Water Cooled Heat Exchanger

20,000 Per Piece

Frequency : 50/60 Hz

Usage : Industrial

Material : Mild Steel

Brand Name : HRS

Medium used : Water

Country of Origin : Made in India

...more

Unicus Scraped Surface Heat Exchanger

Unicus is capable of generating high levels of turbulence in products of high viscosity increasing substantially the overall heat transfer coefficient. In addition it does not allow the formation of any fouling layers on the inner tube surfaces and always stays clean enabling the unit to work in the optimum condition for efficient heat transfer at all times.

...more

Unicus (hrs 002)

We manufacture unicus.

Unicus (hrs 001)

We manufacture unicus.

Uht Sterilizer

The UHT Sterilizer by HRS is based on ultra heat treatment technology and has a complete hygienic design to give the final output. It can be customized to suit varied capacity and a special provision for future capacity expansion is an additional advantage. Specially designed Ecoflux* Corrugated Tube Heat Exchanger based Aseptic Sterilizer, Provision to direct intermediate milk to deaerator & homogenizer.

...more

Stainless Steel Plate Heat Exchanger

20,000 Per Piece

Speciality : Well-researched in-house design , Variations in plate embossing for highest efficiency

Usage : For HVAC and Refrigerator

Type : Plate

Brand Name : Alfa Laval

Medium used : Water, chemical

Country of Origin : Made in India

...more

Stainless Steel Heat Exchanger

Smooth Tube Heat Exchanger for various industrial application like heating, cooling, condensing and reboiling in our world class manufacturing facility to cater to Customer's heat transfer requirement. We manufacture units presently to working pressure of 80 bar for process service plant and with 0 temperature upto 400 C. For specific design we can manufacture units with 150 bar pressure at 500 C. Our manufacturing facility is equipped to fabricate STHE with diameter of 2000 mm and tube length upto 9000 mm. For special equipment we can make heat exchanger with 12000 mm tube length. These are customised units based on specific industry application. The units can be fabricated based on customer drawings. We can design and manufacture units to customer specifications too. We design STHE with or without ASME 'U' stamp certification, CE certification and others codes.

...more

Smooth Tube Heat Exchanger

Type : Tube Heat Exchangers

Material : Gun Metal, Metal, Mild Steel, Stainless Steel

Weight : 100-1000kg, 1000-2000kg, 2000-3000kg, 3000-4000kg, 4000-5000kg

Color : Blue, Brown, Green, Grey, LIght White, Silver, White

Voltage : 110V, 220V, 380V, 440V

Condition : New, Used

Automatic Grade : Automatic, Fully Automatic, Manual, Semi Automatic

Power : 1-3kw, 3-6kw, 6-9kw, 9-12kw

Warranty : 1 Year, 2 Years

Driven : Electric

...more

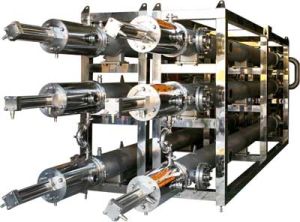

Shell & Tube Heat Exchanger

Hrs process systems limited a trusted name for heat transfer technology in india designs and manufactures ecoflux* smooth tube heat exchangers (sthe) for various industrial applications in range of process industries like heating, cooling, condensing and reboiling. hrs heat exchangers are manufactured in state-of-the-art manufacturing facility to cater to range of heat transfer requirements. Hrs has expertise to manufacture sthes with 150 bar pressure at 500 o c for specific range of designs. For regular requirements these units are manufactured to working pressure of 80 bar for process service plant with temperature upto 400 o c. ecoflux* smooth tube heat exchangers can be customised based on specific industry applications. Ecoflux* sthes are offered with diameter up to 2000 mm and tube length up to 9000 mm. To cater to some special process requirements heat exchangers can be made with 12000 mm tube length as well. Hrs heat exchangers can be designed with coveted asme 'u' stamp standards, ce certification and others codes if required. ecoflux* smooth tube heat exchangers are offered in materials like stainless steel ss304l, ss316l, hastelloy, copper, cu-ni alloys, titanium, al6xn depending on process requirement. features: â�¢ flexible in design, customised solutions â�¢ thermal design in htri and chemcad software â�¢ mechanical design in pvd and pv elite software â�¢ tema configurations available like bem, bet, bku, aes, ael, etc. Â�¢ designed with asme 'u' stamp standards, ce certification and others codes. advantages: â�¢ suitable for high temperature & pressure applications â�¢ wide choice of material of construction applications: â�¢ condenser â�¢ cooler â�¢ heater â�¢ recuperator â�¢ reboiler â�¢ regenerator â�¢ he based systems

...more

scraped surface heat exchangers

Scraped Surface Heat Exchanger

50,000 Per Piece

1 Piece (MOQ)

Speciality : It is Economical with total product recovery and easy maintenance , The design of the heat exchanger allows hygienic or industrial construction , Drastic reduction in production losses.

