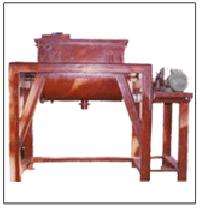

die coat mixing unit

245,000 Per Piece

1 Piece (MOQ)

printing ink mixer

Get Price Quote

This important environmentally-responsible shift coincided with exciting developments of new functionalities as a response to changing customer needs. Now faced with a growing demand for specialty and high value-added coatings, manufacturers are taking a closer look at their processing methods, particularly the mixing and milling steps

Best Deals from Industrial Mixers

Ribbon Blenders

Get Price Quote

Ribbon Blender are mostly used by Chemicals, Plastic, Pharmaceutical, Paints and food industries. The Ribbon Blender does homogenous mixing of powder and semi-wet material of different densities. The ribbon blades of different designs are used to suit the need of different materials. The Blender consists of a Semi-cylindrical shell inside which rotates a Shaft fitted with spiral inner and outer ribbons.

Dual Shaft Mixer

Get Price Quote

The Dual Shaft Mixer includes an Anchor agitator and a High Speed Disperser. The anchor feeds product into the high speed disperser blade and ensures that the mixture is constantly in motion. The anchor can be provided with scrapers to remove materials from the interior vessel walls to enhance the heat transfer capabilities of the mixer. Both agitators are available for variable speed operation.

Paddle Mixer

200,000 Per Piece

1 Piece (MOQ)

Ribbon Blender

Get Price Quote

The Ribbon Blenders offered by us are technologically designed to make them useable with dry materials, nevertheless, liquid and gas stream can be added. In this blending process, the outer ribbon pushes the materials from both ends to the center and at the same time, the inner ribbon pushes material from center to both ends. Features: Low maintenance Excellent functionality High strength

VSEL Anchor Agitator

150,000 Per Piece

1 Piece (MOQ)

paint mixing machine

Get Price Quote

We are known for providing only flawless range of products as we store the entire lot under safe environment in our spacious warehouse. Moreover, the lot is regularly checked by our experts. Ours is the known organization deeply ingrained in the Pune(India) and make sure to reach any destination with ease. Features: High-performance Robust construction Easy operations & maintenance

Industrial Mixers

Get Price Quote

Stainless Steel Mixing Tank

Get Price Quote

1 Piece (MOQ)

electric & pneumatic operated stirrer

15,000 - 5,000,000 Per Piece

1 Piece(s) (MOQ)

we are one of the preeminent fabricator & supplier of electric & pneumatic operated stirrer, agitators & mixers in the market. Our products are made up of superior quality raw materials; make them extremely sturdy and long lasting. We fabricate some specialized stirrer/agitator as per specification and also source stirrers / agitators from the best known manufacturers in the industry. The product is used in various industries and receives appreciation for its close tolerances, easy operation, less maintenance, and corrosion resistance. We offer stirrer/agitators in various sizes and are open to customization as per the specifications provided by the customers. attributes : suitable for mixing paints and liquids using variety of air & electric motor no danger of fire maintenance free use. compact and lightweight reduction of gear to increase torque low-speed revolution ensures that no paint is denatured agitator impeller & shaft moc: aluminum, ms, ss and many more as per requirement & fluid properties. variable speed agitator available vane type & bearing type air motor with grounding cable for static charge disposing safe operation models : gravity cup suction cup hand operated stand mounted single arm mounted double arm mounted and many more application area : paint shop preparation tanks pharmaceutical industries dyes adhesives chemical preparation tanks etp plants abrasive materials water based paint melamine high solid metallic & non-metallic products viscous material

Ribbon Blender

34,500 - 156,000 Per Unit

1 Unit (MOQ)

Powder Mixer

Get Price Quote

We meticulously pack the entire lot for ensuring safe and secure deliveries across the boundaries. We stock our product for wholesale distribution and supply as we have state-of-the-art storage facility along with the most advanced inventory management system and upgraded machines.Advantages : Dramatically reduces process times Produces consistent batches Eliminates ladder climbing Is fully customizable: sizes, configurations, and options 100kg Approx Price : Rs 1.4 Lakh / No

Paddle Mixer

Get Price Quote

Mixer conveyor is known in the industry by various names such as Paddle mixer, Ash Mixer, Pug Mill, Unloader etc. DEMECH Mixer Conveyors find applications in many industries. This equipment is the perfect solution for pollution control as it effectively blends dust - recovered from ESP, Mechanical collectors, bag houses, Silos etc.- with various liquids, thus allowing transport but effectively controlling the particulate matter escaping into the air.

