Vsel Hydrofoil Agitator

10,000 Per Piece

1 Piece (MOQ)

Mixer Ribbon Blender

200,000 Per Piece

Best Deals from Industrial Mixers

Ribbon Blender

Get Price Quote

Double Cone Blender

Get Price Quote

We are a Manufacturer, Exporter and Supplier of Double Cone Blender from India. Our Double Cone Blender is a high performance machine, also known as versatility used for mixing dry powder and granules equally and extensively used in industries like pharmaceutical, chemical, food, and cosmetic products etc. Our Double Cone Blender is perfectly welded, ground, and polished internally (mirror finish) and externally (matt finish). Components : Cylindrical shell Two conical frustumsButterfly valve Robust stand with bearing blocks Gear box along with motorControl panel board Safety railing Specifications : Manual rotating facility along with hand wheel for inching. The same facility is provided with SS cover & limit switch in 200 Kg and above model Available with Two nos. of safety rods at backside, option for left and right hand usersOne shaft with 04 nos. of fixed buffels with mirror polished provided inside the cone Polished cone polished with matt and mirror polish externally and internally All moving parts covered with SS304 coversQuality safety guard made SS304 pipes located in front of the m/c with limit switchPanel manufactured using SS304 material, available with facility of three-phase indication .i.e. D.O.L. Tarter, Digital Timer, and Amplify MeterLeft side drive or with right side drive option as per the need Worm reduction gear for speed reduction in blender Food grade rubber gasket will be used on both ends of cone as well as in butterfly valveGeneral body made up form of SS304 and finely polished to the matt / mirror finish as per the demand of the clients in GMP Model. Safety guards and covers fabricated of SS304 in GMP ModelHand wheel is available manual tilting of cone.

Ribbon Blender

34,500 - 156,000 Per Unit

1 Unit (MOQ)

High Viscosity Dispensing Equipment

100,000 - 5,000,000 Per Piece

1 Piece(s) (MOQ)

We are offering high viscosity pump dispenser that is appropriately designed for transferring, extruding and spraying of sealant, greases, and many other high viscous adhesives. Our pump dispenser does not contain any seal pump hence guarantees leakage free operation. Used for single two components and three components material. salient features of our high viscosity pump dispenser : conveniently mix thematerials at the tip of gunhas static mixerensure leakage free operationsuitable for glue, dyes resin, etc.robust pumpflexibleanti-corrosiverequire zero maintenancecost effectiveused for single two components and three components material applications : automotive & auto – ancillariesceramics industryfoundry industryconstruction industryleather industrylocomotive & earth moving industrypharmaceutical industrysolar power industrysteel industrywind power industry.

Drum Blending Machine

Get Price Quote

We offer wide range of mechanical Stirrer machines for mixing purpose of different types of liquid with different range of densities, Viscosities and with different specifications. We also provide Up and Down Movement machine for Stirrer to make convenience to change the drums/ Barrels within short period of time. The Up and Down movement of Stirrers is control pneumatically with high standard materials.

Mixing Agitator Tank

Get Price Quote

Food Process Mixing Tank

Get Price Quote

dry blenders

Get Price Quote

The food industry is the main end user of most Ross Ribbon Blenders. Common applications include coffee, spices, food coloring, flour, sugar, cake and bread mixes, frozen vegetables, salsa mixes, snack foods and tea blends.

Plastic Static Mixer

200 - 10,000 Per Nos

Ribbon Blender

Get Price Quote

1 Piece (MOQ)

Mixing Tanks

Get Price Quote

1 Piece(s) (MOQ)

Our industry is pharmaceutical, cosmetic, food, beverage, chemical or petro-chemical, efficient mixing is at the heart of most successful processes. Often operating continuously and under arduous conditions it is important to select the correct mixer for the job.Our vessels can be supplied with mixers manufactured from our own range of designs, customer specifications or from specialist mixer manufacturers.From small portable to large complex units, We can supply mixers as: Top entry Side entry Clamp-on Gate stirrers Anchor Multi impellor Magnetic (hygienic) High Shear Contra-rotating Dual speed Variable speed Scraped wall Mixers can also be supplied with motorized mechanical or hydraulic lifts.

die coat mixing unit

245,000 Per Piece

1 Piece (MOQ)

Beverage Blending Equipment

Get Price Quote

Dual Shaft Mixer

Get Price Quote

The Dual Shaft Mixer includes an Anchor agitator and a High Speed Disperser. The anchor feeds product into the high speed disperser blade and ensures that the mixture is constantly in motion. The anchor can be provided with scrapers to remove materials from the interior vessel walls to enhance the heat transfer capabilities of the mixer. Both agitators are available for variable speed operation.

