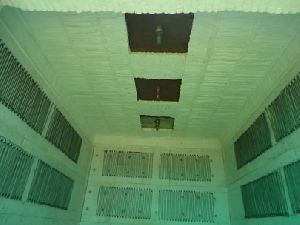

heat treatment furnace

Get Price Quote

1 Piece (MOQ)

Details: Heat Treatment Furnaces for Various application Annealing , Normalising Hardening , Solution Treatment Heating , Forge Heating , Tempering Aluminum Solutionising , Stress Relieving , Ductile Iron Full Annealing Strong rigid construction , Heat resistant grade CI castings at door and frame, bogie and furnace interface eliminates warpage. Railway rails for load bearing under temperature. Double sealing minimizing heat losses Thermal survey as per API 6A Standard. All measuring instruments calibrated to national traceability With as per the Required AUTOMATION. Applications Annealing Normalising Hardening Solution Treatment Heating Forge Heating Tempering Aluminum Solutionising Stress Relieving Ductile Iron Full Annealing. Auto cycle control Ramp, Soak, Cool ..... 8 Steps Profile 10, 20 Profile Memory Multi Input Multi Output (MIMO) PID Controlling Action. Micro processor based programable controller. one burner, one thermocouple forms one pair as zone, thus multi zone control Digital display for time temprature graph online with USB pendrive for data storage, Wired lan PC connectivity for real time graph printing Firing High Velocity Short Flame Burner Direct On/Off pulse firing effect. Smokeless perfect combustion The furnaces are calibrated for uniformity as per API 6A Standard ( The Temperature Difference Between Highest & Lowest Points at Stabilised Conditions should not be more than 13ºC.) Mechanization Trolley - movement by geared motor with brake. Door - movement by geared motor with brake, counter weighed, Door Lock Unlock - innovative,Pneumatically operated instant latching unlatching for perfect sealing Construction Strong rigid construction Heat resistant grade CI castings at door and frame, bogie and furnace interface eliminates warpage. Railway rails for load bearing under temperature. Double sealing minimising heat losses. Insulation High temperature high density ceramic fibre modular lining. Self supporting U-fold door lining. Recuperator All fuel fired furnaces are equiped with recuperator to recover the heat from flue gases by preheating combustion air. By thumb rule a rise of 150 degree C in combustion air 7.5% heat is recovered. PLC control Large furnaces handle high value materials, it is essential to install PLC for opration to avoid manual errors. PLC checks each & every operation prior to loading of materials called booting to ensure air/gas/power etc. are within the specifications & all the sensors are in working condition PLC monitors each & every operation during auto cycle for supply conditions, flue temperatures burner operations any deviation is automatically notified audio visualy & through SCADA PLC keeps event history for the record Control Panel Aesthetically powder coated control panel. Electrical switch gears for drives, burners. Status indication and control. Burner sequence controller and flame failure device. Programmable startup, burner, temperature controlling system. Calibrations Thermal survey as per API 6A Standard. All measuring instruments calibrated to national traceability

heat treatment furnace

72,800 - 750,000 Per Piece

spring produced on automatic machine gives dimensional accuracy. while forming and coiling springs, wire gets stress, which affect the spring function as well as life. for high accuracy stress releaving digitally controlled furnace are required. by keeping in mind we designed and developed digital control furnace for exact customer need. up to 5 kw/ 9 kw furnace designed in box type. for more production need conveyortempering furnaces are used. temperature and timer are digitally controlled by special electrical control panel. specificationsmodels df -5df - 9dcf -25 wattage (kw) 5 9 25 type tray (trolly) tray(trolly) conveyor temperature (5000 c) digital digital digital timer digital digital digital isulation cerwool & glasswool cerwool glasswool cerwool, glasswool & air curton accuracy better than +- 30 c better than +- 30 c better than +- 3 0c

Best Deals from Heating Furnace

industrial heat treatment furnaces

200,000 Per unit

Drop Bottom Furnace

Get Price Quote

We are among topmost Manufacturers, Suppliers & Exporters of Drop Bottom Furnaces in Maharashtra, India. Made from the best quality material, our Drop Bottom Furnaces always comply with industry standards. In addition to this, they have high durability, tensile strength and resistivity to adverse conditions. Our furnaces can also be customized as per the specifications and drawings, provided by the patrons.More about Drop Bottom FurnacesDrop Bottom Furnaces use quality hydraulic system for lift & lowering of charge along with specially designed tackle, which can disengage the hook automatically. In addition, they have safety feature against leakage of hyd. cylinder. Features : Electrically heated or Gas fired. Charge lift / lower by hydraulic or electromechanical Quench tank on motorized trolley or in civil pit PLC controlled sequential operation Quench delay less than 20 seconds Round or rectangular shape

