heat treatment furnace

Get Price Quote

1 Piece (MOQ)

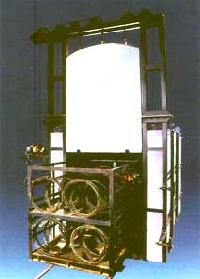

Details: Heat Treatment Furnaces for Various application Annealing , Normalising Hardening , Solution Treatment Heating , Forge Heating , Tempering Aluminum Solutionising , Stress Relieving , Ductile Iron Full Annealing Strong rigid construction , Heat resistant grade CI castings at door and frame, bogie and furnace interface eliminates warpage. Railway rails for load bearing under temperature. Double sealing minimizing heat losses Thermal survey as per API 6A Standard. All measuring instruments calibrated to national traceability With as per the Required AUTOMATION. Applications Annealing Normalising Hardening Solution Treatment Heating Forge Heating Tempering Aluminum Solutionising Stress Relieving Ductile Iron Full Annealing. Auto cycle control Ramp, Soak, Cool ..... 8 Steps Profile 10, 20 Profile Memory Multi Input Multi Output (MIMO) PID Controlling Action. Micro processor based programable controller. one burner, one thermocouple forms one pair as zone, thus multi zone control Digital display for time temprature graph online with USB pendrive for data storage, Wired lan PC connectivity for real time graph printing Firing High Velocity Short Flame Burner Direct On/Off pulse firing effect. Smokeless perfect combustion The furnaces are calibrated for uniformity as per API 6A Standard ( The Temperature Difference Between Highest & Lowest Points at Stabilised Conditions should not be more than 13ºC.) Mechanization Trolley - movement by geared motor with brake. Door - movement by geared motor with brake, counter weighed, Door Lock Unlock - innovative,Pneumatically operated instant latching unlatching for perfect sealing Construction Strong rigid construction Heat resistant grade CI castings at door and frame, bogie and furnace interface eliminates warpage. Railway rails for load bearing under temperature. Double sealing minimising heat losses. Insulation High temperature high density ceramic fibre modular lining. Self supporting U-fold door lining. Recuperator All fuel fired furnaces are equiped with recuperator to recover the heat from flue gases by preheating combustion air. By thumb rule a rise of 150 degree C in combustion air 7.5% heat is recovered. PLC control Large furnaces handle high value materials, it is essential to install PLC for opration to avoid manual errors. PLC checks each & every operation prior to loading of materials called booting to ensure air/gas/power etc. are within the specifications & all the sensors are in working condition PLC monitors each & every operation during auto cycle for supply conditions, flue temperatures burner operations any deviation is automatically notified audio visualy & through SCADA PLC keeps event history for the record Control Panel Aesthetically powder coated control panel. Electrical switch gears for drives, burners. Status indication and control. Burner sequence controller and flame failure device. Programmable startup, burner, temperature controlling system. Calibrations Thermal survey as per API 6A Standard. All measuring instruments calibrated to national traceability

industrial heat treatment furnaces

200,000 Per unit

Best Deals from Heat Treatment Furnaces

heat treatment furnace

72,800 - 750,000 Per Piece

spring produced on automatic machine gives dimensional accuracy. while forming and coiling springs, wire gets stress, which affect the spring function as well as life. for high accuracy stress releaving digitally controlled furnace are required. by keeping in mind we designed and developed digital control furnace for exact customer need. up to 5 kw/ 9 kw furnace designed in box type. for more production need conveyortempering furnaces are used. temperature and timer are digitally controlled by special electrical control panel. specificationsmodels df -5df - 9dcf -25 wattage (kw) 5 9 25 type tray (trolly) tray(trolly) conveyor temperature (5000 c) digital digital digital timer digital digital digital isulation cerwool & glasswool cerwool glasswool cerwool, glasswool & air curton accuracy better than +- 30 c better than +- 30 c better than +- 3 0c

heat treatment furnace

Get Price Quote

Heat Treatment Furnaces

Get Price Quote

We are a trusted name, engrossed in manufacturing, supplying & exporting of Heat Treatment Furnaces from Maharashtra, India. Our Roller Hearth Furnaces are designed and manufactured in accordance with industry standards and market demands. Our Mesh Belt Furnaces have attracted various national as well as international clients due to their unmatched quality and unsurpassable performance. One can get them at reasonable prices, from us. More about Heat Treatment FurnacesHeat Treatment Furnace provides strength to products through heat processing. The Heat Treatment Furnace range is available in resistance heated and gas/oil fired versions. The Heat Treatment Furnace range offered by us can accommodate a variety of materials and treatment goals through the use of optimized settings for heating and cooling temperatures, wait times, heating and cooling speeds, and ambient conditions. Our Heat Treatment Furnace comes with automatic equipment such as Temperature Controllers, PLC, Thyristor, SCADA etc. The use of quality raw materials in the manufacturing makes the furnaces durable, strong and resistant to adverse conditions. We are well reputed for the consistency and precision of the temperature in the entire heating zone of such furnace. Features : Transfer Mechanism : Roller hearth or Conveyor Chain Semi-continuous, indexing type design Electrically or Gas Heated Re-circulation Fans to ensure temperature uniformity better than +/- 5 degree C Agitators in Quench tank ensure uniform quenching Pneumatically Operated Dampers for Sand Removal Quench Delay : 15-20 seconds.c Automatic Sand Removal from quench tank ,Optional Air Quench Facility ,PLC controlled Capacity : 100 kgs / hour to 2000 kgs / hour.

