Vibratory Stress Relieving

As per customers requirement Metric Ton (MOQ)

GURU NANAK STRESS RELIEVERS PVT. LTD.: A. Sole authorized DISTRIBUTOR in India for the 'Formula 62' Vibratory Stress Relief Equipment, manufactured by Stress Relief Engineering, California, USA, and marketed worldwide by Dreyfus Global Trade, LLC, New York, USA B. Offers SERVICES of vibratory stress relieving, anywhere in India, by 'Formula 62' VSR Equipment, USA, for: 1. Heavy Fabrications 2. Fabricated Structures 3. Weld Repaired Jobs 4. Castings 5. Stainless Steel 6. Aluminium 7. Machined components for maintaining dimensional stability 'Formula 62' Vibratory Stress Relief technology is useful in Industries like: 1. Aerospace 2. Automotive 3. Cement 4. Casting 5. Machine Building and Machining 6. Mining 7. Mold making 8. Power Generation 9. Railways 10. Ship Building 11. Sugar 12. Welding and Fabricators Advantages of 'Formula 62' Vibratory Stress Relief Equipment 1. Machine is compact & portable and can be taken to the place of stress relieving needs 2. Process time 15 to 90 minutes, depending on weight of the job 3. Used on wide variety of applications like Fabrications, Machined components, Castings, Shafts, Gears, weld repaired jobs 4. Does not disturb the metallurgical properties like hardness or tensile strength 5. Process is very clean-no discoloration, slag or scale 6. Single job weighing 500 kgs. To 150 tons can be stress relieved 7. Cost of vibratory stress relieving is approx 50% less than that of thermal stress relieving 8. Process is environmentally friendly

...more

Vibratory Stress Relieving Equipment (Model CSP)

One Set(s) (MOQ)

GURU NANAK STRESS RELIEVERS PVT. LTD., are Sole Distributors in India for 'Formula 62' Vibratory Stress Relief Equipment, Model C & Model CSP, manufactured by Stress Relief Engineering, California, USA, and marketed worldwide by Dreyfus Global Trade, LLC, USA. ‘Formula 62’ Equipment, USA, is useful for the vibratory stress relieving of: Heavy Fabrications Fabricated Structures Weld Repaired Jobs Castings Stainless Steel Aluminium Machined components for maintaining dimensional stability 'Formula 62' Vibratory Stress Relieving technology is useful in Industries like: Aerospace Automotive Cement Casting Machine Building and Machining Mining Mold making Power Generation Railways Ship Building Sugar Welding and Fabricators Advantages of 'Formula 62' Vibratory Stress Relieving Equipment Machine is compact & portable and can be taken to the place of stress relieving needs Process time 15 to 90 minutes, depending on weight of the job Used on wide variety of applications – Fabrications, Machined components, Castings, Shafts, Gears, weld repaired jobs Does not disturb the metallurgical properties like hardness or tensile strength Process is very clean – no discoloration, slag or scale Single job weighing 500 kgs. to 150 tons can be stress relieved

...more

Vibratory Stress Relieving Equipment (Model C)

One Set(s) (MOQ)

GURU NANAK STRESS RELIEVERS PVT. LTD., are Sole Distributors in India for 'Formula 62' Vibratory Stress Relief Equipment, Model C & Model CSP, manufactured by Stress Relief Engineering, California, USA, and marketed worldwide by Dreyfus Global Trade, LLC, USA. ‘Formula 62’ Equipment, USA, is useful for the vibratory stress relieving of: Heavy Fabrications Fabricated Structures Weld Repaired Jobs Castings Stainless Steel Aluminium Machined components for maintaining dimensional stability 'Formula 62' Vibratory Stress Relieving technology is useful in Industries like: Aerospace Automotive Cement Casting Machine Building and Machining Mining Mold making Power Generation Railways Ship Building Sugar Welding and Fabricators Advantages of 'Formula 62' Vibratory Stress Relieving Equipment Machine is compact & portable and can be taken to the place of stress relieving needs Process time 15 to 90 minutes, depending on weight of the job Used on wide variety of applications – Fabrications, Machined components, Castings, Shafts, Gears, weld repaired jobs Does not disturb the metallurgical properties like hardness or tensile strength Process is very clean – no discoloration, slag or scale Single job weighing 500 kgs. to 150 tons can be stress relieved

...more

Vibratory Stress Relief Equipment (Model CSP)

formula 62 - model csp units are designed to provide years of continuous service even under the adverse conditions found in the factory or the field. each unit contains all the items necessary for operating and controlling the stress relief of weldments and machined components. the uni-body construction of the cabinet is functional as well as durable. ample storage space is provided below the console to house the heavy duty vibrator and accessories. the interior electronics section is sealed off from outside sources of contamination such as oil mistr, dirt or abrasive grit. the machine is portable and can be used on any 220230 volt,50 hz, single phase power source at 100% duty cycle. features heavy duty vibrator unit with attachment platecastersa.c. supply cordaccessory kit containing accelerometer, accelerometer clamp and coaxial cablesinstruction manual containing: operating instructions, engineering information, maintenance manual, parts catalog, diagrams and trouble shooting guideunit comes with a written 3 year warranty technical specifications modes of operation: (3) manual, manual resonantnon-resonant, automaticvariable frequency controlanalog resonance metermanual time indicatorresettable circuit breaker protectioncabinet size (inches) 16d x 26l x 33h (cm) 40.6d x 66l x 84happrox. shipping wt. 168 lbs. (76 kgs.)voltage options: 200, 210, 220, 230, 5060 hz., 1 phase

...more

Vibratory Stress Relief Equipment (Model C)

formula 62 – model c units are designed to provide years of continuous service even under the adverse conditions found in the factory or the field. each unit contains all the items necessary for operating, controlling, and recording the stress relief of weldments and machined components. the uni-body construction of the cabinet is functional as well as durable. ample storage space is provided to house the heavy duty vibrator and accessories. the interior electronics section is sealed off from outside sources of contamination such as oil mist vapor, dirt or abrasive grit. the machine is portable and can be used on any 220230 volt*, 50 hz., single phase power source at 100% duty cycle. features heavy duty vibrator unit with attachment platecastersa.c. supply cordaccessory kit containing accelerometer, accelerometer clamp and coaxial cablesinstruction manual containing : operating instructions, engineering information, maintenance manual, parts catalog, diagrams and trouble shooting guideunit comes with a written 3 year warranty technical specifications modes of operation : (3) manual, manual resonantnon-resonant, automaticstrip chart recordervariable frequency controlanalog resonance metermanual time indicatorresettable circuit breaker protectioncabinet size (inches) 16d x 26l x 33h (cm) 40.6d x 66l x 84happrox. shipping wt. 168 lbs. (76 kgs.)voltage options: 200, 210, 220, 230, 5060 hz., 1 phase

...more

Stress relieving of welded mould

As per customers requirement Metric Ton (MOQ)

