Vacuum Testing Units

Vacuum Pressure Test OR Aluminium Porosity Test ( Vacuum Testing Units ) In Quality management of Aluminium Alloy Casting, porosity is a major factor which is detrimental in terms of surface quality, corrosion resistance and mechanical properties. Hydrogen, which easily dissolves in molten aluminium which causes gas porosity. Vacuum Pressure Test is the most widely used technique in aluminum foundries. Vacuum pressure test is solidifying a sample of molten aluminium under reduced pressure (vacuum) up to 500mmHg. The reduced pressure enhances pore formation and pore expansion, giving out a visibly more porous sample than that solidified under atmospheric conditions. Porosity assessment is done in the following manner: • Viewing the top of the sample. A puffed up surface indicates heavy gas content, where as a smooth & / or a concave surface indicates mild or acceptable gas content. • Cutting the sample & comparing the cut surface with a photographic standard. Some of the features of our machine are: Self sealing vacuum chamber. In-line suction filter for maintenance-free operation . Filter is designed for easy & fast cleaning. Vacuum display on the Vacuum pressure guage. Three phase unit with all protection. Has overload protection. Can be made mobile

...more

Special Purpose Machines

We are offering a wide range of Special Purpose Machines (SPMs) that is highly appreciated by our clients for attributes such as abrasion resistance, longer service life and precise functioning. These are manufactured using high grade raw material and advanced technology in order to ensure efficient work output that sufficiently cater to the requirements of varied industries. Our complete range is dimensionally accurate and delivers superior performance. Moreover, we also customize these machines as per the specifications laid down by our clients. Some of the SPM that we are offering are as follows :

...more

Scissor Lifts

We offer high quality Scissor Lifts that is developed using finest quality inputs. Our gamut is hydraulically operated by using latest hydraulic technology. These are available in various forms like single, double or multi stage Scissor Liftss. Our Scissor Lifts exhibit following salient attributes: High pay load capacity up-to 1200kg. Robust structure. Low closing height feasibility up-to 200mm. Cartridge type manifold assembly.(optional). Easy for the maintenance. Guided roller. Sudden fall safety through hose burst valve. Low operating pressures. Applications Area: Automobile industry Pharmaceutical industry Garage application Maintenance application (Mobile)

...more

Roller Conveyors

21,000 Per Piece

Material : MS,SS

Material Handling Capacity : 150-200 kg per feet

Type : Roller Conveyors

Length : 40-60 feet

...more

Pu Roller Conveyor

This is useful in heavy & light Industry. This is free tyoe conveyor to avide metal to metal contact. Pu Roller Conveyor to use both side bearing for smooth working. Width & sizes is depend on customer requirment.

...more

Pneumatic Press

65,000 Per Piece

1 Piece (MOQ)

Max Force or Load : 30-60 ton

Pneumatic Lifter

We offer Pneumatic Lifter which are stringently checked by our quality checkers on various parameters and then are delivered within a stipulated time frame.Further, our range of Pneumatic Lifter is well known for their efficiency and reliability and is widely used in various industries.

...more

Plastic Slat Conveyor

This is useful for Automatic & Auto Industry, Precision Engg.Industry, Food industry, Beverages & Soft Drink Industry, Medical, Pharmaceutical, Cosmetic, Electric Industry etc. Also avilable in sizes redius, stright & 90deg. As per customer requirement.

...more

Manipulators

We Offer wide range of Manipulators. With the introduction of the manipulator, an employee previously required to lift television sets from the conveyor belt straight onto a pallet could now become the machine's operator, using it to transfer the set from the conveyor belt directly onto a pallet in the adjacent storeroom 6 metres away.

...more

Industrial Pallet Handling

Over the years Garud Automation has design a variety of pallet handling conveyors for heavy duty applications for more information on our pallet range please go to our dedicated page by clicking here

...more

Industrial Conveyors

We are offering a comprehensive range of Conveyors that forms an adequate material handling solution at work. These are manufactured using high grade raw material and are acknowledged for precise functioning and durability. Available in different designs and sizes, their usage expedites the transfer process and eliminates excessive labor.Moreover, we also offer customization facility to our clients.

...more

Hydraulic Press SPM Type

We manufacture of different type of Hydraulic Press PLC Base & without PLC Base this is very simple & user friendly. As per coustamer requirment. Both hand safety push button are provided. This is useful for Bearing Pressing, Bush Pressing, Valve Seat & Valve Guide Pressing, Oil Seal Pressing, Cap Pressing, Shaft Pressing etc.

...more

Hydraulic Press

We are engaged in the manufacturing of high quality hydraulic presses that are employed in simple and intricate transfer moulding of bakelite. Our hydraulic bakelite presses are used in various industries, primarily in the automotive industry. The key features of the press include: Durability Robust framework In-built features that facilitate easy operation and safety Cost effective

...more

Gravity Roller Conveyors

We offer wide range of Gravity Roller Conveyors which is used for delivering cost effective and virtually maintenance-free handling of goods in various industrial applications. These gravity roller conveyors find application in warehousing, production lines, accumulation at start or end of powered conveyors & manual assembly lines.