heat treatment furnace

100,000 Per Piece

Heat Treatment Furnaces

Get Price Quote

We offer comprehensive problem solving approach to the industrial heating requirements by heat treatment services through our precision engineered general heat treatment components. These components are specifically used for forgings, castings, dies and tool fabrication works through some of the processes such as : AnnealingHardeningTemperingNormalizingSolution Annealing

heat treatment furnace

Get Price Quote

Applications Annealing Normalising Hardening Solution Treatment Heating Forge Heating Tempering Aluminum Solutionising Stress Relieving Ductile Iron Full Annealing. Auto cycle control Ramp, Soak, Cool ..... 8 Steps Profile 10, 20 Profile Memory Multi Input Multi Output (MIMO) PID Controlling Action. Micro processor based programable controller. one burner, one thermocouple forms one pair as zone, thus multi zone control Digital display for time temprature graph online with USB pendrive for data storage, Wired lan PC connectivity for real time graph printing Firing High Velocity Short Flame Burner Direct On/Off pulse firing effect. Smokeless perfect combustion The furnaces are calibrated for uniformity as per API 6A Standard ( The Temperature Difference Between Highest & Lowest Points at Stabilised Conditions should not be more than 13ºC.) Mechanization Trolley - movement by geared motor with brake. Door - movement by geared motor with brake, counter weighed, Door Lock Unlock - innovative,Pneumatically operated instant latching unlatching for perfect sealing Construction Strong rigid construction Heat resistant grade CI castings at door and frame, bogie and furnace interface eliminates warpage. Railway rails for load bearing under temperature. Double sealing minimising heat losses. Insulation High temperature high density ceramic fibre modular lining. Self supporting U-fold door lining. Recuperator All fuel fired furnaces are equiped with recuperator to recover the heat from flue gases by preheating combustion air. By thumb rule a rise of 150 degree C in combustion air 7.5% heat is recovered. PLC control Large furnaces handle high value materials, it is essential to install PLC for opration to avoid manual errors. PLC checks each & every operation prior to loading of materials called booting to ensure air/gas/power etc. are within the specifications & all the sensors are in working condition PLC monitors each & every operation during auto cycle for supply conditions, flue temperatures burner operations any deviation is automatically notified audio visualy & through SCADA PLC keeps event history for the record Control Panel Aesthetically powder coated control panel. Electrical switch gears for drives, burners. Status indication and control. Burner sequence controller and flame failure device. Programmable startup, burner, temperature controlling system. Calibrations Thermal survey as per API 6A Standard. All measuring instruments calibrated to national traceability

heat treatment furnace

Get Price Quote

The inventory of raw materials has also been maintained by us in order to keep a record of the entire stock. Moreover, the quality of the inputs is strictly checked by our experts before procurement. We own a well-maintained storage facility that helps us in meeting bulk and urgent requirements of the clients at a time. It is managed and maintained by the storekeepers.

Aluminum Heat Treating And Melting Furnace

100,000 Per Units

heat treatment furnace

Get Price Quote

Food Processing Equipment, Power Floater Machine, Screed Board Vibrator

industrial heat treatment furnace

Get Price Quote

industrial heat treatment furnace, Centrifugal Blower, Temperature Sensors

Heat Treatment Furnaces

Get Price Quote

Heat Treatment Furnaces, Thermocouples, Signages, Sensors

heat treatment furnace

Get Price Quote

treatment furnace system

Heat Treatment Furnaces

Get Price Quote

Heat Treatment Furnaces

Heat Treatment Furnaces

Get Price Quote

Heat Treatment Furnaces, Scientific Instruments, welding electrode ovens

heat treatment furnace

Get Price Quote

electrical crucible furnace, Drop Quench Solution Annealing Furnace

heat treatments

Get Price Quote

heat treatments, Induction Hardening, Selective Carburising

Heat Treatment Furnaces

Get Price Quote

Heat Treatment Furnaces, Ceramic Tubes, industrial refineries forging

heat treatment furnace

Get Price Quote