GURU NANAK STRESS RELIEVERS PVT. LTD.: A. Sole authorized DISTRIBUTOR in India for the 'Formula 62' Vibratory Stress Relief Equipment, manufactured by Stress Relief Engineering, California, USA, and marketed worldwide by Dreyfus Global Trade, LLC, New York, USA B. Offers SERVICES of vibratory stress relieving, anywhere in India, by Formula 62 VSR Equipment, USA, for: 1. Heavy Fabrications 2. Fabricated Structures 3. Weld Repaired Jobs 4. Castings 5. Stainless Steel 6. Aluminium 7. Machined components for maintaining dimensional stability 'Formula 62' Vibratory Stress Relief technology is useful in Industries like: 1. Aerospace 2. Automotive 3. Cement 4. Casting 5. Machine Building and Machining 6. Mining 7. Mold making 8. Power Generation 9. Railways 10. Ship Building 11. Sugar 12. Welding and Fabricators Advantages of 'Formula 62' Vibratory Stress Relief Equipment 1. Machine is compact & portable and can be taken to the place of stress relieving needs 2. Process time 15 to 90 minutes, depending on weight of the job 3. Used on wide variety of applications like Fabrications, Machined components, Castings, Shafts, Gears, weld repaired jobs 4. Does not disturb the metallurgical properties like hardness or tensile strength 5. Process is very clean-no discoloration, slag or scale 6. Single job weighing 500 kgs. To 150 tons can be stress relieved 7. Cost of vibratory stress relieving is approx 50% less than that of thermal stress relieving 8. Process is environmentally friendly

...more

Stress relieving of stainless steel

As per customers requirement Metric Ton (MOQ)

GURU NANAK STRESS RELIEVERS PVT. LTD.: A. Sole authorized DISTRIBUTOR in India for the 'Formula 62' Vibratory Stress Relief Equipment, manufactured by Stress Relief Engineering, California, USA, and marketed worldwide by Dreyfus Global Trade, LLC, New York, USA B. Offers SERVICES of vibratory stress relieving, anywhere in India, by Formula 62 VSR Equipment, USA, for: 1. Heavy Fabrications 2. Fabricated Structures 3. Weld Repaired Jobs 4. Castings 5. Stainless Steel 6. Aluminium 7. Machined components for maintaining dimensional stability 'Formula 62' Vibratory Stress Relief technology is useful in Industries like: 1. Aerospace 2. Automotive 3. Cement 4. Casting 5. Machine Building and Machining 6. Mining 7. Mold making 8. Power Generation 9. Railways 10. Ship Building 11. Sugar 12. Welding and Fabricators Advantages of 'Formula 62' Vibratory Stress Relief Equipment 1. Machine is compact & portable and can be taken to the place of stress relieving needs 2. Process time 15 to 90 minutes, depending on weight of the job 3. Used on wide variety of applications like Fabrications, Machined components, Castings, Shafts, Gears, weld repaired jobs 4. Does not disturb the metallurgical properties like hardness or tensile strength 5. Process is very clean - no discoloration, slag or scale 6. Single job weighing 500 kgs. To 150 tons can be stress relieved 7. Cost of vibratory stress relieving is approx 50% less than that of thermal stress relieving 8. Process is environmentally friendly

...more

Stress relieving of machine component for mining industry

As per customers requirement Metric Ton (MOQ)

GURU NANAK STRESS RELIEVERS PVT. LTD.: A. sole authorized DISTRIBUTOR in India for the 'Formula 62' Vibratory Stress Relief Equipment, manufactured by Stress Relief Engineering, California, USA, and marketed worldwide by Dreyfus Global Trade, LLC, New York, USA B. Offers SERVICES of vibratory stress relieving, anywhere in India, by Formula 62 VSR Equipment, USA, for: 1. Heavy Fabrications 2. Fabricated Structures 3. Weld Repaired Jobs 4. Castings 5. Stainless Steel 6. Aluminium 7. Machined components for maintaining dimensional stability 'Formula 62' Vibratory Stress Relief technology is useful in Industries like: 1. Aerospace 2. Automotive 3. Cement 4. Casting 5. Machine Building and Machining 6. Mining 7. Mold making 8. Power Generation 9. Railways 10. Ship Building 11. Sugar 12. Welding and Fabricators Advantages of 'Formula 62' Vibratory Stress Relief Equipment 1. Machine is compact & portable and can be taken to the place of stress relieving needs 2. Process time 15 to 90 minutes, depending on weight of the job 3. Used on wide variety of applications like Fabrications, Machined components, Castings, Shafts, Gears, weld repaired jobs 4. Does not disturb the metallurgical properties like hardness or tensile strength 5. Process is very clean-no discoloration, slag or scale 6. Single job weighing 500 kgs. To 150 tons can be stress relieved 7. Cost of vibratory stress relieving is approx 50% less than that of thermal stress relieving 8. Process is environmentally friendly

...more

'Formula 62' Vibratory Stress Relief Machine, Model C & CSP

2,800,000 - 3,500,000 Per No

01 Piece (MOQ)

GURU NANAK STRESS RELIEVERS PVT. LTD.: a. Sole Authorized DISTRIBUTOR in India for the 'Formula 62' Vibratory Stress Relief Equipment, manufactured by Stress Relief Engineering, California, USA, and marketed worldwide by Dreyfus Global Trade, LLC, New York, USA B. Formula 62 VSR Equipment, USA, applicable for the stress relieving in: 1. Heavy Fabrications 2. Fabricated Structures 3. Weld Repaired Jobs 4. Castings 5. Stainless Steel 6. Aluminium 7. Machined components for maintaining dimensional stability 'Formula 62' Vibratory Stress Relief technology is useful in industries like: 1. Aerospace 2. Automotive 3. Cement 4. Casting 5. Machine Building and Machining 6. Mining 7. Mold Making 8. Power Generation 9. Railways 10. Ship Building 11. Sugar 12. Welding and Fabricators Advantages of 'Formula 62' Vibratory Stress Relief Equipment 1. Machine is compact & portable and can be taken to the place of stress relieving needs 2. Process time 15 to 90 minutes, depending on weight of the job 3. Used on wide variety of applications like fabrications, machined components, castings, shafts, gears, weld repaired jobs 4. Does not disturb the metallurgical properties like hardness or tensile strength 5. Process is very clean-no discoloration, slag or scale 6. Single job weighing 500 kgs. To 150 tons can be stress relieved 7. Cost of vibratory stress relieving is approx 50% less than that of thermal stress relieving 8. Process is environmentally friendly

Country of Origin : USA

Certification : CE Certified

Application : Reduce The Internal Stresses

Voltage : 220V

Condition : New

Power : 1-3kw

Driven Type : Electricity

Warranty : 3yrs

Automation Grade : Automatic, Manual

Type : Stress Relieving Equipment

...more

Stress relieving of forged steel

As per customers requirement Metric Ton (MOQ)

GURU NANAK STRESS RELIEVERS PVT. LTD.: A. Sole authorized DISTRIBUTOR in India for the 'Formula 62' Vibratory Stress Relief Equipment, manufactured by Stress Relief Engineering, California, USA, and marketed worldwide by Dreyfus Global Trade, LLC, New York, USA B. Offers SERVICES of vibratory stress relieving, anywhere in India, by Formula 62 VSR Equipment, USA, for: 1. Heavy Fabrications 2. Fabricated Structures 3. Weld Repaired Jobs 4. Castings 5. Stainless Steel 6. Aluminium 7. Machined components for maintaining dimensional stability 'Formula 62' Vibratory Stress Relief technology is useful in Industries like: 1. Aerospace 2. Automotive 3. Cement 4. Casting 5. Machine Building and Machining 6. Mining 7. Mold making 8. Power Generation 9. Railways 10. Ship Building 11. Sugar 12. Welding and Fabricators Advantages of 'Formula 62' Vibratory Stress Relief Equipment 1. Machine is compact & portable and can be taken to the place of stress relieving needs 2. Process time 15 to 90 minutes, depending on weight of the job 3. Used on wide variety of applications like Fabrications, Machined components, Castings, Shafts, Gears, weld repaired jobs 4. Does not disturb the metallurgical properties like hardness or tensile strength 5. Process is very clean-discoloration, slag or scale 6. Single job weighing 500 kgs. To 150 tons can be stress relieved 7. Cost of vibratory stress relieving is approx 50% less than that of thermal stress relieving 8. Process is environmentally friendly

