Bulk Powder Weighmetric Filling Machine

Get Price Quote

1 Piece (MOQ)

beverages filling machine

Get Price Quote

Fruit juices are made from fruit pulpconcentrate artificial sugar may or may not be added to the juice extracted. The sugar syrup is prepared first in jacketed mixing tank and then it is mixed with fruit pulp, water along with other ingredients like flavor, color, preservatives etc. In the other mixing tank. This mixture is pasteurized to remove any microbial growth from it and later on homogenized to prepare a uniform blend of juice. Complete sets of fruit juice beverages and soft drinks production line: 1. Sugar syrup preparation tank 2. Fruit pulp storage tank 3. Filter press 4. Blending 5. Homogenization 6. Standardization 7. Pasteurization 8. Filling line: - automatic bottle filling line with rinsing filling & cap sealing machine in addition to the above machine, we can also offer a bottle blow molding plant which will make bottles for you from pet preform per your desired shape and size.

Best Deals from Industrial Machine

HVAC Duct Forming Machine

Get Price Quote

1 Piece(s) (MOQ)

We are offering clients our broad array of HVAC Duct Forming Machine. It is made using superior quality raw material and modern technology at our vendors’ end. HVAC Duct Forming Machine is available with us in different sizes and specifications as per the requirements of customers. Moreover, our HVAC Duct Forming Machine is sturdily constructed and gives high performance.Range : Spiral Tube former Roll forming for PDF clips Machines for rectangular ducts Duct Seamers Elbow Maker Stitch Welder Plasma Cutting Machine Swager Seamer Tube Former Flexible Pipe Machine Spiral Pipe Machine Machine for connector Flange Technical Specifications : Diameter : 125-1400mm ( 80 and 100mm on request) Material : 0, 4-1.0mm galvanized steel, others on request Coil : 1000kg/OD 1200mm, ID 480-530mm Strip width : 137mm Material speed : Max 50m/min Run of table : 4000mm as standard Power supply : 3x400V, 50Hz, 11kw Pneumatic : 6.5 bar Information Of Spiral Tube former : The TF 1400 Ultra Tubeis specially designed for the fully automatic production of seamed spiral tubes. The tube matches with the standards of DIN EN 12237 SMACNA AFNOR, BS or EUROVENT regarding accuracy and admissible pressures : Vertical, adjustable uncoiler with brake system Single corrugating unit Forming Strips for the tube productiom Flying Slitter for a cut free of burrs Siemens PLC control with touch screen and pushbuttons Ecological GLL Lubrication System

sugar mill automation machine

Get Price Quote

Our noteworthy entity is actively engaged in manufacturing, supplying, and exporting of sugar mill automation machine in India.

Evest Pick and Place Machine

Get Price Quote

•Y-axis applies dual-servo motor drive, •High Rigidity and Durability •Assorted Head Modules for Different application Needs

Semi Automatic Printing Machine

Get Price Quote

We Are Offering Semi Automatic Printing Machine, A High Precision Screen Printing Machine For Paper, Sticker Printing. It Is Suitable For Products Like Letter Head, Greeating Cards, Wedding Cards Can Be Printed With Machine. Stickers, Foils And Various Other Media Can Be Printed With High Acuracy. Features : The squeegee printing system works on imported linear block guide for extremely stable printing. Sensor is provided for controlling the printing stroke, which can be laterally adjusted to suit various print sizes. Pneumatically operated printing head lifting design provides convinient replacement of squeegee, flood bar,screens as well as easy access for cleaning. The printing Table can be Vacuum or slotted to hold jig or fixture. The flood bar can coat or pre-coat during printing minimising screen clogging. The priniting table is equipped with 3 sets of micrometric adjustment knobs for precision alignment of printing in lengthwise, lateral and angular direction Pneumatic drive, low-noise levels and trouble free performance. The screen is vertically positioned to prevent ink overflow at the sides, therefore lowering ink consumption. Rigid Screen holders for vibration free printing. Shock absorbers for vibration free stopping of suqeegee movement, longer life of Rodless cylinder. Big E.stop for operator’s safety T slot table avialable for product printing Heavy construction of base frame. Advance PLC system for reliable and consistent performance of the machine.

