Agitators Tanks

Get Price Quote

Anchor-type agitators are principally designed to mix highly viscous products and non-Newtonian fluids, i.e., they lack a certain degree of viscosity because it depends on the temperature. These agitators can be mounted in tanks with rounded or conical bottoms.

atta mixing machine

Get Price Quote

Single drive Dough Kneading / Atta Mixing Machine. Suitable For Besan Atta, Maida, Chapati, Khakara, Chakli Etc.

Best Deals from Industrial Mixers

MBC Double Cone Solids Blender

Get Price Quote

The double cone blender is used to produce homogeneous solid-solid mixture. Mixing is a common process step in the manufacture of products for industries such as healthcare, food, chemical, cosmetics, detergents, fertilizers and plastics.Examples of materials or substances mixed in this way include pharmaceutical granules, semolina flour, seeds, starch, coffee beans and ground coffee, cocoa, chocolate flakes or granules, powdered milk, baby food, preparations to make dehydrated soups and creams, leaf waxes, detergent granules, soap flakes, artificial fertilizers, plastic in powder, ground or pellet form, fibreglass, etc. Operating principle The main body of the blender consists of two cone-shaped sections welded at their bases to a central cylindrical section. The axis of rotation is perpendicular to the cone axis and passes through the cylindrical section. The driving motor is located at one of the two lateral supports holding the blender body.The solids are introduced into the blender through the loading aperture. In this type of blender, mixing takes place axially, as a result of the powder moving through the different sections. Mixing is thorough but it depends on the rotating speed.The mixture is discharged through a hermetically closing butterfly valve which can be operated manually or automatically.The unit is provided with a guard rail with electrical safety to prevent the operator from accessing it when in operation. If anyone should gain access to the unit, for safety reasons, the operation will cease. Design and features The series consists of 6 models with a total capacity of 160 to 4200 litres and a useful capacity of 65% of the total.This blender is especially designed for sensitive mixtures with risk of breakage where the generation of dusts is to be avoided.Mixing times vary between 5 and 20 minutes depending on the mixture.The interior of the blender incorporates a cone mounted on the pivot axis on both sides. This system eliminates the formation of dead spaces and facilitates gravity discharge.The unit is manufactured in AISI 316 (EN 14404) quality for all parts in contact with the product and AISI 304 (EN 14301) for the supports and the rest of the equipment. The internal and external surfaces have a bright polished finish. Due to the polished surface and absence of edges or corners, the unit can be easily cleaned either manually or automatically with CIP system.The unit incorporates a guard rail with electrical safety, according to EC safety standards. Materials Parts in contact with the product AISI 316 (EN 14404)Structure and other metal parts AISI 304 (EN 14301)Internal finish Bright polishExternal finish Bright polish Options This unit allows the incorporation of a liquid spray system to introduce liquids in spray form during the process. The injector is connected to the spray nozzles by means of a rotary system and is fed with additives from a pressurized tank or by means of a variable displacement pump at constant pressure.The automatic stop positions are: loading, discharging, and sampling. Before stopping at one of these three positions, the system performs a cycle which slows down the mixer in order to reach the stopping position with the highest possible accuracy and remains halted at that point.The unit can be equipped with an automated loading system for introducing powders and granules into the blender body by means of a vacuum unit with self-cleaning hoses. It prevents creation of dust.The skid can also be provided with a complete monoblock vacuum unit with liquid ring pump.It is possible to install an automated vacuum discharge system. It includes a product receiving hopper with an automatedself-cleaning filter; as well as a control panel for the unit.The loading/discharge can be carried out with pneumatically actuated retractable hermetic bellows. This system and the vacuum loading/discharge can be combined.

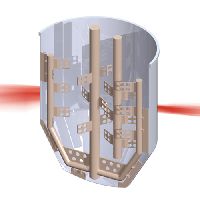

Industrial Agitators

Get Price Quote

Anchor-type agitators are principally designed to mix highly viscous products and non-Newtonian fluids, i.e., they lack a certain degree of viscosity because it depends on the temperature. These agitators can be mounted in tanks with rounded or conical bottoms.

Chemical Agitators, Stirrers

Get Price Quote

We are offering chemical agitators, stirrers, we manufacture agitators that are designed in accordance with the clients requirements. All these agitators are used across several industries. Made using premium quality of materials procured from reliable sources all these agitators not only withstand excessive wear and tear but also can be installed with great ease. All these agitators require high precision and are also flawless in performance.