...more

Flat Belt Conveyors

Garud Automation range of hard wearing belt conveyors giving many years of reliability.Our aim is to build a lasting relationship with our clients and offer the complete package. Can we Help You?Garud Automation welcomes a challenge and offers our assistance with the development of your production processes.Each of our conveyors is engineered to handle your products carefully.Materials used to fabricate the frame are usually dictated by your industry we offer stainless steel, mild steel and aluminum; Belting is also variable and includes; PVC Polyurethane Silicon Resin PU Belt Teflon Plastic Belt / Modular Belt Felt Rubber Wire Belt Garud Automation are able to integrate our conveyors into existing machinery with the little disruption to normal production process. Industries we supply to include. Logistics & Transport Building & Construction Industrial Applications Conveyor Belts how versatile are they? Belt sizes start at approximately 100mm up to 1000mm as standard but we can offer much widerbelts for special applications.Side Guides can be added to restrict your products if desired. Elevating your materials on inclines or declines is achieved by fixing flights to the belt.The number of flights and what pitch will be dictated by the angle desired and your product. Speed can be varied by adding an inverter of mechanical variator and typically can run 2m/min to 50m/min defendant on product. For convenience of transporting your belt conveyor it can be made portable by adding casterswhen the legs are being fabricated. We are able to supply belt conveyors that will accommodate bends and corners. Bespoke Systems designed to carry tubes, Modular Belt Conveyor transporting packs of rice using plastic belt and gravity rollers. Magnetic Conveyor used to convey empty cans for a food factory into the processing areas for filling and packing. New product our Close Transfer Conveyor Tube Sorting Conveyor System Side Grip Belt Conveyor which is fully adjustable to suit different size products. Sortation Twin Lane Conveyor Trial system set up for a company to try their products on one of our Inclined Belt Conveyor. Plastic Modular Belt Conveying loose and packed wet wipes.

...more

Electric Scissor Lifts

125,000 Per unit

Color : green

Degassing Units

We are instrumental in offering a comprehensive range of Degassing Units, which is a foundry treatment system, mainly used for the removal of hydrogen gas and non- metallic impurities from aluminum alloys. These units use inert gas that is delivered to the base of the melt via a uniquely designed spinning rotor. It is manufactured utilizing quality graphite and is designed to ensure maximum contact between metal and purge gas.The rotor of the unit produces a cloud of very small gas bubbles that effectively purge the melt, removing hydrogen and oxide inclusions as the gas rises to the surface. Moreover, the process is also designed to be non-turbulent so that the reintroduction of hydrogen and the regeneration of oxides are reduced to an absolute minimum.During the melting procedure, aluminum produces a lot of oxide and dross, when the mould is poured without removing the dross. The use of inert gas system in the complete process of degassing unit reduces the need for pollution control and gives improved working environment for the operators as well as eliminate toxic emissions & discharges to the surroundings. Benefits Environment friendly process due to use of inert gas systems Elimination of human error since process is automated Higher degassing efficiency (lower levels of gas in less treatment time) Consistently lower levels of gas content (reproducibility & repeatability of results) User friendly operations, easy replacements of graphite consumables Lowest gas levels attained Efficiency maintained through the life of the rotor Oxidation resistant, highest quality graphite to increase life Optimum bubble size and distribution Turbulence free Fast degassing Precautions : Power supply for DU should be 415V A.C. While replacing components the electrical supply should be disconnected fromthe 415 V supply outlet and the control panel MAIN switch should be in OFF position Metal should not be poured or drained out at any time unless water accumulation is removed The quality of inert gas used with the Degassing Units is the direct responsibility of the user All personnel in the vicinity of molten metal must wear proper face and eye protection, heat protection and body protection Accumulation of water anywhere near the vicinity of molten aluminum creates an explosion Use hand gloves for any activity near the hot degassing shaft & rotor to avoid severe burns

...more

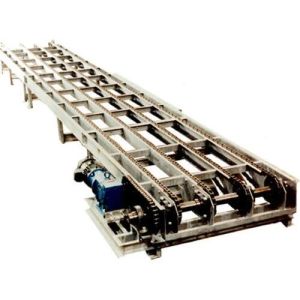

Chain Conveyors

23,400 Per Meter

Length : 20-40 feet

Material Handling Capacity : 50-100 kg per feet

Type : Chain Conveyor

Automation Grade : Semi-Automatic

Belt Material : steel

...more

Belt Conveyor

18,500 Per Piece

Usage : Pharma

Capacity : 50 to 100 (kg/feet)

Type : Flexible Conveyors

Material : MS SS304 & Al. Profile.

Belt Material : PVC

...more

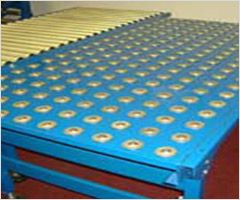

Ball Table Photo

Bulk Material Handling Solutions at Low CostsProviding cutting edge solutions for bulk handling for all industries.If its achievable Garud Automation will find the solution best suited to your products or waste.

...more

Articulated Jib Crane

140,000 Per unit

1 unit (MOQ)

Assembly Conveyors

Leading manufacturer and supplier of a wide range of Industrial Process Equipments. We Garud Automation are leading manufacturer and supplier of Assembly Line conveyor.

...more

sorting conveyor

manufacturer and supplier of Flat belt roller conveyor. Belt sizes start at approximately 100mm up to 1000mm as standard but we can offer much wider belts for special applications. Side Guides can be added to restrict your products if desired. Elevating your materials on inclines or declines is achieved by fixing flights to the belt. The number of flights and what pitch will be dictated by the angle desired and your product. We are able to supply belt conveyors that will accommodate bends and corners. Tube Sorting Conveyor System, Side Grip Belt Conveyor which is fully adjustable to suit different size products.

...more

gravity rollers

We offer wide range of Gravity Roller Conveyors which is used for delivering cost effective and virtually maintenance-free handling of goods in various industrial applications. These gravity roller conveyors find application in warehousing, production lines, accumulation at start or end of powered conveyors & manual assembly lines.

Weight : 10kg, 15kg, 20kg.

...moreBe first to Rate

Rate ThisOpening Hours