Welding Track Vacuum Mounting System

The Gullco vacuum mounting systems are designed to firmly hold the KAT® Rigid and Flex Tracks in position on magnetic and non-magnetic materials. The systems are rugged and dependable while incorporating a light weight design for portability. There are Vacuum KAT® carriage packages specifically designed for automatic welding and cutting applications. PORTABLE VACUUM UNIT Model GV-168-50 Comprised of electric motor driven, 2.4 cfm capacity vacuum pump mounted on cylindrical safety reservoir. Complete with vacuum gauge, filter, non-return valve, necessary fittings and 10 ft. (3048 mm) of flexible hose with quick disconnect coupling. *Recommended 3 pieces of GK-165-054 Rigid or GK-192-F-054-2 Flexible Track per vacuum pump.

...more

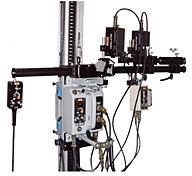

Welding Positioner

Gullcos Welding Positioner is a positive drive rotary turn table complete with mounting flange, drive and tilt mechanism and Microprocessor based pulse width modulation motor control. Standard and Programmable models are available. The welding positioner is driven by a low voltage permanent magnet motor and gearhead power unit assembly. The microprocessor motor control enables operator interface of start, stop, clockwise rotation, neutral, counter clock-wise rotation and infinitely variable control of the speed, within the range of the positioner model. The weld positioners rotation speed is electronically controlled using an optical tachometer located on the back of the gear-motor. Speeds within the range of the model are infinitely variable in both clockwise and counter-clockwise directions through a rotary speed adjustment potentiometer located on the remote control. Table tilt is manually set at any desired angle, from 0º through 90º, quickly and easily. Safety while using the positioner is greatly enhanced with Gullco's low voltage (24 V) control and power supply system.

...more

Welding Electrode Stabilizing Ovens

These Gullco Stabilizing Ovens have gained international recognition and acceptance based on a variety of quality and performance features including.... compact, modular design with controls recessed for protection. shelves easily removed to accommodate large size loads. oven fully insulated to prevent heat loss....pilot light indicates oven operation. thermostat control, incorporating onoff switch, maintains oven temperature in 37.8º - 287.8º C range. models 125 and 350 feature nesting feet and

...more

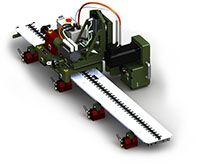

Weld Shaver

The weld shaver carriage uses force compliance to allow the weld shaver head to maintain contact over contoured surfaces and ensures a consistent and precision weld removal. The weld shaver removes up to 90% of the weld height at a rate of up to 3 ftmin (61 cmmin) and can remove welds of 0.375 - 3 Inches (0.9525 - 7.62 cm). The weld shaver system is an automated solution for the rapid removal of weld beads above a panel surface. The Weld Shaver is moved along a track by the Drive Carriage with the user managing everything remotely from the Control Console. The TWS91 System is comprised of five major components; the Track (either Flex or High-Flex), the Drive Carriage, the Weld Shaver, the Control Umbilical, and the Control Console.

Features : Operator Safety,Cutter Insert Life

...more

Trackless Fillet Welding Carriage

The 400 MOGGY® is a trackless welding carriage with an integrated wire feeder, used to automate and improve manual welding processes in Shipbuilding, Tank Construction, and other heavy fabrication applications. The carriage is a lightweight, portable, four wheel friction drive travel carriage that can be used with or without track to automate welding operations. A speed potentiometer provides infinite speed selection within the speed range. The 400 MOGGY® can be adapted for use on standard 6" (152.4mm) v-groove track by reversing the wheel assemblies. Safety is assured by using Gullco low voltage 24 volt DC highly advanced control power supply system that is available in 3 line voltage inputs 42, 110 and 230 volt AC 5060 Hz.