...more

Stress relieving of cylindrical jobs

As per customers requirement Metric Ton (MOQ)

GURU NANAK STRESS RELIEVERS PVT. LTD.: A. Sole authorized DISTRIBUTOR in India for the 'Formula 62' Vibratory Stress Relief Equipment, manufactured by Stress Relief Engineering, California, USA, and marketed worldwide by Dreyfus Global Trade, LLC, New York, USA B. Offers SERVICES of vibratory stress relieving, anywhere in India, by 'Formula 62' VSR Equipment, USA, for: 1. Heavy Fabrications 2. Fabricated Structures 3. Weld Repaired Jobs 4. Castings 5. Stainless Steel 6. Aluminium 7. Machined components for maintaining dimensional stability 'Formula 62' Vibratory Stress Relief technology is useful in Industries like: 1. Aerospace 2. Automotive 3. Cement 4. Casting 5. Machine Building and Machining 6. Mining 7. Mold making 8. Power Generation 9. Railways 10. Ship Building 11. Sugar 12. Welding and Fabricators Advantages of 'Formula 62' Vibratory Stress Relief Equipment 1. Machine is compact & portable and can be taken to the place of stress relieving needs 2. Process time 15 to 90 minutes, depending on weight of the job 3. Used on wide variety of applications - Fabrications, Machined components, Castings, Shafts, Gears, weld repaired jobs 4. Does not disturb the metallurgical properties like hardness or tensile strength 5. Process is very clean - no discoloration, slag or scale 6. Single job weighing 500 kgs. To 150 tons can be stress relieved 7. Cost of vibratory stress relieving is approx 50% less than that of thermal stress relieving 8. Process is environmentally friendly

...more

Stress relieving of castings

As per customers requirement Metric Ton (MOQ)

GURU NANAK STRESS RELIEVERS PVT. LTD.: A. Sole Authorized DISTRIBUTOR in India for the 'Formula 62' Vibratory Stress Relief Equipment, manufactured by Stress Relief Engineering, California, USA, and marketed worldwide by Dreyfus Global Trade, LLC, New York, USA B. Offers SERVICES of vibratory stress relieving, anywhere in India, by Formula 62 VSR Equipment, USA, for: 1. Heavy Fabrications 2. Fabricated Structures 3. Weld Repaired Jobs 4. Castings 5. Stainless Steel 6. Aluminium 7. Machined components for maintaining dimensional stability 'Formula 62' Vibratory Stress Relief technology is useful in Industries like: 1. Aerospace 2. Automotive 3. Cement 4. Casting 5. Machine Building and Machining 6. Mining 7. Mold making 8. Power Generation 9. Railways 10. Ship Building 11. Sugar 12. Welding and Fabricators Advantages of 'Formula 62' Vibratory Stress Relief Equipment 1. Machine is compact & portable and can be taken to the place of stress relieving needs 2. Process time 15 to 90 minutes, depending on weight of the job 3. Used on wide variety of applications like Fabrications, Machined components, Castings, Shafts, Gears, weld repaired jobs 4. Does not disturb the metallurgical properties like hardness or tensile strength 5. Process is very clean-no discoloration, slag or scale 6. Single job weighing 500 kgs. To 150 tons can be stress relieved 7. Cost of vibratory stress relieving is approx 50% less than that of thermal stress relieving 8. Process is environmentally friendly

...more

aluminium stress relieving equipment

3,500 - 75,000 Per Piece

A. Sole authorized DISTRIBUTOR in India for the 'Formula 62' Vibratory Stress Relief Equipment, manufactured by Stress Relief Engineering, California, USA, and marketed worldwide by Dreyfus Global Trade, LLC, New York, USA B. Offers SERVICES of vibratory stress relieving, anywhere in India, by �Formula 62� Equipment, USA, for: 1. Heavy Fabrications 2. Fabricated Structures 3. Weld Repaired Jobs 4. Castings 5. Stainless Steel 6. Aluminium 7. Machined components for maintaining dimensional stability 'Formula 62' Vibratory Stress Relief technology is useful in Industries like: 1. Aerospace 2. Automotive 3. Cement 4. Casting 5. Machine Building and Machining 6. Mining 7. Mold making 8. Power Generation 9. Railways 10. Ship Building 11. Sugar 12. Welding and Fabricators Advantages of 'Formula 62' Vibratory Stress Relief Equipment 1. Machine is compact & portable and can be taken to the place of stress relieving needs 2. Process time 15 to 90 minutes, depending on weight of the job 3. Used on wide variety of applications like Fabrications, Machined components, Castings, Shafts, Gears, weld repaired jobs 4. Does not disturb the metallurgical properties like hardness or tensile strength 5. Process is very clean - no discoloration, slag or scale 6. Single job weighing 500 kgs. To 150 tons can be stress relieved 7. Cost of vibratory stress relieving is approx 50% less than that of thermal stress relieving 8. Process is environmentally friendly

...more

Stress relieving for fabricated structure

As per customers requirement Metric Ton (MOQ)

GURU NANAK STRESS RELIEVERS PVT. LTD.: a. Sole Authorized DISTRIBUTOR in india for the 'Formula 62' Vibratory Stress Relief Equipment, manufactured by Stress Relief Engineering, California, USA, and marketed worldwide by Dreyfus Global Trade, LLC, New York, USA b. Offers SERVICES of vibratory stress relieving, anywhere in India, by Formula 62 VSR Equipment, USA, for: 1. Heavy Fabrications 2. Fabricated Structures 3. Weld Repaired Jobs 4. Castings 5. Stainless Steel 6. Aluminium 7. Machined components for maintaining dimensional stability 'Formula 62' Vibratory Stress Relief technology is useful in industries like: 1. Aerospace 2. Automotive 3. Cement 4. Casting 5. Machine Building and Machining 6. Mining 7. Mold Making 8. Power Generation 9. Railways 10. Ship Building 11. Sugar 12. Welding and Fabricators Advantages of 'Formula 62' Vibratory Vtress Relief Equipment 1. Machine is compact & portable and can be taken to the place of stress relieving needs 2. Process time 15 to 90 minutes, depending on weight of the job 3. Used on wide variety of applications like fabrications, machined components, castings, shafts, gears, weld repaired jobs 4. Does not disturb the metallurgical properties like hardness or tensile strength 5. Process is very clean-no discoloration, slag or scale 6. Single job weighing 500 kgs. To 150 tons can be stress relieved 7. Cost of vibratory stress relieving is approx 50% less than that of thermal stress relieving 8 Process is environmentally friendly

...more

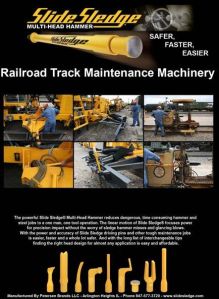

Slide Sledge Multi Head Hammer for Railway application

One Set(s) (MOQ)

