions with total system end to end station with all necessary mechanical and instrumentation components and take guarantee of entire control system.

Feature : The entire assembly is hydro tested.

...more

power boilers

One of the most important tasks in the 21st century is to guarantee sustainable and environmentally- friendly energy supplies in the global effort to protect our climate, nature and the environment. FORBESVYNCKE takes the lead in playing a vital and dynamic role by establishing biomass-based energy providers. Entering the market with an innovative and efficient steam boiler concept, it was intelligently designed to use a wide range of biomass to generate energy efficiently while anticipating future stricter emission regulations. An essential element to its design is the ability to use a multiple choice of biomass resources. To generate electricity, the power plant is fuelled mainly biomass and industrial waste and delivering a greener footprint for every KWe. With cogeneration solutions, the overall energy efficiency reaches up to 83%, which is significantly higher than the efficiency of conventional systems generating electricity and heat separately. Cogeneration is the sequential generation of two different forms of useful energy - electrical and thermal

...more

Positive Displacement Type Flow Meters

Positive displacement type flow meters divide the fluid in measured portions and then pump it. The flow can be calculated by multiplying the number of strokes with volume of fluid pumped in each stroke. These flow meters are accurate and deliver precise quantities of fluid.

...more

Portable Ultrasonic Flow Meter

. It is just as easy to use the device for data logging. Data is saved to a USB stick and transferred to external evaluation systems. Its ease of use and flexibility make the OPTISONIC 6400 the ideal solution for flow measurement in a variety of applications in virtually any sector of industry.

...more

Waste Heat Recovery System

Wastewater temperature is major form of pollution. In dyeing processes, so much hot water is discharged that, in the absence of any counter-measures, total wastewater temperatures may exceed 40°C, even though 35°C is the maximum permissible temperature. This new regulatory effort comes at a time when textile companies are already faced with the need to reduce costs to respond to increasing competition.

...moreBe first to Rate

Rate ThisOpening Hours