Flour Mixing Machine

28,950 - 85,950 Per piece

1 Unit (MOQ)

Pneumatic Drum Stirrer

Get Price Quote

01 Piece (MOQ)

Jacketed Reactor

Get Price Quote

We are offering Jacketed Reactor in the market. Jacketed Reactors, offered by us, have a sturdy construction, and high efficiency. Jacketed Reactors are used for carrying out a number of chemical reactions. These Jacketed Reactors have a jacket on them, and are designed in such a way to ensure that chemical reactions inside it proceed efficiently.

Mixing ribbon blender

Get Price Quote

Ribbon Blender comprises of a U-shaped horizontal trough and a specially designed Double Helical Ribbon Agitator rotating within. Ribbon Blenders are based on a proven agitator construction that provides a triple mixing action ensuring fast, efficient blending. An alternate design is the paddle agitator. A ribbon agitator consists of a set of inner and outer helical agitators. The outer ribbon moves materials in one direction and the inner ribbon moves the materials in the opposite direction.

Mixing Tanks

Get Price Quote

Dhruv Fabrotech are highly engaged in providing a high-quality range of Mixing Tanks. Features: Rigid design Hassel free functioning Long working life Specification: Power 230 VAc Mixing and Diluting Agitation with Geared motor Level Indication Simple in use Easy to Align 60 lits

FMC-19

Get Price Quote

- Wind Tunnel Apparatus - For Educational Training

Chemical Mixing Machine

Get Price Quote

D.K.K. Services are immersed in offering a world class consignment of Chemical Mixing Machine. Features: Customized Reliable Fine finish Tough construction Durable

fluid agitator

Get Price Quote

Thus the shear stresses and strain rates vary greatly throughout an agitated liquid in a tank. As the viscosity of the fluids to be mixed increases, the physics fluid mechanics change from that of turbulent flow (like in liquid agitators) to that in which viscous drag forces dominate. Additionally, some fluids exhibit Non-Newtonian behavior – their viscosity cannot be designated by a single coefficient. Mixing of such fluids requires special heavy duty agitators. As the dynamic viscosity of a Newtonian liquid is independent of shear at a given temperature, its viscosity will be the same at all points in the tank. In contrast the apparent viscosity of a non-Newtonian liquid varies throughout the tank. This in turn significantly influences the mixing process. For shear thinning liquids, the apparent viscosity is at a minimum in the immediate vicinity of the agitator. The progressive increase in the apparent viscosity of a shear thinning liquid with distance away from the agitator tends to dampen eddy currents in the mixing tank. In contrast, for shear thickening liquids, the apparent viscosity is at a maximum in the immediate vicinity of the agitator. In general shear thinning and shear thickening liquids should be mixed using high and low speed agitators respectively. Wherever possible, the movement of the entire contents of the agitator vessel should be avoided as rapid movement tends to segregate the components due to centrifugal forces.

Chemical Mixer

400,000 - 600,000 Per Piece

Ribbon Blender

250,000 - 270,000 Per Piece

Tank Bottom Mixer ME 6100 ph

Get Price Quote

Tank Bottom Mixer ME 6100 ph, Flexible Impeller Pump RF

Vacuum Mixer

Get Price Quote

Vacuum Mixer, Magnetic Dental Articulator, dental lathe

mixing vessels

Get Price Quote

mixing vessels, Automatic Liquid Filling Machines, Bottle Washing Machines

Paddle Mixer

Get Price Quote

Paddle Mixer, Filter Bag, industrial fan

Blender

Get Price Quote

Blender, Mixer, Pumps, Valve

Ice Cream Churner

Get Price Quote

Air Handling Unit Maintenance Service, Water Chiller Maintenance Service

Nauta Mixer

Get Price Quote

Nauta Mixer, Metal Trough Belt Conveyor, pollution control systems

Ice Cream Batch Mixing Machine

Get Price Quote

Natural Ice Cream Mini Plant, Warmer Popcorn Machine, Kettle Popcorn Machine

Nauta Mixer

Get Price Quote

Nauta Mixer, Pan Type Mixer, weigh feeders, Bagasse Feeder, Belt Weigher

ribbon blender machine

Get Price Quote

Mechanical Conveyors, automated conveyor systems, Cleated Conveyor

Propeller agitator

Get Price Quote

Propeller agitator, Nano Filtration Plant, Bio Filter, drum scrubber

Jacketed Reactor

Get Price Quote

Rotary Pump, mechanical fine bar screen, Sluice Gate, Stainless Steel Vessel

Industrial Agitators

Get Price Quote

Industrial Agitators, Pumps

anchor agitators

Get Price Quote

anchor agitators, emulsifying mixer