GURU NANAK STRESS RELIEVERS PVT. LTD.: Authorized Distributor in India for Slide Sledge Multi-Head Hammer, Petersen Brands, USA Servicing of heavy equipment / machines need extreme impact tools to 1. drive pin rolls 2. insert / replace bushings 3. change worn out items 4. shear rusted bolts Normally above done by two persons � one holding tool & other swings large sledge hammer. This could result in 1. injuries / smashed thumb 2. flying steel shrapnel Slide Sledge, Petersen Brands, USA, is a better way which uses 1. one person 2. one tool operator 3. maximum impact with precision & control 4. over 20 applications specific tips � for fast work Slide Sledge has Advantages of 1. safety 2. less injuries 3. less man-hours 4. more productivity 5. more profitability Application of Slide Sledge in heavy machinery / equipment used in 1. Mining 2. Railroads / Railway Workshops 3. Military � Heavy Vehicles / Machinery used for Construction, Transportation, Tracked 4. Infrastructure 5. Cement & Fertilizer 6. Ship Building & Aero 7. Sugar Factories & Agriculture Benefits: 1. Increases profitability by: � Eliminating special equipment or extra operator by using task specific tips � one man operation � down time reduced to minimum 2. Simplifies field maintenance / repairs: � Remove & install pin on any type of field equipment � Cut & shear rusted bolts in seconds � Reach between bucket teeth for easy removal & installation � Adapt to separator forks for fast & easy change outs 3. Promotes a safer working: � Minimizes operator effort, injury & muscle starin � Eliminates flying debris associated with hammer & chisel 4. Adapts to numerous applications � With interchangeable application specific tips - allows one tool to do job of many � Quick change of tips 5. Delivers powerful & precise impact � Delivers maximum (18,000 psi) impact force � Can use additional 5 lbs hammer weight for additional impact force

Brand Name : Petersen Brands, USA

...more

Slide Sledge (Multi Head Hammer), Petersen Brands, USA

One Set(s) (MOQ)

GURU NANAK STRESS RELIEVERS PVT. LTD.: Authorized Distributor in India for Slide Sledge Multi-Head Hammer, Petersen Brands, USA Servicing of heavy equipment / machines need extreme impact tools to 1. drive pin rolls 2. insert / replace bushings 3. change worn out items 4. shear rusted bolts Normally above done by two persons � one holding tool & other swings large sledge hammer. This could result in 1. injuries / smashed thumb 2. flying steel shrapnel Slide Sledge, Petersen Brands, USA, is a better way which uses 1. one person 2. one tool operator 3. maximum impact with precision & control 4. over 20 applications specific tips � for fast work Slide Sledge has Advantages of 1. safety 2. less injuries 3. less man-hours 4. more productivity 5. more profitability Application of Slide Sledge in heavy machinery / equipment used in 1. Mining 2. Railroads / Railway Workshops 3. Military � Heavy Vehicles / Machinery used for Construction, Transportation, Tracked 4. Infrastructure 5. Cement & Fertilizer 6. Ship Building & Aero 7. Sugar Factories & Agriculture Benefits: 1. Increases profitability by: � Eliminating special equipment or extra operator by using task specific tips � one man operation � down time reduced to minimum 2. Simplifies field maintenance / repairs: � Remove & install pin on any type of field equipment � Cut & shear rusted bolts in seconds � Reach between bucket teeth for easy removal & installation � Adapt to separator forks for fast & easy change outs 3. Promotes a safer working: � Minimizes operator effort, injury & muscle starin � Eliminates flying debris associated with hammer & chisel 4. Adapts to numerous applications � With interchangeable application specific tips - allows one tool to do job of many � Quick change of tips 5. Delivers powerful & precise impact � Delivers maximum (18,000 psi) impact force � Can use additional 5 lbs hammer weight for additional impact force

...more

Slide Sledge Multi Head Hammer for Municipalities

One Set(s) (MOQ)

GURU NANAK STRESS RELIEVERS PVT. LTD.: Authorized Distributor in India for Slide Sledge Multi-Head Hammer, Petersen Brands, USA Servicing of heavy equipment / machines need extreme impact tools to 1. drive pin rolls 2. insert / replace bushings 3. change worn out items 4. shear rusted bolts Normally above done by two persons � one holding tool & other swings large sledge hammer. This could result in 1. injuries / smashed thumb 2. flying steel shrapnel Slide Sledge, Petersen Brands, USA, is a better way which uses 1. one person 2. one tool operator 3. maximum impact with precision & control 4. over 20 applications specific tips � for fast work Slide Sledge has Advantages of 1. safety 2. less injuries 3. less man-hours 4. more productivity 5. more profitability Application of Slide Sledge in heavy machinery / equipment used in 1. Mining 2. Railroads / Railway Workshops 3. Military � Heavy Vehicles / Machinery used for Construction, Transportation, Tracked 4. Infrastructure 5. Cement & Fertilizer 6. Ship Building & Aero 7. Sugar Factories & Agriculture Benefits: 1. Increases profitability by: � Eliminating special equipment or extra operator by using task specific tips � one man operation � down time reduced to minimum 2. Simplifies field maintenance / repairs: � Remove & install pin on any type of field equipment � Cut & shear rusted bolts in seconds � Reach between bucket teeth for easy removal & installation � Adapt to separator forks for fast & easy change outs 3. Promotes a safer working: � Minimizes operator effort, injury & muscle starin � Eliminates flying debris associated with hammer & chisel 4. Adapts to numerous applications � With interchangeable application specific tips - allows one tool to do job of many � Quick change of tips 5. Delivers powerful & precise impact � Delivers maximum (18,000 psi) impact force � Can use additional 5 lbs hammer weight for additional impact force

...more

Slide Sledge Multi Head Hammer for Mining Application

One Set(s) (MOQ)

GURU NANAK STRESS RELIEVERS PVT. LTD.: Authorized Distributor in India for Slide Sledge Multi-Head Hammer, Petersen Brands, USA Servicing of heavy equipment / machines need extreme impact tools to 1. drive pin rolls 2. insert / replace bushings 3. change worn out items 4. shear rusted bolts Normally above done by two persons � one holding tool & other swings large sledge hammer. This could result in 1. injuries / smashed thumb 2. flying steel shrapnel Slide Sledge, Petersen Brands, USA, is a better way which uses 1. one person 2. one tool operator 3. maximum impact with precision & control 4. over 20 applications specific tips � for fast work Slide Sledge has Advantages of 1. safety 2. less injuries 3. less man-hours 4. more productivity 5. more profitability Application of Slide Sledge in heavy machinery / equipment used in 1. Mining 2. Railroads / Railway Workshops 3. Military � Heavy Vehicles / Machinery used for Construction, Transportation, Tracked 4. Infrastructure 5. Cement & Fertilizer 6. Ship Building & Aero 7. Sugar Factories & Agriculture Benefits: 1. Increases profitability by: � Eliminating special equipment or extra operator by using task specific tips � one man operation � down time reduced to minimum 2. Simplifies field maintenance / repairs: � Remove & install pin on any type of field equipment � Cut & shear rusted bolts in seconds � Reach between bucket teeth for easy removal & installation � Adapt to separator forks for fast & easy change outs 3. Promotes a safer working: � Minimizes operator effort, injury & muscle starin � Eliminates flying debris associated with hammer & chisel 4. Adapts to numerous applications � With interchangeable application specific tips - allows one tool to do job of many � Quick change of tips 5. Delivers powerful & precise impact � Delivers maximum (18,000 psi) impact force � Can use additional 5 lbs hammer weight for additional impact force