Agitator Storage Tanks

Get Price Quote

Leveraging on our experience, we, as a supplier of Agitator Storage Tanks have placed ourselves in the upper echelons of the industry. We are strongly backed by a well maintained and managed storage house wherein we store our products for meeting urgent and massive requirements of the buyers. Applications : ETP Food Ceramics Winery Petroleum Biochemicals Pulp & Paper Pharmaceutical Detergent Plants Chemical processing Features : Heavy duty bearings Rugged cast or fabricated housing Custom built designs to suit specific applications Efficient blade profiles reduce energy requirements Dynamically balanced to ensure vibration-free operation Accommodates standard packing or single or double mechanical seals Simplified design ensures quick, easy and inexpensive installation and maintenance

Ribbon Mixer

Get Price Quote

We are the prominent manufacturer of a wide range of Ribbon Blender. The offered range is manufactured using the finest grade raw material and latest techniques. Apart from this, these blenders are quality tested on well-defined parameters in order to ensure their flawlessness. Client can avail the offered blender from us at the most reasonable prices.

Mixing Tanks

Get Price Quote

1 Piece(s) (MOQ)

Our industry is pharmaceutical, cosmetic, food, beverage, chemical or petro-chemical, efficient mixing is at the heart of most successful processes. Often operating continuously and under arduous conditions it is important to select the correct mixer for the job.Our vessels can be supplied with mixers manufactured from our own range of designs, customer specifications or from specialist mixer manufacturers.From small portable to large complex units, We can supply mixers as: Top entry Side entry Clamp-on Gate stirrers Anchor Multi impellor Magnetic (hygienic) High Shear Contra-rotating Dual speed Variable speed Scraped wall Mixers can also be supplied with motorized mechanical or hydraulic lifts.

Inline Homogenizer Mixer

255,000 Per Piece

1 Piece (MOQ)

Electricity Mixing Reaction Tank

Get Price Quote

static mixers

Get Price Quote

SLIM technology enables you to wet out powders instantly. The SLIM system sucks solids directly into the high shear rotor-stator where they are wetted out and dispersed into the liquid stream.

Twin Shaft Disperser/ Dissolver

Get Price Quote

One Piece (MOQ)

Best Performance of Applications : Premixing Dispersing & Mixing of High Viscous Material. All type of Low, Medium & High Viscosity Liquid / Pharmaceuticals / Chemicals / Floor Coatings / Colorants / Automotive Coating / Industrial Coating / Aerospace Paints / Pigments / Ink / Solids / Wood Coating / Decorative Coating / Food processing / Cosmetics/ Ceramics / Adhesives / Textile / Plaster / Polyurethane Coating / Stucco / Resin / Marine Coating /Dyestuff Chocolate Paste etc Industries.

Powder Mixing Machine

Get Price Quote

We are offering powder mixing machine process: powder of various elementscompounds such as cobalt, tin, silver, tungsten metal , tungsten carbide etc. Are weighed along with requisite diamond grit. These are then put in stainless steel jarscans which are then loaded on the mixing machine. Mixing machine when put on runs for predetermined time through programmable timer planned which runs the machine. It allows all the powders put in required proportion depending upon the bond selected to uniformly mix and become amalgamated as required for further process of compacting and hot sintering. machine specification: model : tmma h.p : geared motor , 1 h.p , 3 phase , 415v , 50 hz. Capacity : 10 kgs in four jarscans. Machine supplied : with or without programmable timer. Appx. Dimension : 700 l * 800 b* 1200 h in mm. special programmable timer : machine is supplied with programmable timer and electric circuitry having following features: 1) on delay 2) off delay 3) cycle on 4) cycle off 5) auto reverseforward with pause with 4 set timers. 6) multiple timer range : 1-9999 secminhours. 7) battery backup for power failure-for programmable setting only. machine would continue as per the pre-set cycle after power is restored

Mixing tank

Get Price Quote

We are one of the leading manufacturers, suppliers, traders and exporters of a tank. These tanks are developed and designed using high grade raw material in compliance with industry laid norms and guidelines. All the tanks offered by us are widely applauded by our valuable clients for their excellent features such as high durability and high tensile strength.

