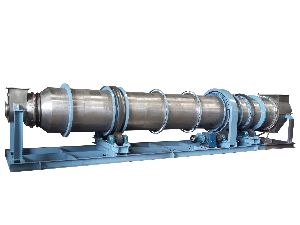

DDGS DRYER

8,000,000 Per Set

1 Set(s) (MOQ)

We are one of leading manufacturer of ddgs dryer (dry distillers grain soluble dryers). We have achieved the level of design for bellow 10% product moisture and higher syrup (dwgs) addition.our design is very different from rotary tube bundle dryer which lead more moisture contains. drying process: what is leftover in the distillation process is a nutritious mash or distiller’s grains, a very popular livestock fee.it passes trough decanter to separate fibers and thin slope, fibers directly transfer to dryer and thin slope transfer to evaporator to increase concentration up to 45% and then it transfer to drying process, mixture of decanter wet cake and evaporators thin slope (syrup) fed to our specially design dryer to get minimum moisture (bellow 10%) up to as per requirement.specifications:

Rotary Dryer

Get Price Quote

Rotary Dryers / Coolers are widely used in the Industry for drying / cooling of reasonably free flowing materials. AVM offers Customized Rotary Drying Systems with variety of Configurations. DIRECT ROTARY DRYERS & COOLER The material to be dried / cooled comes in direct contact with the drying / cooling media. The dryer comprises of a rotating shell supported on rollers / tyres and driven by means of suitable drive arrangement. Drying / Cooling media (Air / Gas) is admitted through stationary hood at one end & taken out from stationary hood from other end. Feed is admitted through suitable feeding mechanism like Screw feeder / Chute. The rotating shell is provided with specially designed material showering mechanism like Lifters / Garland Chains etc. Shell inclination & rotating speed facilitate forward movement of the material towards discharge end providing required residence time. Drying (or Cooling) takes place by heat transfer to (or from) showering material with the drying (or Cooling) media within the shell. Product is discharged from the stationary hood through suitable equipment like Flap Valve / Rotary Valve / Screw Conveyor / Chute. Air Flow Configurations : Co-Current Flow Counter-Current Flow Air Heating System Configurations : Direct Fired / Indirect Fired Air Heaters: using Liquid / Gaseous Fuels. Direct / Indirect Fired Air Heaters: using Solid Fuels, Agro Waste, Saw Dust, Rice Husk, Coal, Briquette etc. Indirect Air Heaters: Using Steam / Hot Oil / Thermic Fluid. Electric Air Heaters: using electricity. Product / Fines Recovery System Configurations : Cyclone Separators: Mono, Twin, Quadruple, Multi etc. Bag Filters: Reverse Pulsejet, Mechanical shaking etc. Wet Scrubbers – Direct Contact Ventury, Adjustable Ventury, Packed scrubbers etc. Optional Features Configurations : Feed material conditioning. Back mixing of product with feed material. Pneumatic conveying system and finish product handling. Computerized control system through PLC / DCS & SCADA. IN-DIRECT ROTARY DRYERS The material to be dried does not come in direct contact with the drying media. The dryer comprises of an assembly of two concentric rotating shells supported on rollers / tyres and driven by means of suitable drive arrangement. Feed is admitted through suitable feeding mechanism like Screw feeder / Flap Valve into the dryer through stationary feed hood. The drying media is admitted through the inner shell & travel towards discharge end & again returns towards feed end through specially designed return gas passages on the inside of outer shell. The inner shell is also provided with suitable radial lifters. These lifters along with return passages geometry is designed for showering of feed material. Shell inclination & rotating speed facilitate forward movement of the material towards discharge end providing required residence time. Drying takes place by heat transfer to the showering material by direct contact with inner shell & return passages. Product is discharged from the stationary hood through suitable equipment. Air Heating System Configurations Direct Fired Air Heaters : Using Liquid / Gaseous Fuels. Direct Fired Air Heaters : Using Solid Fuels, Agro Waste, Saw Dust, Rice Husk, Coal, Briquette etc. Product / Fines Recovery System Configurations : Cyclone Separators: Mono, Twin, Quadruple, Multi etc. Bag Filters: Reverse Pulsejet, Mechanical shaking etc. Wet Scrubbers – Direct Contact Ventury, Adjustable Ventury, Packed scrubbers etc. Optional Features Configurations : Feed material conditioning. Back-mixing of product with feed material. Pneumatic conveying system and finish product handling. Computerized control system through PLC / DCS & SCADA.

Best Deals from Industrial Dryers

Tray Dryer

52,000 - 72,000 Per Piece

1 Piece (MOQ)

ROTARY DRYER SYSTEM

Get Price Quote

The rotary dryer is one of the most common types of industrial dryer, it is a cylindrical shell usually constructed from steel plates, slightly inclined and is usually operated with a negative internal pressure to prevent dust escape. Large quantities of granular material up to particles of 10 mm or larger that are not too fragile or heat sensitive or cause any other solids handling problems are dried in rotary dryers.

Spin Flash Dryer

Get Price Quote

This consists of a horizontal agitator, which disperses the feed while it comes in contact with the hot air and gets dried. Flash dryers are used for drying of wet cakes which are sensitive to heat. There are different variations of flash dryers available depending upon the need to disperse the wet cake or pastes. These are:

Rotary Sugar Dryer

Get Price Quote

Rotary sugar dryer is a drying machine which is used to dry the wet sugar coming from batch type centrifugal machines through sugar hoppers. It is designed superbly and it feeds rotary sugar dryer by means of screw feeder in to the dryer by way of screw feeder, belt conveyor or other appropriate mechanism depending on feed properties. It is attached with hopper in which feed material is poured which further comes into screw feeder into the dryer with, belt conveyor or other suitable mechanism works as per feed properties. The rotation of drum lifts the flight to the portion of dryer and the material’s portion downs to the dryers’ portion. Material comes in touch with the hot air while it falls down. As per the feed property and the requirement of process the counter current or co current flow depends. Direct or indirect hot air generator is used to produce drying media. This rotary sugar dryer is designed with a rotating cylindrical shell with internal lifters and also fitted with two cast steel tyres and sprocket. Chain and sprocket which is coupled to sprocket helps for the rotation of shell. The final rotation of drums shall be 4-6 rpm.

laboratory tray dryer

Get Price Quote

Continuous Fluid Bed Dryers

Get Price Quote

Continuous Fluid Bed Dryers, industrial process automation, Roaster Machines

conveyor dryers

Get Price Quote

conveyor dryers, Boilers, Steam Jacketed Kettle, Tanks

Agitated Thin Film Dryer

Get Price Quote

Agitated Thin Film Dryer, Paddle Dryer, Axial Flow Pump, Liquid Extractor