Usage : Industrial,Food Process Industry

Type : Air-Cooled

Frequency : 50/60 HZ

Voltage : 220-240 Volts

...more

Process Evaporator - (hrs Pe002)

We are one of the preeminent manufacturers and suppliers of Process Evaporator (HRS PE002) in the market. We offer high quality Process Evaporator (HRS PE002), which is highly acclaimed for efficient performance and durability. Strong and safe, these are manufactured according to client’s requirements.

...more

Process Evaporator - (HRS PE001)

We are one of the preeminent manufacturers and suppliers of Process Evaporator (HRS PE001) in the market. We offer high quality Process Evaporator (HRS PE001), which is highly acclaimed for efficient performance and durability. Strong and safe, these are manufactured according to client’s requirements.

...more

Pasteurisation Systems

The preheating or pasteurization system can be integrated with evaporators, sterilizers and fillers as per customer requirement. Accurate automation through these systems minimizes intervention of operator thereby reducing errors. Additionally, HRS also provides systems for chilling or freezing pulp as required for frozen pulp filling and storage. Skid with ECOFLUX* MI series heat exchangers and skid-mounted balance tank, Hygienic, screw type positive displacement pump and sanitary type flow diversion valves.

...more

Plate Heat Exchangers for Energy & Power Ind.(HRS PHE 002)

We have acquired exclusive rights by the way of license manufacturing agreement for design, manufacture, supply and service of Plate Heat Exchangers, with FUNKE Waermaustauscher GmbH! HRS Process Systems Limited is part of the HRS Group with headquarters in UK.

...more

Plate Heat Exchangers for chemical ind.(HRS PHE 001)

# Asymmetrical flow gap available for the most costeffective solution. # Use of smallest temperature difference

...more

Plate Heat Exchanger Gaskets

The heart of a PHE is a pack of embossed plates with apertures. The plates are assembled in a 180° angle to each other, resulting in flow gaps on each side. Each plate is provided with a gasket, which securely seals the flow gaps from the atmosphere and separates the two media used in the heat exchange.The gasketed plate pack is mounted in a rack and is compressed with tightening bolts between the fixed plate and the movable plate. To guarantee maximum heat transfer, warm and cold media are normally fed through the PHE in one-pass or multi-pass counter flow.

...more

Plate Heat Exchanger

Type : Plate Heat Exchangers

Material : Gun Metal, Metal, Mild Steel, Stainless Steel

Weight : 100-1000kg, 1000-2000kg, 2000-3000kg, 3000-4000kg, 4000-5000kg

Color : Blue, Brown, Green, Grey, LIght White, Silver, White

Voltage : 110V, 220V, 380V, 440V

Condition : New, Used

Automatic Grade : Automatic, Fully Automatic, Manual, Semi Automatic

Power : 1-3kw, 3-6kw, 6-9kw, 9-12kw

Warranty : 1 Year, 2 Years

Driven : Electric

...more

plain tube

The corrugations induce turbulence in the media and ensure high Reynolds number even at low velocity. The development of corrugated tube is perhaps the most exciting advancement in heat transfer technology. Corrugated tube is produced by indenting a plain tube with a spiral pattern. No tube wall thinning takes place & no strength is lost.

Feature : A smooth indented inner profile ensures easy cleaning

...more

Piston Pump

We are one of the preeminent manufacturers and suppliers of Piston Pumps in the market. The traditional pumps, find it hard to pump products with high viscosity upwards, which contain thick particles. Due to the thick consistency of these products the working of the Piston Pumps gets hampered. Finding the answers to all these problems, we have come up with our unique Piston Pumps that works efficiently on low power without breaking the product. Attributes :Delivers high flow rates (up to 12 m3/hr)Works under vacuumSelf -primingMinimum spare parts requiredDoes not let any impurities near the productWorks at high temperatures (100ºc)Adjustable flow the hrs piston pumpCompletely hygienic design Applications :Optical coating systemsLamp manufacturing industriesTV tube manufacturing industriesFood processing industriesEpoxy mixing & casting.

...more

Nutraceuticals Processing Systems

An independent multiple circuit CIP system is engineered with the nutraceutical processing system for large plants. The entire integration can be done with separate control panels for main unit & CIP system. Sanitary design for aseptic processing environment, Complete with SS tanks for batches and collection of diverted product.

...more

mechanical evaporator

The different choice of evaporation process technology depends on factors such as thermal characteristics of the product, input rate, concentrate required and the available energy supply. The evaporator types are:Forced Circulation Evaporator,Falling Film Evaporator,Rising Film Evaporator

...more

Juice Pasteurizer

Condition : New, Old

Power : 1-3 Kw, 3-6 Kw , 6-9 Kw , 9-12 Kw ,12-15 Kw

Warranty : 1 Year , 2 Year

Material : Stainless Steel , Mild Steel , Other

Weight : 100-500 Kg , 500-1000 Kg , 1000-5000 kg

...more

Integrated Automated CIP Station

CIP is a method of cleaning the interior surfaces of pipes, vessels, process equipment and other associated fittings, without disassembly. CIP is generally carried out with chemical solutions mainly bases like caustic soda and acids like nitric acid, to clean the organic and inorganic solid deposits on the tube surfaces. The chemical cleaning is followed by flushing with neutral water to wash out any traces of the bases or acids.

...moreBe first to Rate

Rate ThisOpening Hours