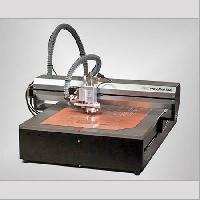

pcb prototyping machine

Get Price Quote

YL 32 workshop crimping machine

Get Price Quote

YL 32 workshop crimping machine is generally used at the hardward shop/workshop. with Die sets 14,16,19,22,26,30,34,39,45,51,63,69mm

socketing machine

Get Price Quote

Machine Operates on Solid State PLC Control With MMI Water Cooled Die Ensures high Production rate. Both ovens Temperature Controlled by PID

Cement Feeding System

425,000 Per Unit

1 Set (MOQ)

Cylinder Head Cleaning Machine

250,000 Per Units

semi automatic screen printing machines

600,000 Per unit

industrial embroidery machine

Get Price Quote

The PR1000e is the ideal machine to take your home business embroidery to the next level. It incorporates many new features which work together to enhance your productivity. It offers 10 needles for a wider range of colours, an extra large embroidery area, with easy to use embroidery positioning camera sensor, and a powerful, yet effortlessly simple, touch screen control system with built-in editing and design preview functions. PR 1000e 200mm x 360mm embroidery area High defi nition ASV LCD touch screen Advanced natural lighting system Variable speed: 400 to 1,000 stitches per minute Automatic threading 28 built-in fonts USB ports (2.01.1)

multi screw tightening machines

Get Price Quote

We efficiently carry out systematic process at every stage, to make certain that the product basket is developed as per the specified requirements. Owing to our excellent Maharashtra(India), we efficiently make on-time deliveries to the customers.

Batch Type Washing Machine

200,000 Per Piece

Cylinder Head Conveyorised Cleaning Machine

500,000 Per Piece

Rapid Prototype Machine

Get Price Quote

3D printing (Rapid prototyping of 3D object) is a process of making three dimensional solid objects from a digital model. 3D printing is achieved using additive processes, where an object is created by laying down successive layers of material. The 3d printers can be used in jewelry, footwear, industrial design, architecture, engineering and construction (AEC), automotive, aerospace, dental and medical industries, education, geographic information systems, civil engineering, and many other fields.

Cement Feeding System

Get Price Quote

This Pneumatic conveying systems offers 18 to 20 tons per hour capacity for bag & bulk cement feeding to silo. The stationary bulker is connected to twin lobe blower with necessary piping up the silo. 18 ton capacity bulker is manually feeded & pressurised to feed the cement to silos. No of silos can be feeded from one system. Dust enclosure & suctions type dust collector systems are also available as optional. As system electrically consumption starts after manual feeding only. This system is exclusively designed to have practically possible & suitable feeding rates at lower connected power reduces the operating cost marginally.

radial arm belt feeding systems

Get Price Quote

We are offering radial arm belt conveyor for inline compartment plant 600 to 1000 wide & 15000 mm to 22000 mm long, capacity – 100 to 300 tph.

liquid filling machines

Get Price Quote

Avail from us well designed Liquid Filling Machines at reasonable prices. We are counted among the top Juice & Pulp Filling Machinery Manufacturers, Suppliers, and Exporters in India. The Can Filling Machine is known for its easy operations and durability. We provide Rotary Pump Filler as per the requirements of the clients in the minimum time possible. Highlights Well designedEasy to useLong working lifeResist corrosion Suitable For Filling Soft drinksFruit PulpsJuicesShampoos

Roll to Roll

Get Price Quote

Machine : roll to roll heat transfer machine, model : roll to roll heat transfer machine 72, company : gn mechanical works, country of origin : india, faridabad.

