Slide Gate

Slide Gates are used to control and isolate the discharge of bulk materials from hoppers, bins, silos or conveyors. Slide Gates consist of a rigid frame mounted to the bottom of the storage device or conveyor. A slide plate is located inside the frame that either opens or closes against the flow of material. The slide plate can be moved by manual, pneumatic, electric or hydraulic means. The slide plate being a wear component is made from high wear resistant material & can be offered in various MoC�s. IFI manufacture slide gates to meet specific customer requirements & sizes.

...more

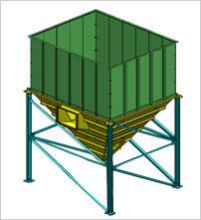

Single Hopper Entry

Bag Filters up to 20,000 m3hr with high efficiency filtration systems are commonly used in the Industry. Single Hopper entry is the most common type of Dust Entry method.

...more

SCREW SAMPLERS

The screw sampler is designed for sample extraction of dry and non-sticky powdered material from a duct or chute through which free flow of material is taking place. The sampler is driven by a geared motor coupled to a transport screw, crossing the flow of material. As an option, the screw sampler can be equipped with variable speed geared motor. The screw transports the extracted material to a discharge outlet chute where the material falls by gravity to the subsequent sample preparation equipment. The screw sampler type size and design is based on chute dimension in mm as well as chute form. It can be mounted in chutes (rectangular or circular) The control of the sampler is normally conducted from your central PLC system or local control is also possible. It can be equipped with a motion detector as an option. Manual type Screw Samplers are also available upon request.

...more

Screw Conveyors

A screw conveyor can be installed at any operating angle. IFI Screw conveyors are designed to operate under harsh conditions and can handle a variety of dry bulk materials such as cement, lime, raw meal, apatite, urea, fly ash, gypsum etc. The screw conveyor is totally enclosed, with no spillage, hardly any dust creation and a very low level of noise.

...more

SACK SWEEPER

Cleans the sack from bottom, sides and top Installed at the sack discharge end of Rotary Packer. Recovers the spillage and dust on the sack Keeps the packing area clean Improves the working environment Uses the draught of the packer No extra air used Single drive in the form of geared motor The bed of the sack sweeper is made of powered rollers. The hollow rollers are fitted with brush that rotates in the opposite direction to make the brushing effective. The top brushes are also powered and fitted with bristles that can clean the sacks from top and sides. The level of the top brush can be adjusted to compensate the reduced length of the brush when it wears off. Safety covers are fitted on both sides. These covers are loaded with gas springs for ease of opening and closing. The drive is in the form of cascaded chains and sprockets – powered by a geared motor. The drive can be located on either side of the sack sweeper. The rpm of the geared motor can be chosen to suit the packer throughput. Top bonnet can be opened and closed with ease with the help of gas springs. Emergency stop push buttons are provided in all the four corners of the sweeper module

...more

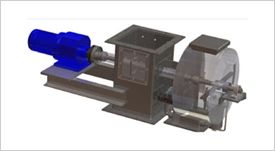

Rotary Air Lock Valves

Rotary Air Lock valves are one of the most commonly used Dust Extraction Systems in the Process Industry. A rotary valve or airlock is used to feed solids between areas of differing pressure while still maintaining the pressure differential and product flow. The word ‘rotary’ refers to the fact that during operation of a rotary airlock, the vanes turn or rotate. As they turn, the pockets, which are formed between the vanes, become rotating pockets. The bulk material being handled enters the pockets at the top, through the Inlet port, travels around in a rotating motion, and exits at the bottom, or through the Outlet port. As the vanes and pockets continue to turn, material continues to be moved from top to bottom, or from Inlet port to Outlet port, in a rotating motion.c

...more

Rigid Emitting Electrodes In Rigid Frames

The ionisation process is governed by corona generation in an esp. The specially designed pipe & spike emitting electrodes can generate desired amount of corona for a particular application. The nails welded to the pipe provide sharp points for higher corona emission. The number of nails per meter of electrode decides the corona density. With our experience in various applications we can engineer correct characteristics of corona densities. The corona density requirement changes from first to last field and a suited design for individual filed is engineered. A continuous fabrication line produces high quality electrodes as per the desired user specifications.

