Wire Mesh Conveyors

HC Wire Mesh Belt Conveyor are used in many industries to move products through process equipment or production lines. Steel mesh belts are made from strips of steel assembled onto rods, and can be mild, galvanized or stainless steel. The length and width of the belt is made to suit the product and application. The belt runs on a steel chevron flat bed with drive sprockets at one end and a tension drum and sprockets at the other. The mesh belt and chevron bed are particularly suited to spraying or drying application as the open design allows air to pass through easily.

...more

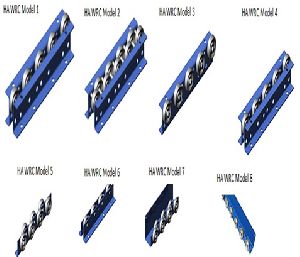

Wheel Rail Conveyors

HC WRB Model 1 : We make a wide range of Roller Conveyors classified as – Powered and non powered version conveyors using standard Precision bearings for heavy loads (250 kgs and above) and pressed bearings for lighter loads.HC WRB Model 2 : Can be utilized as a heavy duty pallet rail. The opposing channels offer a sturdy configuration to cover longer spans, while the staggered wheel pattern conveys irregularly shaped loads. HC WRB Model 3 : Wheel Rail Conveyors provide an economical means of conveying products in flow racks.

...more

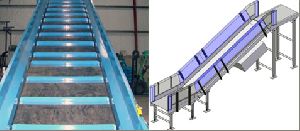

Waste Conveyors

HC Waste Conveyor HC designs and manufactures waste conveyor systems for waste management companies and local authorities. The conveyor shown here is designed to carry waste material from a floor level load area up the incline and into a waste compacting machine. The belt is fixed to steel slats running across the conveyor between 4" pitch conveyor chains. Steel flights are bolted to the belt to aid the waste up the incline.

...more

Warehouse Conveyor Belt

HC Warehouse & Factory Conveyors : HC Logistics providing solutions for your product handling and transportation. All our conveying systems are custom designed for handling your products in warehouses & Factory.

...more

Vibratory Stock Feeders

Hoppers / Stock Feeders : HA eliminate the problems associated with vibratory bowls being overfilled. They provide a consistent supply of parts as well as reduce the need for frequent operator attention to parts level in the bowl. The reduce attention requirements & allow operator to focus on more productive functions of a production line

...more

vibratory linear feeders

HA Linear Feeders : HA in line/linear feeders can be installed in all sorts of environment. We recommend linear feeders with replaceable guides for different sizes of the components. This will again give you trouble free feed rate. They are best suited for high-speed conveyance of small & thin precision pharmaceutical, automobile, glass, electronic & battery parts. Models are available from light duty to heavy-duty type depending upon the component size, thickness,& material type.

...more

vibratory bowl feeders

HA Bowl Units : Bowls have distinct tooling features & the most important factors to consider when selecting the best type of bowl for your particular applications is by determining the component size, its configuration. HA Drive System : HA drive units are correctly engineered to give stable performance at high speed with minimum maintenance. Totally Encapsulated Type coils with adequate power for particular models, are used. An easily removable Safety Guard / Cover giving easy access is provided for the Drive Unit.

...more

Vibratory Bowl Feeder

Ha bowl units : bowls have distinct tooling features & the most important factors to consider when selecting the best type of bowl for your particular applications is by determining the component size, its configuration.

...more

Vehicle Loading and Unloading Conveyors

HC - Low Cost Vehicle and Container Unloader : These are adapted from used conveyors or made from new for specific requirements where the budget is tight or the application is unique. New or used basic conveyors are made or reconditioned to give low cost simple solutions without for example the expanding elements seen on more expensive units.