Billet Heating Pusher Furnace

1,000,000 Per ONE

Direct Baleout Type Melting Cum Holding

Get Price Quote

Direct Baleout Type Melting Cum Holding Furnace These furnaces are suitable for HPDC / GDC shops where production rates are required upto 250Kg/Hr for single alloy. This furnace can also be used as central melting furnace for several GDC machines where metal can baled out for the baleout pot provided on furnace and can be fed to GDC machines placed in vicinity. These furnaces uses burner flue for melting of solid aluminium which in terms increases furnace efficiency and reduces melting losses. Distinct benefits of DIRECT BALEOUT TYPE Melting cum Holding furnaces with ONLINE DEGASSING 1.Melting and Holding is done in single chamber. 2.Reverses flow pattern of flue gases ensures higher retention of flue in furnace. 3.Higher retention of flue results in lower fuel consumption and very low melting loss. 4.Continuous melting rate ensures better productivity than batch type furnaces. 5.No blind corners in refractory which allows easy and thorough cleaning of furnace 6.Metal tapping is possible through DIRECT BALEOUT POT. 7.Furnace can be optionally equipped with ONLINE DEGASSING SYSTEM. 8.Additional heat recuperation can be provided as an option.

Controlled Atmosphere Brazing Furnace

Get Price Quote

Controlled Atmosphere Brazing FurnacesTPM Depot has a technical tie-up with Shroyoku Sanggyo Furnace Company. We are Specialized in Controlled Atmospheric Brazing furnaces in India , Aluminum Brazing Furnaces,continuous Aluminum Brazing Furnaces Manufacturers in India. These furnaces are being used for brazing aluminum heat exchangers for automotive and other industrial applications.

confectioners glaze

1,050 - 1,250 Per kg

10 Litre (MOQ)

Panned chocolate or dry fruits coated chocolate polishing and glazing agent

Aluminium Tilt Tilting Crucible Furnace

300,000 Per Piece

Liquid Nitriding Furnace

400,000 Per Units

melting cum holding furnace

250,000 Per Unit

1 Unit (MOQ)

Tempering Furnaces

200,000 Per Piece

Crucible Type Melting Furnace

Get Price Quote

Crucible type melting furnaces are suitable for HPDC GDC shops where production rates are very low or metal quality is extremely crucial and only electric melting is required. Being Batch type indirectly heated furnaces, the furnaces have comparatively higher energy consumption. Recurring cost of CRUCIBLE is also one of the concern since it drastically affects production in case of sudden failure.

aluminium holding furnace

600,000 Per Units

Drop Quench Solution Annealing Furnace

Get Price Quote

Heat treatment of aluminium castings enhances their mechanical properties like UTS, Yield strength, Machinability and hardness. In the solution annealing procces, castings are taken to their eutectic temperature and then rapidly quenched in water. Equipment provided by Energy Systech includes the entire material handling system required to achieve this. Uniformity of temperature in the furnace results in very consistent properties in the castings. Salient Features 1) Strong Elevated structure. 2) Powerful air circulation in circular geometry giving excellent temperature uniformity. 3) Ceramic Fibre lining giving excellent energy economy. 4) Reliable, long life vertical heaters. 5) Mechanical Up/Down motion with “dunking” facility. 6) Powered movement of Tank and Door trolley. 7) Sharp, quick quenching within 15 seconds. 8) Can also act as a Precipitation hardening furnace.

Diffusion furnaces

Get Price Quote

MRL is the brand for Sandvik's semiconductor and solar industry-related heating products. The MRL program also covers a range of other thermal processing equipment.

ANNEAL system

Get Price Quote

Systems are optimised for the thermal treatment of 2D materials and wafers under controlled atmospheres. Substrates are supported face-up on stage-top platens that are situated centrally inside a stainless-steel high-vacuum chamber fitted with appropriate heat shielding and a shuttered viewport. Heating is via a heat source located beneath the platen. Maximum temperatures up to 1000 °C are possible�depending on the heating technology used: ANNEAL systems can be fitted with up to 3 mass flow controllers (MFCs). Typical gases are Ar, O2 and N2, and full scale flow rates are flexible. All systems have wide-range gauges, but for improved accuracy, capacitance manometers are also available. In case chamber pressure is critical, automatic pressure control is available with control resolutions to 0.1 mbar. ANNEAL systems are highly modular and can be configured for a wide range of applications

Vacuum Heat Treatment Furnace

8,500,000 Per Piece

Tilting Type Crucible Furnace

Get Price Quote

Gas Nitriding Furnace

500,000 Per Unit