...more

REMOTE MONITORING ANALYSERS

Ionisation Filtration Industries Pune is a leading manufacturer, of various pollution measuring sensors and devices. It has approximately 400 number of installations across India in various type of industries like cement power textile mills etc. As per Central Pollution Control Board (CPCB) State Pollution Control Board (SPCB) guidelines IFI is required to set up a dedicated ServerCloud Services in CPCB premises and later in each of the SPCB premises where the data from various installations will be made available. IFI has PlantConnect Monitoring Software for all their requirements like collecting real time data of all industries and display at the server, public portal so general public & concerned authorities can view the data, reports, alarms etc.

...more

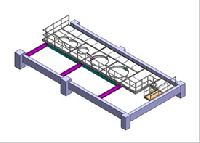

pre fabricated platforms

IFI designs, manufactures & supplies customized platforms which are pre fabricated& to be erected at site. Customized designs allows us to make platform exactly as per user requirements so as to fit in existing space, around existing equipment’s and at varying heights. IFI has internal engineering facilities to design platforms which are load bearing platforms on case to case basis. Pre-fabricated platforms, staircases, ladders, railings allow easy erection at site which can be completed in the least possible time. Platforms can be made in various MOC’s like Mild Steel which can be Painted or Galvanized. Stainless Steel platforms can also be manufactured on request.

...more

POWDER DOSING SYSTEM

IFI has been a pioneer in applying Air Pollution Control Techniques in day to day process operations. A striking example of this pioneering approach is IFI’s Simple & Efficient “Sack Feeding & Dosing system”. Compact, Sturdy & Ergonomically designed to suit various industrial applications. This unique equipment can be effectively used for dosing of various powders in the food, cosmetic, chemical and dairy industry. At the heart of IFI’s Dosing system is a custom designed Dust Filter with Cleaning Arrangement, a Fan optimally designed and a Screw Conveyor which feeds the desired quantity of material into the onward system.

...more

OFFLINE CLEANING TYPE BAG FILTER

An Offline Cleaning Pulse Jet Bag Filterconsists of a number of Chambers. Each Chamber acts as an Online PulseJet Bag Filter. The uniqueness of the design is in thefact that the supply of inlet gas to the Chamber is stopped during cleaning temporarily. Dust falls into the hopper after the bagsare purged with compressed air, since there are no incoming gases into theChamber the dust collection is faster. Dust is evacuated using a Rotary AirlockValve. Remaining chamber’s continue toremain in operation and continue the filtration process.One after the other each chamber is made offline for Bag Filter cleaning & the process continues in cycles. Each Chamber is made online or offline by operating pneumatically operated Poppet Dampers at the inlet & outlet of the Chamber.

...more

multi louver dampers

Multi louver Dampers manufactured by IFI offer a perfect solution to regulate and control gases in various process industries. They are a type of venetian blind made up of various parallel blades which can be opened and closed in parallel or in opposite directions. The blades normally have an aerodynamic profile which minimizes head losses. These are designed in circular or rectangular form according to the installed situation. A defined number of damper blades determined by the duct cross section and damper function are arranged in a robust flanged frame. The actuation of the damper can be manual, motorized or pneumatic as the case may be. Actuators can be the onoff type or regulation type to which Proximity Sensor can be added, we can give signal to control room based on the level of automation required.

...more

MISSION MONITOR

Emission Monitor model EM919 is an indigenous product for measuring dust concentration. This device operates on the principle of optical transmissometry, using single pass of a divergent light beam. It can be installed directly on the outlet stack. The dust concentration is measured depending upon the amount of light blocked by suspended articles in exhaust gas. Advanced techniques are effectively used to detect & compensate for errors due to ambient light as well as stationary dust giving accurate emission readings. Unique design of Swirling Chamber ensures effective cleaning of lenses. Due to its unique algorithm of time-based accumulation of opacity, the EM919 can give emission per normalized gas volume (i.e. in mgNm3)

...more

Fabric Filter Leak Detection System

Fabric Filter Leak Detection System. Ionisation Filtration Industries Pvt. Ltd. has always believed in offering new Technologies to our esteemed customers at affordable prices & at the same time maintaining world-class quality. Finding leakages in a fabric filter is a laborious process which takes time & is often not carried out satisfactorily. Leak Glo Manufacturer With the Fabric Filter Leak Detection System – maintenance of Fabric Filters has taken a quantum leap. Its ease of use & reduction in downtime of Fabric Filters makes it the preferred choice of all Maintenance Engineers. The powder when thrown into the Bag House will follow the Path of the Gas. Where there is a leakage the gas will tend to exit through it. The fluorescent powder when it passes along with the gas through the leakage will glow in UV light supplied along with the Powder – identifying the leakage with ease.