...more

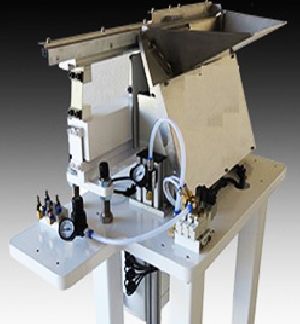

tip forming machine

We are engaged in manufacturing wide range of Tip Forming Machine. These are developed using high grade machines and equipment following the set industry standards and quality norms. These are widely acclaimed in the market for their low maintenance, easy installation, high performance and durability.

...more

Syringe Auto Feeders

We have designed this special bowl feeder to feed various sizes of assembled syringe from 3ml to 10 ml in single bowl or directly through roller shaft for bulk feeding requirement. For more information on Syringe Feeding Technology or for individual parts requirement i.e Barrel, Plunger, Rubber Gasket, Needle please contact the team, who will be more than happy to advise

...more

stepper feeders

HA's range of stepped feeders operates on the principle of a series of interrelating blades that lift the components from the integral bulk hopperThe movement is electrically, pneumatically or hydraulically powered, depending on the application.The components being handled are discharged from the top blades onto a vibratory linear feeder or conveyor transfer track, where they are selected and orientated into the required position for presentation to machines or equipment for further operations

...more

Spring Seprator Auto Feeder Systems

HA continues to fulfill the requirements for its customers who require spring feeding . Here we produces our own patented range of spring feeding technology, which it sells worldwide. This technology continues to enable manufacturing and assembly companies throughout the world to accurately and reliably feed and insert springs into the most complex of assemblies. CPR prides itself on the continued supply of this equipment after many decades in the market. H+A produces equipment which will separate and feed springs of many varieties, for both integration into assembly equipment or for utilizing on operator load positions. For more information on spring feeding technology, please contact the team, who will be more than happy to advise.

...more

Slated Belt Elevators

Slatted belt elevator feeders are suitable for the selection, orientation and feeding of components to automatic machines, or for bulk loading of components to vibratory bowl feeders and hoppers. When components are to be selected, orientated and fed direct to automatic machines or billet heating furnaces etc., the selection and orientation is carried out on a linear vibratory feeder, which is an integral part of the belt elevator feeder or alternatively on a gravity discharge track. This will depend upon the components to be handled and the automatic machine layout. The slatted belts can be case hardened mild steel, stainless steel or plastic. Belt elevator feeders are manufactured to customer’s specific requirements.

...more

Slat Conveyors

HC Slat Conveyor are ideal for applications where belt or roller conveyors are not suitable, i.e high temperature ovens, heavy products or dirty and arduous conditions. Slat Conveyors work on a basic simple design, twin stands of conveyor chain run parallel within guides and around sprockets either end. The drive is mounted on one end and the tension device the opposite end. Slats made of steel (normally galvanised or stainless), hard wood or plastic are bolted between the chains, effectively making a moving 'table' surface. The length of the conveyor and width of the slats is made to suit the product being carried.

...more

Single Step Feeders

This model is a “single-step” step feeder capable of feeding small cylindrical and spherical parts. It offers numerous advantages over conventional feeding methods, including quiet operation, space savings and gentle handling of parts. This is available as a standalone unit, but is usually integrated with other components. HA - Single Step Feeder Model - Low Cost Automates Feeding of Small Cylindrical and Spherical Parts.How it works ?Bulk parts are lifted out of the integrated hopper bin by the step. The step thickness is selected so that a single row of parts is lifted. At the top of the step stroke, the parts drop onto a straight line track (vibratory inline, belt conveyor or air track), where additional orientation can be performed. Mis-oriented parts ejected from the orienting track can often drop directly back into the bin, or can be returned to the bin via gravity slide, air track or conveyor in situations where more complex orientation is performed on the orienting track.

...more

Shaft Auto Feeder Feeding Systems

We have designed this special purpose machine to dispense shaft size 7 mm to 1 inch thick automatically for grinding etc. purposes. we can feed the shaft up to 13inch long shaft up to 50 shafts at a time. For more information on spring feeding technology, please contact the team, who will be more than happy to advise.