Brand Name : Petersen Brands, USA

...more

Slide Sledge Multi Head Hammer for Defense Application

One Set(s) (MOQ)

GURU NANAK STRESS RELIEVERS PVT. LTD.: Authorized Distributor in India for Slide Sledge Multi-Head Hammer, Petersen Brands, USA Servicing of heavy equipment / machines need extreme impact tools to 1. drive pin rolls 2. insert / replace bushings 3. change worn out items 4. shear rusted bolts Normally above done by two persons � one holding tool & other swings large sledge hammer. This could result in 1. injuries / smashed thumb 2. flying steel shrapnel Slide Sledge, Petersen Brands, USA, is a better way which uses 1. one person 2. one tool operator 3. maximum impact with precision & control 4. over 20 applications specific tips � for fast work Slide Sledge has Advantages of 1. safety 2. less injuries 3. less man-hours 4. more productivity 5. more profitability Application of Slide Sledge in heavy machinery / equipment used in 1. Mining 2. Railroads / Railway Workshops 3. Military � Heavy Vehicles / Machinery used for Construction, Transportation, Tracked 4. Infrastructure 5. Cement & Fertilizer 6. Ship Building & Aero 7. Sugar Factories & Agriculture Benefits: 1. Increases profitability by: � Eliminating special equipment or extra operator by using task specific tips � one man operation � down time reduced to minimum 2. Simplifies field maintenance / repairs: � Remove & install pin on any type of field equipment � Cut & shear rusted bolts in seconds � Reach between bucket teeth for easy removal & installation � Adapt to separator forks for fast & easy change outs 3. Promotes a safer working: � Minimizes operator effort, injury & muscle starin � Eliminates flying debris associated with hammer & chisel 4. Adapts to numerous applications � With interchangeable application specific tips - allows one tool to do job of many � Quick change of tips 5. Delivers powerful & precise impact � Delivers maximum (18,000 psi) impact force � Can use additional 5 lbs hammer weight for additional impact force

Brand Name : Petersen Brands, USA

...more

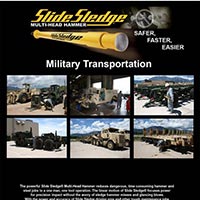

Slide Sledge Multi Head Hammer for Military Transportation

One Set(s) (MOQ)

GURU NANAK STRESS RELIEVERS PVT. LTD.: Authorized Distributor in India for Slide Sledge Multi-Head Hammer, Petersen Brands, USA Servicing of heavy equipment / machines need extreme impact tools to 1. drive pin rolls 2. insert / replace bushings 3. change worn out items 4. shear rusted bolts Normally above done by two persons � one holding tool & other swings large sledge hammer. This could result in 1. injuries / smashed thumb 2. flying steel shrapnel Slide Sledge, Petersen Brands, USA, is a better way which uses 1. one person 2. one tool operator 3. maximum impact with precision & control 4. over 20 applications specific tips � for fast work Slide Sledge has Advantages of 1. safety 2. less injuries 3. less man-hours 4. more productivity 5. more profitability Application of Slide Sledge in heavy machinery / equipment used in 1. Mining 2. Railroads / Railway Workshops 3. Military � Heavy Vehicles / Machinery used for Construction, Transportation, Tracked 4. Infrastructure 5. Cement & Fertilizer 6. Ship Building & Aero 7. Sugar Factories & Agriculture Benefits: 1. Increases profitability by: � Eliminating special equipment or extra operator by using task specific tips � one man operation � down time reduced to minimum 2. Simplifies field maintenance / repairs: � Remove & install pin on any type of field equipment � Cut & shear rusted bolts in seconds � Reach between bucket teeth for easy removal & installation � Adapt to separator forks for fast & easy change outs 3. Promotes a safer working: � Minimizes operator effort, injury & muscle starin � Eliminates flying debris associated with hammer & chisel 4. Adapts to numerous applications � With interchangeable application specific tips - allows one tool to do job of many � Quick change of tips 5. Delivers powerful & precise impact � Delivers maximum (18,000 psi) impact force � Can use additional 5 lbs hammer weight for additional impact force

...more

Slide Sledge Multi Head Hammer for Military Application

One Piece (MOQ)

GURU NANAK STRESS RELIEVERS PVT. LTD.: Authorized Distributor in India for Slide Sledge Multi-Head Hammer, Petersen Brands, USA Servicing of heavy equipment / machines need extreme impact tools to 1. drive pin rolls 2. insert / replace bushings 3. change worn out items 4. shear rusted bolts Normally above done by two persons � one holding tool & other swings large sledge hammer. This could result in 1. injuries / smashed thumb 2. flying steel shrapnel Slide Sledge, Petersen Brands, USA, is a better way which uses 1. one person 2. one tool operator 3. maximum impact with precision & control 4. over 20 applications specific tips � for fast work Slide Sledge has Advantages of 1. safety 2. less injuries 3. less man-hours 4. more productivity 5. more profitability Application of Slide Sledge in heavy machinery / equipment used in 1. Mining 2. Railroads / Railway Workshops 3. Military � Heavy Vehicles / Machinery used for Construction, Transportation, Tracked 4. Infrastructure 5. Cement & Fertilizer 6. Ship Building & Aero 7. Sugar Factories & Agriculture Benefits: 1. Increases profitability by: � Eliminating special equipment or extra operator by using task specific tips � one man operation � down time reduced to minimum 2. Simplifies field maintenance / repairs: � Remove & install pin on any type of field equipment � Cut & shear rusted bolts in seconds � Reach between bucket teeth for easy removal & installation � Adapt to separator forks for fast & easy change outs 3. Promotes a safer working: � Minimizes operator effort, injury & muscle starin � Eliminates flying debris associated with hammer & chisel 4. Adapts to numerous applications � With interchangeable application specific tips - allows one tool to do job of many � Quick change of tips 5. Delivers powerful & precise impact � Delivers maximum (18,000 psi) impact force � Can use additional 5 lbs hammer weight for additional impact force

...more

Slide Sledge Multi-Head Hammer (Petersen Patented Brand)

Guru nanak stress relievers pvt. Ltd.: authorized distributor in india for slide sledge multi-head hammer, petersen brands, usa servicing of heavy equipment machines need extreme impact tools to 1. drive pin rolls 2. insert replace bushings 3. change worn out items 4. shear rusted bolts normally above done by two persons – one holding tool & other swings large sledge hammer. This could result in 1. injuries smashed thumb 2. flying steel shrapnel slide sledge, petersen brands, usa, is a better way which uses 1. one person 2. one tool operator 3. maximum impact with precision & control 4. over 20 applications specific tips – for fast work slide sledge has advantages of 1. safety 2. less injuries 3. less man-hours 4. more productivity 5. more profitability application of slide sledge in heavy machinery equipment used in 1. mining 2. railroads railway workshops 3. military – heavy vehicles machinery used for construction, transportation, tracked 4. infrastructure 5. cement & fertilizer 6. ship building & aero 7. sugar factories & agriculture benefits: 1. increases profitability by: • eliminating special equipment or extra operator by using task specific tips • one man operation • down time reduced to minimum 2. simplifies field maintenance repairs: • remove & install pin on any type of field equipment • cut & shear rusted bolts in seconds • reach between bucket teeth for easy removal & installation • adapt to separator forks for fast & easy change outs 3. promotes a safer working: • minimizes operator effort, injury & muscle starin • eliminates flying debris associated with hammer & chisel 4. adapts to numerous applications • with interchangeable application specific tips - allows one tool to do job of many • quick change of tips 5. delivers powerful & precise impact • delivers maximum (18,000 psi) impact force • can use additional 5 lbs hammer weight for additional impact force