...more

Submerged Arc Welding System SAM

The versatility and reliability of the world famous Gullco MOGGY®trackless travel carriage system and a variety of quality engineered components combine to provide a highly flexible self-contained welding unit. This Gullco unit is designed to produce precision, quality Submerged Arc or MIG welds. SAM®Carriage, Model GM-02-295 - Friction drive heavy-duty travel Carriage, with positive chain drive on four (4) rubber tired wheels using a closed loop tack feedback for accurate speed control. Carriage controlled by the Gullco low voltage 24 volt GSP microprocessor pulse width modulation motor control, all mounted in a remote pendant control box attached to 8 ft. (243.84 cm) control cable housing the GSP control providing the forwardstopreverse switch and infinitely variable 4-turn speed potentiometer. LED display in IPM or cmmin. An interface cable assembly allows the Miller HDC 1500 DX to control the runstop function of the SAM®Carriage. A manual clutch enables free wheeling. Carriage complete with a main mounting mast and handle assembly, mounting arm for one wire reel, all mounting arms equipped with quick jaw mast clamp assembly; vertical and horizontal manual 4" x 4" slides (with hardened ground rods with sleeve bearings for ease of adjustment). Control support arm and one (1) set (two[2]) adjustable guide roll arms. For operation on either 42115230 volts, single phase, 5060 Hz AC power supply. SAM®Carriage, Model GM-02-275 - SAM®Heavy-Duty Friction Drive Carriage for mounting customer's supplied single sub-arc package. Carriage specifications same as model GM-02-295. No welding equipment is supplied. GM-02-250 SAM®Heavy-Duty Friction Drive Carriage Carriage specifications same as that of the GM-02-295, but provided with 17" x 22" (43.18 x 55.89 cm) aluminum plate providing full flat mounting surface for customer's supplied wire feeder.

Voltage : 115 V,230 V,115 V

...more

Rigid KAT Tracks

KAT® Track is manufactured in "Standard" and "Deep" sections...each designed to suit a specific range of applications. Both are made to the highest quality levels and incorporate the following top performance features: Precision Extruded Aluminum Track - made from aluminum that is solution heat treated and artificially aged to produce an alloy having excellent mechanical and corrosion resistant properties. The track is light but strong and the standard section can be readily formed to suit the work contour. Supporting Steel Rack - is securely fixed to the KAT® track to provide a smooth, positive drive. The long-life rack easily supports the KAT® carriage under maximum load when used in a vertical plane. Interchangeable End Design - enables any two lengths of track to mate accurately and, because of symmetry of design, track lengths can be turned end to end. It is even possible to mate standard and deep track sections. Fast, Easy Joining - with combined dovetail and taper screw that provides accurate location between mating track lengths. The track can be joined in the time it takes to tighten two knurled thumb screws. Versatile Mounting - Both standard and deep section tracks have fixing holes on 6" (152.4 mm) pitch along their entire length to provide ample means for mounting or securing brackets. Also Available...Custom Formed Rigid Track Gullco provides complete KAT® Track forming services to customer specifications. Contact Gullco for detailed information.

Length : 48 in1219 mm,120 in3048 mm,96 in2438 mm

Weight : 2 lb/ft3 kg/m

...more

Portable Welding Electrode Stabilizing Ovens

Theyre lightweight, rugged and completely portable...easy to load, easy to carry...ready to provide low cost control of welding quality in the shop or in the field. Reduce operating costs by providing your welding operators with fast access to electrodes at the point-of-work. There's a model exactly suited to your requirements. Weight capacity depends on welding electrode length

...more

Porta Welder - Welding Manipulator System

Designed to bring the weld to the joint, the Porta-Welder is a self contained welding station and a convenient option for pipe and small tank manufacturers looking to improve the efficency of their welding operations. Ideally suited for small facilities or as a supporting option for larger dedicated welding systems. The telescoping boom provides a small footprint when the machine is not in use. Wheels and forklift pockets allow for ease of movement. The Porta-Welder can be equipped with a variety of welding heads and outfitted with a number of different accessories and options. less

...more

Plate Beveller KBM-18

Plate Bevelers, Self Propelled, Portable - KBM-18® produce clean machined bevels with no thermal distortion on mild steel, stainless steel and aluminum plate from 14" (6.0 mm) to 1 12" (38.1 mm) thick. Thinner material can be beveled... consult factory for details. The KBM-18® bevels the topside of plate reducing time and cost. Savings are further enhanced when the topside Beveler is used with the KBM-18U underside beveler in applications where both sides of the material require beveling.