...more

Screw Conveyors

Screw conveyors provide an efficient and reliable method of conveying a wide range of industrial bulk materials such as grain, flour and feed stuff to industrial products as e.g. limestone, fly ash & wood pellets. The screw conveyors are of modular construction consisting of inlet and outlet sections, trough section with screw flight and the drive assembly.

...more

Screw / Bolt / Nut / Washer Feeders

Hindustan Automation has introduced a new feeder that can feed screws, bolts, nuts and washers of all different sizes in a single bowl of each type. Common bowl is used for all the variant sizes of each type which varies from M4 to M12. You simply dump the screws, Bolts and Washers into the bowl feeder and they come out in desired orientation. This vibratory bowl feeder adds tremendous value for users of fasteners who presently have to assemble screws and washers by hand or have to use costly assembly equipment.

...more

Rotary Turn Table

HA Rotary Turn Table are constructed in stainless steel making it suitable for the food, beverage and pharmaceutical industry amongst others. HA Rotary Tables are fitted with a fixed speed 4.7 r.p.m. gearbox as standard. Special speeds can be offered at no extra cost. HA Table Tops run true to 1.5mm in deflection. This therefore ensures a very close transfer from or to the feeding conveyor.All of HA Rotary Turn Tables are fitted with a stop start button as standard. The tables can be fitted with a variable speed controller and can be made mobile if required both of these options are extra.

...more

Rotary centrifugal feeders

The HA range of centrifugal feeders are non vibratory and operate by a continuous rotary motion. They are ideal for orientating and feeding many different types and sizes of components at very high rates of feed compared with other types. HA Centrifugal feeders are quieter in operation and offer much smoother handling of components, therefore less component damage is caused. The components are fed by the centrifugal disc and distributed onto an outer rim where they are selected and orientated into the required position. They then discharge via the feeder outlet into a gravity discharge track or take off transfer conveyor.

...more

Plate Link Chain Conveyors

HC Plate Link Conveyors are normally used in arduous applications to move bulk items like waste material, swarf and scrap metal. The belt is constructed from heavy duty steel links connected by steel rods. This makes the belt strong but flexible. The links are fixed to conveyor chains either side that run in steel guides on over sprockets at each end. The length of the conveyor and width of the plate link belt is variable depending on the product being carried. The conveyor can be level or inclined to feed material in to hoppers or skips.

...more

pallet conveyors

HC Pallet conveyors are heavy unit load conveyor systems that have the durability and versatility to work efficiently in a wide variety of applications and industries. Whether you need to transport, stop and accumulate, reorient, or stage loads, HC has the technology and expertise to develop and maintain the ideal pallet conveyor system for you. HC pallet handling equipment is available in Medium Duty and Heavy Duty model ranges to cater for variations in the weight of loaded pallets. HC pallet conveyor systems have the strength and versatility to work efficiently in a wide variety of applications and industries.Special Features : • Flexible for ease of customization • Can be easily integrated into existing pallet handling system • Discharge height as per request.• Adapted for different standard pallet sizes

Feature : Can be easily integrated into existing pallet handling system

...more

Overhead Conveyors

HC Model – 4 Wheel Trolley : Consists of a 4 wheeled trolley with load capacity of 37.5Kg running through a high quality mild steel tubular track section of 41mm o/d and 3mm wall thickness. Trolleys can be doubled up over a load bar to take greater loads depending on product dimensions.HC Model – Two Wheel Trolley : One of our best selling systems the 228FT has become a great success in the window and door industry. The trolleys are rated at 50Kg and run through the 50mm2 228 track.HC Model – Eight Wheel Trolley : The heavyweight of the free track systems taking loads of up to 1000Kg. Consisting of an 8 wheeled trolley running through our 406 track. The track section is fabricated from dual top hat sections at maximum 3m lengths with bridge plates incorporated every 750mm.HC Model - Carriers : Multiple types of carriers can be applied to trolleys or load bars. Manual rotators, indexers, sprocket rotators are all available for your specific needs.

...moreBe first to Rate

Rate ThisOpening Hours