...more

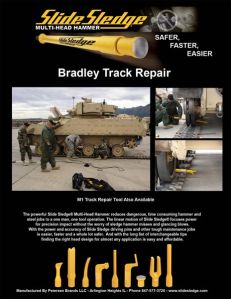

Slide Sledge Multi Head Hammer for Bradley Track Repair

One Set(s) (MOQ)

GURU NANAK STRESS RELIEVERS PVT. LTD.: Authorized Distributor in India for Slide Sledge Multi-Head Hammer, Petersen Brands, USA Servicing of heavy equipment / machines need extreme impact tools to 1. drive pin rolls 2. insert / replace bushings 3. change worn out items 4. shear rusted bolts Normally above done by two persons � one holding tool & other swings large sledge hammer. This could result in 1. injuries / smashed thumb 2. flying steel shrapnel Slide Sledge, Petersen Brands, USA, is a better way which uses 1. one person 2. one tool operator 3. maximum impact with precision & control 4. over 20 applications specific tips � for fast work Slide Sledge has Advantages of 1. safety 2. less injuries 3. less man-hours 4. more productivity 5. more profitability Application of Slide Sledge in heavy machinery / equipment used in 1. Mining 2. Railroads / Railway Workshops 3. Military � Heavy Vehicles / Machinery used for Construction, Transportation, Tracked 4. Infrastructure 5. Cement & Fertilizer 6. Ship Building & Aero 7. Sugar Factories & Agriculture Benefits: 1. Increases profitability by: � Eliminating special equipment or extra operator by using task specific tips � one man operation � down time reduced to minimum 2. Simplifies field maintenance / repairs: � Remove & install pin on any type of field equipment � Cut & shear rusted bolts in seconds � Reach between bucket teeth for easy removal & installation � Adapt to separator forks for fast & easy change outs 3. Promotes a safer working: � Minimizes operator effort, injury & muscle starin � Eliminates flying debris associated with hammer & chisel 4. Adapts to numerous applications � With interchangeable application specific tips - allows one tool to do job of many � Quick change of tips 5. Delivers powerful & precise impact � Delivers maximum (18,000 psi) impact force � Can use additional 5 lbs hammer weight for additional impact force

...more

Slide Sledge Multi-Head Hammer

One Set(s) (MOQ)

Guru Nanak Stress Relievers Pvt. Ltd. is a prominent distributor of Slide Sledge Multi-Head Hammer. We specialize in offering Slide Sledge (Multi Head Hammer). The Slide Sledge (Multi Head Hammer), we offer, is manufactured by Petersen Brands LLC, Illinois, USA. SLIDE SLEDGE for the heavy machinery/ equipment associated with : Military Mining Railways Infrastructure Defense Additional Applications for Bradley Track Repair Military Maintenance Military Transportation Municipalities Railroad Track Maintenance Skid Steerer and Scissor Lifts Mining Construction, Infrastructure, Tracked Vehicles Servicing of heavy equipment & machines need extreme impact tools to : Drive pin rolls Insert or replace bushings Change worn out items Shear rusted bolts all this, plus more, with least down time Normally, this is done by two persons ½ ½ one holding tool and other swings large sledge hammer. This could result in : Injuries, maybe smashed thumb Flying steel shrapnel Slide Sledge (patented), Petersen Brands, USA, is a better way which uses : One person One tool operator Maximum impact with precision & control Over 20 applications specific tips â�� can be attached to the end of tool for fast work Advantages Safety Less injuries, so Less workmenâ��s compensation claims Less man-hours required, so More productivity More profitability Reduced downtime Benefits Increases profitability by Eliminating special equipment or additional operator by using task specific tips One man operation Down time hours reduced to minimum Simplifies field maintenance / repairs : Remove & install pin on any type of field equipment / vehicle / machinery Cuts & shears rusted bolts in seconds Reaches between bucket teeth for easy removal & installation Adapts to separator forks for fast & easy change outs Promotes a safer work environment : Minimizes operator effort & risk of injury Reduces muscle strain Diminishes flying debris associated with hammer and chisel Adapts to numerous applications Accommodates interchangeable application specific tips that allows one tool to do job of many Adapts to quick change of tips Delivers powerful & precise impact Constructed of induction hardened steel for long life Delivers maximum (18,000 psi) impact force Can use additional 5 lbs hammer weight for additional impact force Adapts to quick change of tips Delivers powerful & precise impact Constructed of induction hardened steel for long life Delivers maximum (18,000 psi) impact force Can use an additional 5 lbs hammer weight for additional impact force

Weight : 1-2Ton, 100-200kg, 200-300kg, 300-400kg, 900kg-1Ton

Condition : New

Finishing : Polished

Warranty : 1Yrs

...more

Vibratory Stress Relieving while welding

guru nanak stress relievers pvt. ltd., offers services of vibratory stress relief, by ‘formula 62’ equipment, usa, anywhere in india, for: 1. heavy fabrications 2. fabricated structures 3. weld repaired jobs 4. castings 5. stainless steel 6. aluminium 7. machined components for maintaining dimensional stability 'formula 62' vibratory stress relieving technology is useful in industries like: 1. aerospace 2. automotive 3. cement 4. casting 5. machine building and machining 6. mining 7. mold making 8. power generation 9. railways 10. ship building 11. sugar 12. welding and fabricators advantages of 'formula 62' vibratory stress relieving equipment 1. machine is compact & portable and can be taken to the place of stress relieving needs 2. process time 15 to 90 minutes, depending on weight of the job 3. used on wide variety of applications – fabrications, machined components, castings, shafts, gears, weld repaired jobs 4. does not disturb the metallurgical properties like hardness or tensile strength 5. process is very clean – no discoloration, slag or scale 6. single job weighing 500 kgs. to 150 tons can be stress relieved

...more

Vibratory stress relieving services of Machined Jobs

guru nanak stress relievers pvt. ltd., offers services of vibratory stress relief, by ‘formula 62’ equipment, usa, anywhere in india, for: 1. heavy fabrications 2. fabricated structures 3. weld repaired jobs 4. castings 5. stainless steel 6. aluminium 7. machined components for maintaining dimensional stability 'formula 62' vibratory stress relieving technology is useful in industries like: 1. aerospace 2. automotive 3. cement 4. casting 5. machine building and machining 6. mining 7. mold making 8. power generation 9. railways 10. ship building 11. sugar 12. welding and fabricators advantages of 'formula 62' vibratory stress relieving equipment 1. machine is compact & portable and can be taken to the place of stress relieving needs 2. process time 15 to 90 minutes, depending on weight of the job 3. used on wide variety of applications – fabrications, machined components, castings, shafts, gears, weld repaired jobs 4. does not disturb the metallurgical properties like hardness or tensile strength 5. process is very clean – no discoloration, slag or scale 6. single job weighing 500 kgs. to 150 tons can be stress relieved

