Used Lathe Machine

Used lathe machine Option of Flat Bed as well as 45 Degree Slant Bed. Option of 8 station and 4 station production type Automatic turret.

...more

turret lathe

Turret lathe Linear motion Guideways and C3 class ballscrews, Option of 8 station and 4 station production type Automatic turret.

...more

turning lathes

Turning lathes Indigenously designed & manufactured patterns & high quality FG32 grade castings, Linear motion Guideways and C3 class ballscrews.

...more

Turning chuck

Turning chuck Industrial controllers from Siemens and Fanuc, Indigenously designed & manufactured patterns & high quality FG32 grade castings.

...more

tool room lathe

Tool room lathe Complete training and installation at no extra cost, Indigenously designed & manufactured patterns & high quality FG32 grade castings

...more

Tabletop cnc mill

Tabletop cnc mill Three Dimensional Simulation as well as dynamic machining, Servo Motors and Servo Drives from Mitsubishi Siemens

...more

spm milling machine

SPM milling machine are provided to distinguish three phase and single phase power supplies. It gives participants necessary confidence and basic understanding of the electrical control panel.

...more

Spindle Motors

Spindle motors Can be used for light production work, Industrial controllers from Siemens and Fanuc. Complete training and installation at no extra cost.

...more

Spindle Mops

Spindle mops Industrial Tool Changer (For Semiproduction Machines), Three Dimensional Simulation as well as dynamic machining.

...more

spindle drives

Spindle drives Linear motion Guideways and C3 class ballscrews. Option of 8 station and 4 station production type Automatic turret.

...more

Slant Bed CNC Lathe

Slant bed cnc lathe Authorised Distributors for Fanuc India products, Option of Flat Bed as well as 45 Degree Slant Bed.

...more

Single Vane Pump

Single vane pump Aluminium Alloy mounting panel for quick mounting and dismounting. Hydraulic System Test pressure of 70 Bar and continuous operating pressure of 40 Bar

...more

Single-acting compressor

Single-acting compressor Aluminium Alloy mounting panel for quick mounting and dismounting. Pneumatic circuits can be designed in software and the same can be demonstrated on training kit.

...more

single acting air cylinder

Single acting air cylinder Aluminium Alloy mounting panel for quick mounting and dismounting. Pneumatic circuits can be designed in software and the same can be demonstrated on training kit.

...more

Siemens Maintenance Training Kits

Controller: Siemens Industrial Controller Controller Model: 828D Spindle: Analog with Encoder / Siemens Servo Mechanical Slides: With Linear Motion Guideways Automatic Lubrication CNC Maintenance kits are designed to provide hands on experience to CNC operators or application engineers. Basic function of these kits is to experiment with the electrical panel as well as the ladder diagram of CNC machines. Participants are trained to solve most of the commonly occurring issues / problems in CNC controllers. It not only involves ladder design but also involves electrical circuit design and understanding. Basic arrangements are provided to distinguish three phase and single phase power supplies. It gives participants necessary confidence and basic understanding of the electrical control panel. Primary target of the CNC Maintenance Kits is to equip maintenance engineers and CNC operators with necessary skillset to resolve most of the recurring problems in CNC machines. Mechanical slides are also provided with maintenance kits which allow participants to have hands on experience with hardware related parameters. Complete operation manual is provided along with each maintenance training kit which is designed in collaboration with OEMs such as Fanuc and Siemens. Operating manual is designed in such a way that it will guide participants to understand the basic operation and maintenance parameters of CNC systems. Electrical panel is designed with completely isolated circuits for different operating voltages with color coded cables. Check points are provided to check the voltage at different checkpoints with proper safety precautions to avoid any accident. Few of the experiments that can be carried out on maintenance kits are mentioned below: Taking System Backup Restoring System Backup Setting Backlash Limiting the speed of each axis Setting acceleration and deceleration for each servo axis Setting software limits Setting hardware limits Axis referencing Changing Servo Parameters Changing spindle parameters and incorporating encoder Understanding electrical circuit diagram and function of various electrical components used Basic single phase circuits Basic Three Phase circuits Understanding of basic components and bottle neck components (from CNC OEM such as Fanuc and Siemens) Dynamic updation of machine ladder diagram PLC ladder monitoring and understanding function of various input and output bits Understanding the electrical circuits of peripheral accessories Setting axis parameters for belt driven system, direct coupled system etc Setting spindle parameters for belt driven system, direct coupled system etc Prestigious Customers: Maruti Suzuki Capability Development Center – Manesar IGTR Ahmedabad MSME Agra IDTR Jamshedpur TRTC Patna MSME Mumbai IGTR Aurangabad IIT Delhi MSME Mumbai MSME Coimbatore

...more

sequence valves

Sequence valves Hydraulic System Test pressure of 70 Bar and continuous operating pressure of 40 Bar. Hydraulic circuits can be designed in software and the same can bedemonstrated on training kit.

...more

semi automatic lathe machine

Semi automatic lathe machine Industrial controllers from Siemens and Fanuc. Option of 8 station and 4 station production type Automatic turret.

...more

road milling machine

Road milling machine 8 Station ATC (Automatic Tool Changer) with Pmeumatic Actuation. Automatic Lubrication and Automatic Coolant.

...more

quick exhaust valve

Quick exhaust valve Pneumatic circuits can be designed in software and the same can be demonstrated on training kit.

...more

pneumatic trainer kit

Pneumatic trainer kit Pneumatic circuits can be designed in software and the same can be demonstrated on training kit.

...more

Pneumatic Timer

Pneumatic timer Online simulation and updation of PLC Programs. Aluminium Alloy mounting panel for quick mounting and dismounting.

...more

pneumatic motor

Pneumatic motor Aluminium Alloy mounting panel for quick mounting and dismounting. Pneumatic circuits can be designed in software and the same can be demonstrated on training kit.

...more

pneumatic cylinder kit

Pneumatic cylinder kit Online simulation and updation of PLC Programs, Aluminium Alloy mounting panel for quick mounting and dismounting.

...more

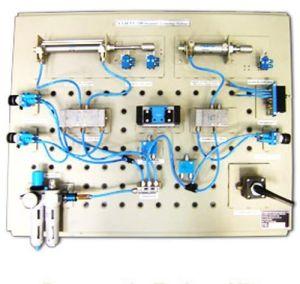

Pneumatic Control Panel

Pneumatic control panel Aluminium Alloy mounting panel for quick mounting and dismounting. Pneumatic components from Reputed brands such as SMC Festo.

...moreBe first to Rate

Rate ThisOpening Hours