...more

Pipe Welding Carriage

The Pipe KAT® is a pipe welding carriage designed for orbital welding. It is an electrically powered track guided carriage that operates in the forward or reverse directions at precisely controlled speeds. The carriage operates on a track band made of durable aluminum extrusion by engaging the track with self-algining wheels and a rack and pinion drive. This wheel assembly uses a lever to engage that track making it very quick and simple to install the carriage. The Pipe KAT® is a fully integrated welding system which comes with a wire feeder and wire spool holder. Driven by a 24 VDC motor which feeds wire to the welding torch at precisely controlled speeds. The wire spool holder accepts standard 8"10 lbs (20.3 cm4.5 kg) spools. A remote control pendant is provided to allow adjustment of the critical application parameters during the welding process including, oscillation width, speed, dwells, wire feed speed and voltage adjustment.

...more

Pipe Welding Carriage

The Pipe KAT® is a pipe welding carriage designed for orbital welding. It is an electrically powered track guided carriage that operates in the forward or reverse directions at precisely controlled speeds. The carriage operates on a track band made of durable aluminummore

...more

Overlay Cladding System

The Gullco Overlay Cladding System is designed to operate in all positions. Ideal for use in boiler tube walls, pressure vessel tanks and other applications where overlay repair is necessary. The overlay system allows for precise control of travel speed which allows the operator to achieve clean consistent weld overlay patterns. The entire system is made up of existing Gullco products and can be easily disassembled into various smaller components for transporting or maneuvering through tighter openings. Gullco’s team of in house engineers can customize the system to meet specific

...more

Model GOV 100 FH - 100 lb Flux Hopper

This 100 lb. Capacity Flux Hopper is designed for mounting either directly above the welding head or on the welding manipulator to maintain the flux in its original dry state. It is complete with mounting lugs, lift-off loading lid, thermometer, flux level window, flux screen and a flux heating system incorporating 40 watts of low density elements. Temperature controlled by thermostat. Temperature range 100º to 400º F. All for operation on 115 volts, 5060 cycle AC power supply. Weight 27 lbs.

...more

KBM-28U Heavy Duty Underside Plate Beveling Machines

Underside Plate Edge Bevelers - Heavy Duty, Portable, Self-Propelled - KBM-28U®produces clean machined bevels with no thermal distortion on mild steel, stainless steel and aluminum plate from 516” (8.0 mm) to 2” (50.0 mm) thick. The KBM-28® bevels the topside of the plate eliminating the need to flip the workpiece…reducing time and cost. Savings are further enhanced when both units are used in applications where both sides of the material require beveling. Adjustable Undercarriage...For Easy Height Adjustment The KBM-28U® units can be purchased with Gullco’s exclusive hydraulic, adjustable height, self-aligning undercarriage assembly for self-propelled beveling along any length of plate maintaining a uniform bevel and consistent root face. Sold separate Hydraulic Adjustable Undercarriage Best suited for applications when frequent height adjustments are required. Adjustable undercarriage supplied with Gullco’s adjustable height self-aligning spring-loaded caster wheel assemblies for self-propelled operation. Best suited for applications where constant machine height is required. Angle Bevel Pins…Enable Bevel Angle Adjustment ...KBM-28U® units are supplied with angle bevel pins for 22 12°, 30°, 37 12°, 45° and 55° bevels. Pins for other bevel angles are available upon request. KBM-28® comes complete with the following standard equipment: 1- KBM-28-X1C Cutter (medium cut) 1- Set Bevel Angle Pins for 22 12°, 30°, 37 12°, 45°and 55 ° 1- Tool Kit

...more

KBM-28 Heavy Duty Plate Beveling Machines

Plate Edge Bevelers, Heavy Duty, Portable, Self-Propelled - KBM-28® produce clean machined bevels with no thermal distortion on mild steel, stainless steel and aluminum plate from 516" (8.0 mm) to 2" (50.0 mm) thick. The KBM-28® bevels the topside of plate reducing time and cost. Savings are further enhanced when the topside Beveler is used with the KBM-28U underside Beveler in applications where both sides of the material require beveling.

...more

KBM-18U Underside Plate Beveling Machine

Gullcos Portable, Underside, Self-Propelled Plate Beveler KBM-18U® produces clean machined bevels with no thermal distortion on mild steel, stainless steel and aluminum plate from 14" (6.0 mm) to 1 12" (38.1 mm) thick. Thinner material can be beveled... consult factory for details. The KBM-18® bevels the topside of the plate eliminating the need to flip the work piece...reducing time and cost. Savings are further enhanced when both units are used in applications where both sides of the material require beveling. Adjustable Undercarriage...For Easy Height Adjustment The KBM-18® can be purchased with a hydraulic adjustable height, self-aligning, spring-loaded caster wheel assembly for self propelled beveling along any length of plate maintaining a uniform bevel and consistent root face.

