Vibratory Bowl Feeder With Elevator

300,000 Per Piece

1 Piece (MOQ)

Condom Bowl Feeder

180,000 Per Piece

1 Piece (MOQ)

Best Deals from Ingredient Feeder

Fully Automatic Dust Feeder

Get Price Quote

Features : This machine is an essential part of any filter testing or R&D laboratory. So any filter manufacturing company needs this machine in their quality lab. It is an in-line dust feeding system which accurately feeds the dust as per the set feed rate during the testing of air filters. It has wide range for feed rates : 20 g/min to 150g/min. ( can be customized according to customer’s requirements) Low % error, below 2% Works based on advanced system using servo motor, servo motor drive & dedicated electronic controller. Whole system is mounted on electronic balance & in continuous close loop which results in highly accurate feed rate. Special drain mode is provided to empty the hopper quickly. A machine with low maintenance & easy to operate.

Nc Servo Feeder

100,000 - 500,000 Per Unit

2 Piece (MOQ)

Vibratory Bowl Feeder

30,000 - 200,000 Per Piece

1 Piece(s) (MOQ)

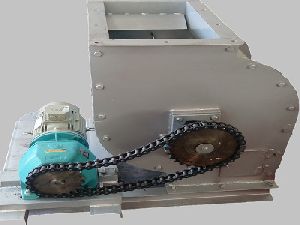

ROTARY FEEDER

Get Price Quote

We, Mukti Enterprises, under the efficient leadership of Mr. Sagar Hunalli, have the primary aim of delivering optimum satisfaction to our clients and also develop a fruitful, long standing relationship with them. We manufacture and supply Best Quality Rotary Airlock valves which are closest to perfection as far as the quality standards and the specifications of the clients are concerned.

Vibratory Bowl Feeder

45,000 - 175,000 Per Piece

Vibratory Bowl Feeder

industrial feeders

Get Price Quote

Owing to our state-of-the-art manufacturing unit, we are offering superb quality industrial feeder. By keeping track of current market development, we manufacture this feeder using well-tested components and high-end technology. Apart from this, our quality inspectors perform a series of tests on this feeder ensuring its high efficiency. Also, we offer this feeder in various configurations, so as to meet clients' different requirements. Features : efficient functionality low operational cost reliable performance

Rotary Bagasse Feeder

Get Price Quote

Electro-Magnetic Vibratory Feeder

49,000 - 50,000 Per Set

Automatic Weigh Feeder

Get Price Quote

We are offering weigh feeder indicator the d2 weigh feeder controller is a compact and rugged instrument specifically designed to operate under tough operating conditions normally occurred in conveyor belt installations. It is very simple to use, and is very user friendly. It has many user selectable options, so that it can be used for any application, for any capacity, simply by selecting the desired units and full scales. The alarms can also be set by user at desired values, which activate a relay, whose contacts can be used for further annunciator or motor control actions. The most important feature of this weigh feeder controller is that this set of 2 compact panels (belt weigher indicator & motor control panel) display the flow rate, totalized flow and the set flow rate, as well as control the flow rate locally. Of course, if required, the flow control panel can also be fixed at a remote location (say a control room). Also, in case of any fault in the belt weighter indicator, the same can be disconnected from the motor control panel, while still keeping the conveyor operational in manual mode!. Some of its salient features are salient features: full software calibration stainless steel weatherproof housing user selectable units for flow rate (tph or kgs) user selectable units for total flow (kg or t) provision for high weight, low flow & out of range alarms provision for 4-20 ma or 0ã¢â�¬â��510 vdc output, proportional to flow rate provision for remote display andor control

Gravimetric Feeders

Get Price Quote

Demech has entered into technical collaboration with Hitachi Power Europe GmbH (HPE), Duisburg, Germany; to manufacture Gravimetric Coal Feeders. This gives Demech the unique advantage to supply Gravimetric Coal Feeders using the proven and reliable designs of Hitachi Power Europe GmbH. HPE – a subsidiary of Hitachi, Ltd., designs and constructs fossil fired boilers for power generation. They have been the world class quality manufacturers of all the key components of such as utility steam generators, Environmental engineering, Turbines, Pulverisers, Ash Handling systems. The major function of Gravimetric Coal Feeders is to continuously feed specified required quantity of raw coal from the overhead bunkers to the coal pulveriser.