Ribbon Blender

Get Price Quote

We are offering ribbon blenders, which are available in different speculations depend upon application. We are a renowned ribbon blender manufacturer, exporter, and supplier from india. Our ribbon blender is available with u-shaped horizontal trough and double helical ribbon for high speed and effective rotation. It blends powder in horizontally and vertically as well. Our ribbon blender is suitable for various cohesive powders and can easy handle different kind of densities. available in : liters : 100 to 5000 material : stainless steels (varied grade) model : gmp (optional) components : electrical motor worm reduction gear belt drive mixing stirrer discharge valve(centrally located) & top cover cooling or heating jacket( optional) applications : industrial mixers pharmaceutical mixers industrial pharmaceutical mixers

Mixer Ribbon Blender

200,000 Per Piece

paste mixer

Get Price Quote

The UNIK heavy duty Sigma Paste Mixer is very different from the widely available mixers which look similar. UNIK mixers are superior and rugged. UNIK mixers have a solid stainless body unlike similar mixers which have SS lining. The tilting arrangement of UNIK mixers is far superior and very convenient to use. UNIK mixers have strong SS lids and not the light weight MS lids which corrode easily. UNIK mixers offer substantial savings to the user due to ‘no downtime cost’.

Paint Agitator Tank

Get Price Quote

The paint tank and agitators produced by Sumake are widely used in food, pharmaceutical industries and chemical industries. They are given a sturdy body to give excellent outputs.

Static Mixer With Luer Lock & PVC Needle for Dispensing

500 - 1,000 Per piece

10 Nos (MOQ)

Static Mixer With Luer Lock & PVC Needle for Dispensing

Paddle Mixer

Get Price Quote

We are the prominent manufacturer & supplier of a wide range of Paddle Mixer. The unique paddle design is ideal for mixing solids or liquids of various particle size, density and viscosity. The gentle scooping action is ideal for blending fragile ingredients such as nuts or fiberglass strands. Paddle mixers work effectively when filled to as little as 20% of rated capacity, thus allowing flexibility of batch sizes. Paddle style agitators allow easier access for cleaning between batches.

continuous mixers

Get Price Quote

Continuous mixer with processing performance of the form 3 ° - 8 t / hThe outreach center equipment rack to middle molding material outlet is the standard version of 3500 mm. Furthermore, the continuous mixer at the customer with radii of 3100mm and 4100mm are available. Scope of Application The continuous mixer CM 3-8 series are used for the continuous preparation of molding materials in the no-bake process on Furan, Phenol or Polyorethanbasis. The continuous mixer CM 3-8 are used for the production of cores or molds. Special Features Proven mixers for homogeneous preparation of molding materials with high wear resistance. Maintenance-friendly design by opened lateral troughs with quick release buckles. High level of safety through safety switches are at the trough shell closure. Equipment of mixers with wear shells with long service life. Mixing auger with adjustable mixing blades blanks and screwed mixing flights running records as wear protection. Overflow records are a wear-resistant white cast iron with very high durability. The mixing blade inserts can be easily replaced. Two articulated continuous mixers are equipped as standard with a mixer Sandzuführschnecke. The hinges are rotated manually and are braked individually. For quick sand change, the sand is fed to the mixer via an enclosed conveyor belt.. The pivoting of the continuous mixer is done manually by the operator at a height adjustable swivel bracket to which the control box is mounted. The control box is equipped with switches for pivot brakes, 5-step recipe switches, technological stop, switch for fat and lean mixture and the switch for mixed sizes. The dosing of the regrind / new sand is via electro-pneumatic control Sanddosierschieber, which are mounted on supply pipes or bunker runs. The adjustment of the amount of sand is continuous and takes place at the control cabinet without manual adjustments. Frequency-controlled dose over Spindeldosierpumpen Metering resin and hardener into the mixer. Spindeldosierpumpen is a volumetric dosing, which operates with high dosing. This metering pumps require very little maintenance and are wear-resistant. The dosing pumps can be supplied from the customer's own loops or are part of a Gebindelagerdosiereinrichtung. Measurement of sand temperature in the sand supply and temperature-dependent hardener Binder and hardener feed monitoring Binder and hardener supply monitoring and control (optional) PLC control the plant with recipe entries and recipe storing the cabinet and demand on the control box. Programs for review by sand and binder components.