...more

Vibratory stress relieving services for welded molds

GURU NANAK STRESS RELIEVERS PVT. LTD., offers services of Vibratory Stress Relief, by ‘Formula 62’ Equipment, USA, anywhere in India, for: 1. Heavy Fabrications 2. Fabricated Structures 3. Weld Repaired Jobs 4. Castings 5. Stainless Steel 6. Aluminium 7. Machined components for maintaining dimensional stability 'Formula 62' Vibratory Stress Relieving technology is useful in Industries like: 1. Aerospace 2. Automotive 3. Cement 4. Casting 5. Machine Building and Machining 6. Mining 7. Mold making 8. Power Generation 9. Railways 10. Ship Building 11. Sugar 12. Welding and Fabricators Advantages of 'Formula 62' Vibratory Stress Relieving Equipment 1. Machine is compact & portable and can be taken to the place of stress relieving needs 2. Process time 15 to 90 minutes, depending on weight of the job 3. Used on wide variety of applications – Fabrications, Machined components, Castings, Shafts, Gears, weld repaired jobs 4. Does not disturb the metallurgical properties like hardness or tensile strength 5. Process is very clean – no discoloration, slag or scale 6. Single job weighing 500 kgs. to 150 tons can be stress relieved

...more

Vibratory stress relieving services for stainless steel

GURU NANAK STRESS RELIEVERS PVT. LTD., A. sole authorized DISTRIBUTOR in India for the 'Formula 62' Vibratory Stress Relief Equipment, manufactured by Stress Relief Engineering, California, USA, and marketed worldwide by Dreyfus Global Trade, LLC, New York, USA B. offers SERVICES of vibratory stress relieving, anywhere in India, by ‘Formula 62’ Equipment, USA, for: 1. Heavy Fabrications 2. Fabricated Structures 3. Weld Repaired Jobs 4. Castings 5. Stainless Steel 6. Aluminium 7. Machined components for maintaining dimensional stability 'Formula 62' Vibratory Stress Relief technology is useful in Industries like: 1. Aerospace 2. Automotive 3. Cement 4. Casting 5. Machine Building and Machining 6. Mining 7. Mold making 8. Power Generation 9. Railways 10. Ship Building 11. Sugar 12. Welding and Fabricators Advantages of 'Formula 62' Vibratory Stress Relief Equipment 1. Machine is compact & portable and can be taken to the place of stress relieving needs 2. Process time 15 to 90 minutes, depending on weight of the job 3. Used on wide variety of applications – Fabrications, Machined components, Castings, Shafts, Gears, weld repaired jobs 4. Does not disturb the metallurgical properties like hardness or tensile strength 5. Process is very clean – no discoloration, slag or scale 6. Single job weighing 500 kgs. to 150 tons can be stress relieved 7. Cost of vibratory stress relieving is approx 50% less than that of thermal stress relieving

...more

Vibratory stress relieving services for Heavy Fabrications

GURU NANAK STRESS RELIEVERS PVT. LTD., A. sole authorized DISTRIBUTOR in India for the 'Formula 62' Vibratory Stress Relief Equipment, manufactured by Stress Relief Engineering, California, USA, and marketed worldwide by Dreyfus Global Trade, LLC, New York, USA B. offers SERVICES of vibratory stress relieving, anywhere in India, by ‘Formula 62’ Equipment, USA, for: 1. Heavy Fabrications 2. Fabricated Structures 3. Weld Repaired Jobs 4. Castings 5. Stainless Steel 6. Aluminium 7. Machined components for maintaining dimensional stability 'Formula 62' Vibratory Stress Relief technology is useful in Industries like: 1. Aerospace 2. Automotive 3. Cement 4. Casting 5. Machine Building and Machining 6. Mining 7. Mold making 8. Power Generation 9. Railways 10. Ship Building 11. Sugar 12. Welding and Fabricators Advantages of 'Formula 62' Vibratory Stress Relief Equipment 1. Machine is compact & portable and can be taken to the place of stress relieving needs 2. Process time 15 to 90 minutes, depending on weight of the job 3. Used on wide variety of applications – Fabrications, Machined components, Castings, Shafts, Gears, weld repaired jobs 4. Does not disturb the metallurgical properties like hardness or tensile strength 5. Process is very clean – no discoloration, slag or scale 6. Single job weighing 500 kgs. to 150 tons can be stress relieved 7. Cost of vibratory stress relieving is approx 50% less than that of thermal stress relieving

...more

Vibratory stress relieving services for castings

GURU NANAK STRESS RELIEVERS PVT. LTD., A. sole authorized DISTRIBUTOR in India for the 'Formula 62' Vibratory Stress Relief Equipment, manufactured by Stress Relief Engineering, California, USA, and marketed worldwide by Dreyfus Global Trade, LLC, New York, USA B. offers SERVICES of vibratory stress relieving, anywhere in India, by ‘Formula 62’ Equipment, USA, for: 1. Heavy Fabrications 2. Fabricated Structures 3. Weld Repaired Jobs 4. Castings 5. Stainless Steel 6. Aluminium 7. Machined components for maintaining dimensional stability 'Formula 62' Vibratory Stress Relief technology is useful in Industries like: 1. Aerospace 2. Automotive 3. Cement 4. Casting 5. Machine Building and Machining 6. Mining 7. Mold making 8. Power Generation 9. Railways 10. Ship Building 11. Sugar 12. Welding and Fabricators Advantages of 'Formula 62' Vibratory Stress Relief Equipment 1. Machine is compact & portable and can be taken to the place of stress relieving needs 2. Process time 15 to 90 minutes, depending on weight of the job 3. Used on wide variety of applications – Fabrications, Machined components, Castings, Shafts, Gears, weld repaired jobs 4. Does not disturb the metallurgical properties like hardness or tensile strength 5. Process is very clean – no discoloration, slag or scale 6. Single job weighing 500 kgs. to 150 tons can be stress relieved 7. Cost of vibratory stress relieving is approx 50% less than that of thermal stress relieving

...more

Vibratory stress relieving services for aluminium

GURU NANAK STRESS RELIEVERS PVT. LTD., A. sole authorized DISTRIBUTOR in India for the 'Formula 62' Vibratory Stress Relief Equipment, manufactured by Stress Relief Engineering, California, USA, and marketed worldwide by Dreyfus Global Trade, LLC, New York, USA B. offers SERVICES of vibratory stress relieving, anywhere in India, by ‘Formula 62’ Equipment, USA, for: 1. Heavy Fabrications 2. Fabricated Structures 3. Weld Repaired Jobs 4. Castings 5. Stainless Steel 6. Aluminium 7. Machined components for maintaining dimensional stability 'Formula 62' Vibratory Stress Relief technology is useful in Industries like: 1. Aerospace 2. Automotive 3. Cement 4. Casting 5. Machine Building and Machining 6. Mining 7. Mold making 8. Power Generation 9. Railways 10. Ship Building 11. Sugar 12. Welding and Fabricators Advantages of 'Formula 62' Vibratory Stress Relief Equipment 1. Machine is compact & portable and can be taken to the place of stress relieving needs 2. Process time 15 to 90 minutes, depending on weight of the job 3. Used on wide variety of applications – Fabrications, Machined components, Castings, Shafts, Gears, weld repaired jobs 4. Does not disturb the metallurgical properties like hardness or tensile strength 5. Process is very clean – no discoloration, slag or scale 6. Single job weighing 500 kgs. to 150 tons can be stress relieved 7. Cost of vibratory stress relieving is approx 50% less than that of thermal stress relieving