Manual Torsion Spring Testing Machine

Get Price Quote

Industrial Hemp Seed Shelling Machine

Get Price Quote

Industrial hemp seed shelling machine is an improved hemp seeds processing plant and this processing plant is capable of completing impurity removing, seed dehulling, kernel peeling, shell and kernel separating and re-separating for the hemp seed in one operation. Industrial-hemp-seeds shelling and separating unit technical data: model pvgtfma1200 power 14.59kw440v perfect kernel rate ???90% (the broken kernel is less than ½ whole one) non-sorted kernel rate ???2-5% capacity 0.5-0.8th (differing by raw materials that is to be processed ) covering area of the whole unit 14.4×2.8 m installation height 4.1m weight 5t

Industrial Parts Cleaning Machines

Get Price Quote

Industrial Parts Cleaning Machines

Pouch Filling Machine

Get Price Quote

We are offering pouch filling machine multi component, multi recipe batching systems can be supplied with any number of components and recipes. Depending on the complexity, the appropriate controller or plc is selected. The systems can be manual or semi automatic or fully automatic, as per customer's requirement. Various features such as relay logic, mimic diagrams, emergencysafety interlocks, data management, automatic ticket printing, inventory correction, status reports, history charts, scada, etc. Can be given in these systems.

Light Duty Lathe Machine

Get Price Quote

Full Machine Size (LXWXH) 1200 X 600 X 500 Machine Centre Height 8 inch Max. Turning Dia 100 mm Spindle HP with VFD 3 HP AC Servo Drive & Motor 1.3 Nm Spindle Bore 38 mm Spindle Speed Max. 3000 Spindle Nose A25 Repeatability 0.04µ Lubrication Automatic Ball Screw (Hiwin) Ø 25 CNC Controller Mach3 Siemens* Coolant Automatic 4 Station Square Tool Turret 130 Optional Hydraulic Chuck Ø 165 Optional Max User College Trainer Toolroom Production

Multihead Weigh Filling Machine

Get Price Quote

The Multihead Weigh and Fill System is a great step to take your business from hand operation to automation. Your bulk product is placed in the supply hopper at the top of the machine. The Weigh Filler Machine uses an electromagnetic vibratory feeder to move the product from the supply hopper to the weigh hopper where it is weighed. When the target weight is reached, the Controller stops the feeder, and the weigh hopper opens automatically or with the foot switch to dump your product into your container. A new fill cycle is started and your filled bag may now be sealed.These are mostly used in pharmaceutical filling & food filling as a filler or dispenser.

Paper Cup Making Machine

Get Price Quote

Matching up with the ever increasing requirements of the customers, our company is engaged in providing Fully Automatic Paper Cup Making Machine.

Industrial X Ray Machine

Get Price Quote

Bosello High Technology S.R.L was formed in GENERAL CASTING RADIOSCOPIC EQUIPMENT 160 KV, 225 KV or 320kv in a different size cabinet HIGH-SPEED RADIOSCOPIC INSPECTION SYSTEM FOR LIGHT ALLOY WHEELSand today it is one of world's leading manufacturers of Industrial X -Ray Inspection systems for NDT Controls.The WRE THUNDER 3 equipment is the fastest solution for the on-line inspection of alloy wheels.

Sand Blasting Machine

Get Price Quote

Yash Blast Abrasive blasting machine can be fitted in variety of versions, with various kits and accessories, in order to meet exact requirement of the customer. Sand Blasting Machines are used for various applications like cleaning of moulds, putting Grains on the moulds, preparing surface for painting, PTFE Coatings etc. Yash blast abrasive machines are manufactured to the International standard and are used on production site through out the country. The machines comes in ready condition to be used, only a compress air connection to be priored. The medium used for Blasting is collected in the machine and can be used for many times and Exhaust Blowers provide at the top of the machine with filtering system to give clear Exhaust Air all models are equipment with concave head for easy filling, with automatic pop up valve. All vessels are tested at high pressure as per international standard the conical bottoms ensure and easy flow of abrasive to the metering valves. The inspection trap is period for access to the interior part of the vessels. All welding are performed with the help of rotator at position and thoroughly checked and documented, as per the procedure qualifications all the vessels are fabricated in accordance with ASME section 8(Roman) and with pollution control norms Hydraulic as per the Fabrication there for granted the highest level of performers.