Agitators

Get Price Quote

Agitators are used for mixing of fluids, suspend solid particles in fluids, disperse gases, emulsify liquids and even enhance heat transfer between a fluid and a solid surface or increase mass transfer between phases. Detailed Description There are differnet types of agitators. They are either of stirred tank type in which mechanical motor driven stirrers are provided or of air lift type in which no mechanical stirrers are used and the agitation is achieved by the air bubbles generated by the air supply. The mixing of liquids or solids or any mixture within a container is achieved by agitator, which consists of a motor that have a fixed sparge ring for circulating liquid.

beverage mixing tank

Get Price Quote

Nauta Mixer

Get Price Quote

In Nauta Mixer, the blending screw orbits the conical vessel wall while it turns and gently lifts material upward. The materials are then thrust at the uppermost batch level towards the center of the vessel and then move slowly back down the center while mixing with materials being moved upward by the orbiting screw. Advantages: Gentle blending action is ideal for friable or shear sensitive materials. One blender can be used for a wide range of batch sizes, ranging from as small as 10% of the rated capacity. Nearly 100% of the blended materials are discharged through the bottom valve after completion cycle. Use nearly 50% less power per unit being blended. Less floor-space and are ideally suited to multi-story facilities.

Industrial Blender

Get Price Quote

Industrial Blender is used to blend a wide range of substances used in different industries including the chemical, food, pharmaceutical, plastic and mineral industries. Our range of industrial bender includes Ribbon Blender, Double Cone Blender and Conical Blender. These are mainly used to blend different materials using different types of blades to make an excellent quality homogeneous mixture. Our offered industrial blender is available in various specifications, depending on the material movement, mixing efficiency and ease of cleaning in various batches. This range is designed and developed using premium quality components and contemporary technology to meet various existing industrial quality norms.

Nauta Mixer

Get Price Quote

Ribbon Mixer

101,000 Per Piece

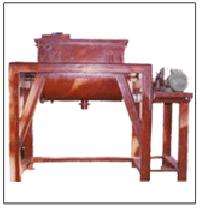

Sand Muller

120,000 Per Piece

Double Shaft Paddle Mixer

500,000 Per Piece

Inline Mixer

Get Price Quote

Be it online or cash deposit, the financial operations are carried out only under the stern management, supervision of professionals. To make our payment procedures highly secured, we make use of the leading technologies to avoid any fraud. Our range of products is manufactured under the administration of qualified quality control executives by using optimum supplies and ultramodern technologies.

Pneumatic Stirrer

32,000 Per

Ribbon Blender

Get Price Quote

Ribbon Blenders

Get Price Quote

Ribbon Blender are mostly used by Chemicals, Plastic, Pharmaceutical, Paints and food industries. The Ribbon Blender does homogenous mixing of powder and semi-wet material of different densities. The ribbon blades of different designs are used to suit the need of different materials. The Blender consists of a Semi-cylindrical shell inside which rotates a Shaft fitted with spiral inner and outer ribbons.

Industrial Stirrer

Get Price Quote

We are offering a wide range of industrial stirrer which is customized as per the specifications of our clients. These possess blades for mixing of liquid syrups, and paste type substances with blades which can later on b easily taken out of the bottle. Adding on, the jacketed arrangement for heating is provided to stirrer vessel if required.

static mixers

Get Price Quote

SLIM technology enables you to wet out powders instantly. The SLIM system sucks solids directly into the high shear rotor-stator where they are wetted out and dispersed into the liquid stream.