...more

Vibratory Stress Relieving Machine Component

We offer vibratory stress relieving of machine component for mining industry. Guru nanak stress relievers pvt. Ltd., a. sole authorized distributor in india for the 'formula 62' vibratory stress relief equipment, manufactured by stress relief engineering, california, usa, and marketed worldwide by dreyfus global trade, llc, new york, usa b. offers services of vibratory stress relieving, anywhere in india, by formula 62 equipment, usa, for: 1. heavy fabrications 2. fabricated structures 3. weld repaired jobs 4. castings 5. stainless steel 6. aluminium 7. machined components for maintaining dimensional stability 'formula 62' vibratory stress relief technology is useful in industries like: 1. aerospace 2. automotive 3. cement 4. casting 5. machine building and machining 6. mining 7. mold making 8. power generation 9. railways 10. ship building 11. sugar 12. welding and fabricators advantages of 'formula 62' vibratory stress relief equipment 1. machine is compact & portable and can be taken to the place of stress relieving needs 2. process time 15 to 90 minutes, depending on weight of the job 3. used on wide variety of applications like fabrications, machined components, castings, shafts, gears, weld repaired jobs 4. does not disturb the metallurgical properties like hardness or tensile strength 5. process is very clean; no discoloration, slag or scale 6. single job weighing 500 kgs. To 150 tons can be stress relieved 7. cost of vibratory stress relieving is approx 50% less than that of thermal stress relieving

...more

Vibratory stress relieving of finished molds

guru nanak stress relievers pvt. ltd., offers services of vibratory stress relief, by ‘formula 62’ equipment, usa, anywhere in india, for: 1. heavy fabrications 2. fabricated structures 3. weld repaired jobs 4. castings 5. stainless steel 6. aluminium 7. machined components for maintaining dimensional stability 'formula 62' vibratory stress relieving technology is useful in industries like: 1. aerospace 2. automotive 3. cement 4. casting 5. machine building and machining 6. mining 7. mold making 8. power generation 9. railways 10. ship building 11. sugar 12. welding and fabricators advantages of 'formula 62' vibratory stress relieving equipment 1. machine is compact & portable and can be taken to the place of stress relieving needs 2. process time 15 to 90 minutes, depending on weight of the job 3. used on wide variety of applications – fabrications, machined components, castings, shafts, gears, weld repaired jobs 4. does not disturb the metallurgical properties like hardness or tensile strength 5. process is very clean – no discoloration, slag or scale 6. single job weighing 500 kgs. to 150 tons can be stress relieved

...more

Vibratory Stress Relief Services

Our services for on-site Vibratory Stress Relief, by ‘Formula 62’ Equipment, USA, is available anywhere in India for: 1. Heavy Fabrications 2. Fabricated Structures 3. Weld Repaired Jobs 4. Castings 5. Stainless Steel 6. Aluminium 7. Machined components for maintaining dimensional stability Single job piece of 500 ks up to 150 tons (irrespective of its shape, size or volume) can effectively be stress relieved by the 'Formula 62' VSR Equipment - without disturbing the metallurgical properties of the parent material and with cost less than 30% than that of thermal stress relieving.

...more

Vibratory Stress Relief services of metals

guru nanak stress relievers pvt. ltd., offers services of vibratory stress relief, by ‘formula 62’ equipment, usa, anywhere in india, for: 1. heavy fabrications 2. fabricated structures 3. weld repaired jobs 4. castings 5. stainless steel 6. aluminium 7. machined components for maintaining dimensional stability 'formula 62' vibratory stress relieving technology is useful in industries like: 1. aerospace 2. automotive 3. cement 4. casting 5. machine building and machining 6. mining 7. mold making 8. power generation 9. railways 10. ship building 11. sugar 12. welding and fabricators advantages of 'formula 62' vibratory stress relieving equipment 1. machine is compact & portable and can be taken to the place of stress relieving needs 2. process time 15 to 90 minutes, depending on weight of the job 3. used on wide variety of applications – fabrications, machined components, castings, shafts, gears, weld repaired jobs 4. does not disturb the metallurgical properties like hardness or tensile strength 5. process is very clean – no discoloration, slag or scale 6. single job weighing 500 kgs. to 150 tons can be stress relieved

...more

Vibrating stress relieving services for Forged Steel

guru nanak stress relievers pvt. ltd., offers services of vibratory stress relief, by ‘formula 62’ equipment, usa, anywhere in india, for: 1. heavy fabrications 2. fabricated structures 3. weld repaired jobs 4. castings 5. stainless steel 6. aluminium 7. machined components for maintaining dimensional stability 'formula 62' vibratory stress relieving technology is useful in industries like: 1. aerospace 2. automotive 3. cement 4. casting 5. machine building and machining 6. mining 7. mold making 8. power generation 9. railways 10. ship building 11. sugar 12. welding and fabricators advantages of 'formula 62' vibratory stress relieving equipment 1. machine is compact & portable and can be taken to the place of stress relieving needs 2. process time 15 to 90 minutes, depending on weight of the job 3. used on wide variety of applications – fabrications, machined components, castings, shafts, gears, weld repaired jobs 4. does not disturb the metallurgical properties like hardness or tensile strength 5. process is very clean – no discoloration, slag or scale 6. single job weighing 500 kgs. to 150 tons can be stress relieved

...more

Stress relieving of machined work piece

As per customers requirement Metric Ton (MOQ)

GURU NANAK STRESS RELIEVERS PVT. LTD.: A. Sole authorized DISTRIBUTOR in India for the 'Formula 62' Vibratory Stress Relief Equipment, manufactured by Stress Relief Engineering, California, USA, and marketed worldwide by Dreyfus Global Trade, LLC, New York, USA B. Offers SERVICES of vibratory stress relieving, anywhere in India, by Formula 62 VSR Equipment, USA, for: 1. Heavy Fabrications 2. Fabricated Structures 3. Weld Repaired Jobs 4. Castings 5. Stainless Steel 6. Aluminium 7. Machined components for maintaining dimensional stability 'Formula 62' Vibratory Stress Relief technology is useful in Industries like: 1. Aerospace 2. Automotive 3. Cement 4. Casting 5. Machine Building and Machining 6. Mining 7. Mold making 8. Power Generation 9. Railways 10. Ship Building 11. Sugar 12. Welding and Fabricators Advantages of 'Formula 62' Vibratory Stress Relief Equipment 1. Machine is compact & portable and can be taken to the place of stress relieving needs 2. Process time 15 to 90 minutes, depending on weight of the job 3. Used on wide variety of applications like Fabrications, Machined components, Castings, Shafts, Gears, weld repaired jobs 4. Does not disturb the metallurgical properties like hardness or tensile strength 5. Process is very clean-no discoloration, slag or scale 6. Single job weighing 500 kgs. to 150 tons can be stress relieved 7. Cost of vibratory stress relieving is approx 50% less than that of thermal stress relieving 8. Process is environmentally friendly

...moreOpening Hours