Rotary Feeders

Get Price Quote

As a renowned Vibratory Feeder Manufacturer, the company offers excellent performing Rotary Feeders. These Rotary Feeders do not require any type of controller or a vibrating electro-magnetic coil. Our Centrifugal Rotary Feeders are fitted with a Gear Box & Motor with a Rotating Disc, which rotates the components and places them in the provided oriented chute. Centrifugal/Rotary Motorized Feeders are speedier in output then the Vibratory Bowl Feeders. Attributes • Excellent performance• Fitted with gearbox and motor• Rotates components evenly• High speed• Improved efficiency Application Areas • Food Industry• Textile Industry• Paper Industry• Rubber Industry etc.

Table Feeders

99,000 - 100,000 Per Piece

We are the leading supplier of this products.

Apron Feeder

Get Price Quote

Apron Feeders are provided for extraction of material from hoppers and bins and for applications having high impact loads. In addition, these are also used to control the feed rate of more abrasive, heavy and lumpy materials. Apron feeders are used in mines & minerals, steel plants, coal fields, cement plants, thermal power stations, quarries and ports & harbors. In addition, they are also extensively used in aggregate making, crushing screening, heavy chemicals and paper mills. Teknik has supplied an Apron Feeder with a capacity of 2000TPH and 20 Meters Length for controlling the feed rate of Iron ore in a ship loading system. Teknik has also supplied Apron Feeder to Star Cement, Meghalaya for 1200 TPH for limestone handling.

Electromagnetic Feeder

7,400 - 7,500 Per Piece

bowl feeder

Get Price Quote

Universal Flexible & Reliable sortimat bowl feeders store, convey, sort and orient multiple parts of many shapes and sizeson an incline that spirals around the outside of the bowl. Bolted, interchangeable baffles make this an extremely flexible solution. The cylindrical bowl feeder is available in models SM 100�800, the spiral bowl feeder in models SMB 150-800, and the conical bowl feeder in models SMKF 150-800. Sortimat SMIK Bowl Feeder with Integrated Vision System The rapid SMIK bowl feeder with linear-array camera is the ideal solution when it is not possible to sort parts mechanically, or if a single unit is used to feed a number of diverse components. Incorrectly oriented parts are returned to the sorting process, and unsuitable parts leave the feeder, and good parts are correctly oriented. The system is self-teaching, and can also be set to capture data for quality assurance purposes.

Box Feeder

Get Price Quote

Box Feeder is used to feed clay / raw-mix continuously. It consists of a trough fitted with moving metallic slat conveyor at its bottom. A rotating shaft with pedals / digging arms fitted at its discharge end provides uniform discharge while breaking clay lumps.2 Models of ‘Sambharak’ Box Feeder are available – SBF35 and SBF15.

Table Power Feeder

21 Per Set

1 Set (MOQ)

Easy Clean Rotary Feeder

Get Price Quote

The easy-clean series rotary feeders can be fast and simply disassembled, thoroughly quick cleaned, sanitized and inspected or maintenance in a minimum amount of time without the use of tools or removal from service, thereby reducing downtime and increasing system production. Reassembly without tools is accomplished in minutes. Internal clearances are automatically re-established every time. The Clean-in-place rotary feeder is a special purpose valve designed for where cross-contamination is a major concern and lengthy shut-downs for clean-out are cost-prohibitive, suited for Dairy, Pharmaceutical industries, Food, Baking, Chemical, Plastics, Paint, and Powder Coating plants. It is ideal for batch mixing systems such as those handling different colored resins which demand regular cleaning between cycles.