...more

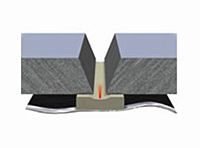

KATBAK Ceramic Weld Backing

As a manufacturer and distributor of ceramics, Gullco can provide you with a KATBAK® ceramic weld backing to meet your needs. If you don't see the ceramic you need in this brochure contact Gullco or your Gullco distributor to discuss your specific requirement.

Features : Impart X-ray Quality Back Beads On Root Pass,Weld One Side Only

...more

KAT Welding and Cutting Automation Carriage - Rigid Track

The Gullco Rigid KAT® welding carriage is used throughout the world to automate a wide variety of welding and cutting operations. It is a rugged, reliable precision welding and cutting travel carriage designed for use on rigid track which enables it to operate along any plane. The rigid track can be used in straight sections or be formed for use on curved surfaces. Gullco manufactures several systems and accessories designed formore

...more

KAT Welding and Cutting Automation Carriage - Rigid Track

The Gullco Rigid KAT® welding carriage is used throughout the world to automate a wide variety of welding and cutting operations. It is a rugged, reliable precision welding and cutting travel carriage designed for use on rigid track which enables it to operate along any plane. The rigid track can be used in straight sections or be formed for use on curved surfaces. Gullco manufactures several systems and accessories designed formore

...more

KAT Welding and Cutting Automation Carriage - Flexible Track

Incorporating Gullcos highly versatile G Type control Reliable automation that improves quality and reduces costs in welding and cutting operations The Gullco Flex KAT® is used throughout the world to automate a wide variety of welding and cutting operations. It is a rugged, reliable precision travel carriage designed for use flexible track which enables it to operate on straight or curved surfaces along any plan Gullco manufactures several systems and accessories designed for use with the Flex KAT®...making it one of the most versatile pieces of weldingcutting automation equipment available. The Gullco Flex KAT® carriage is used throughout the world to automate and improve the quality and efficiency of single or multiple "head" weldingcutting operations. Welding guns or cutting torches mounted on the KAT® carriage move along flexible Gullco "Flex Track" at precisely controlled speeds along the desired path in forward or reverse direction. Gullco's Flex KAT® carriage enables welding guns or cutting torches to operate with precise motion from start to finish regardless of the number of passes or the work pieces involved, improving the quality, efficiency and repeatability of the process. Poor or awkward accessibility, operator fatigue, or inconsistent workmanship are eliminated. This unit is designed for operation on curved surfaces as the flexible track can be positioned to follow the contour of the workpiece. The self-align ing wheel system of the carriage grips the top and bottom of the track, enabling it to travel along any plane. The adjustable wheel assembly keeps the carriage snug to the track, while allowing it to be easily mounted and removed from the track at any point. The positive drive of the KAT® is obtained from a uniquely designed sprocket that engages with slots in the track, driven by a low voltage permanent magnet motor and gear-head power unit assembly.

...more

KAT Welding and Cutting Automation Carriage - Flexible Track

The Gullco Flex KAT® is used throughout the world to automate a wide variety of welding and cutting operations. It is a rugged, reliable precision travel carriage designed for use flexible track which enables it to operate on straight or curved surfaces along any plan Gullcomore

...more

KAT Welding Automation Carriage

The Gullco KAT® which has been used throughout the world for decades has been re-engineered to be smaller and lighter than previous models, yet robust and feature ric

...more

KAT Weld Oscillation Automation Carriage

This advanced oscillation “package" is designed to increase production and improve the quality of the weld produced in automatic mechanized welding operations by minimizing weld defects such as poor penetration, incomplete fusion, overlap and undercut. The GK-200 Series automation ;carriages come with the option for linear or radial oscillation head and can be equipped for use on either rigid or flexible track. The oscillator is available with a linear, pendulum, tangential or step (square pattern) motion to the welding gun with adjustable motorized stroke width, infinitely variable stroke speed adjustment, three independent position dwell times, motorized centre line positioning and automatic wire feed start and travel startstop interface. By combining welding gun oscillation movement with the precision controlled travel speed of the KAT® carriage increased weld quality and consistency can be achieved while reducing the overall production cost of the welding application. Up to 10 weld programs can be produced and stored.

...moreBe first to Rate

Rate This