...more

bag filter cages

onisation Filtration Industries Pvt. Ltd. has taken a step forward and improved its manufacturing capabilities by setting up its own automated brand new line of Cage Manufacturing. IFI has always been a pioneer in offering new Technologies to our esteemed customers at affordable prices & at the same time maintaining world-class quality. With the newmanufacturing unit is based in Pirangut, located on the outskirts of Pune, Maharashtra, we are geared up to manufacture more than 1000 Cages per day. Bag Filter Cages Our cages are available in a variety of configurations, finishes and materials, including stainless steel.Heavy duty shipping crates are used to protect the cages during shipment and at the site.

...more

Guillotine Dampers

Guillotines provide a mechanized means of inserting a duct blanking plate and offer superior isolation of flue gas applications containing heavy particulate loads and are ideal for tight shut off applications. IFI guillotine damper, has the main function of isolation of equipment to permit inspection, maintenance, or repair in addition to process isolation. Occasionally, guillotine dampers are specified for bypass ducts, if operation requirements allow enough time for the slow-moving blade to travel across the opening. The standard guillotine model is designed forassembly to be performed in such a way that the gate slides vertically. The guillotine damper is made up of a gate whichslides along metal guides, closing the conduitcompletely. The ends are joined to the conduits bymeans of flanges. The guillotine damper isnormally supplied as a single part. The body of the guillotine damper can beinsulated externally depending upon application requirement

Feature : Maximum leakage protection can be obtained depending upon sealing design. Good isolation. Low pressure drop across the wide open damper. Etc.

...more

Gas Distribution Screen

Turbulent Gas flow & Higher Inlet velocity of the Dust Laden Gas can hamper the performance of the ESP. Upgrade your ESP with IFI’s uniquely de-signed Gas Distribution Screens to help you get the best out of your ESP.

...more

Electrostatic Precipitator

There was a time when smoke bellowing out of a chimney was considered to be a sign of industrialization. In today’s environmentally cautious age—even the analysis of suspended particles in “visibly clean” gas is mandatory. ESP has proved itself time & again to be the most economical equipment for handling high volume gas. Thus making it the first choice for various industries. With Ever increasing number of industrial processes, the importance of the ESP has increased considerably. The latest advancements in Electronic Control Systems has proved itself in enhancing the reliability & performance of the ESP’s. IFI brings the latest in ESP Technology right to your door step to fulfill the ever increasing needs of the industry.

...more

double flap valve

Double flap valve is continuous material discharge equipment. Double Flap Valve has a two door flap plate which open and close alternatively. As the material falls on the top plate, during continuous operation the plate opens and discharges the material on the bottom plate. After discharging the material the top plate closes. This ensures that the DFV is sealed to prevent air leakage. The bottom plate then opens after the top plate is closed and allows material to fall onto onward collecting equipment. The cycle time is precisely adjusted such that after the bottom plate closes the top plate opens. Thus ensuring continuous air sealing across the DFV. The time for which both flap are in closed condition, is known as dwell time.

...more

Diverter Gates

Diverter Gates manufactured by IFI offer a perfect solution to the diversion of Solid Materials from a single point to two different delivery pointsregulate the amount of flow to various circuits, and to isolate circuit for maintenance. They are ideal for diverting gravity flow of materials. They can be as basic as a single to double diverter with a manual lever to Change blade position from one side to the other, or they can be fully automated devices capable of controlling flow from one or more sources to various points. The diverter gate can be actuated while material is being conveyed. This allows faster, more efficient changeovers without the need to shut down the system before activating the diverter. Cylinder mounted limit switches can be fitted as optional extras. Flaps for diversion are provided with Spring Steel Tips which offer very high sealing efficiency & durability.

...more

Common Causes Fabric Filter

Pin Holes Developed in the bag due to hot dust carried along with the gases.Cracks developed in the bag due to hardening of the fabric on account of moisture in the bags.Burr on the Cages – which cause tearing of the fabric under compressed air purging.Compressed air purging eroding top portion of the bag due to damaged or no ventury fitted. Abrasion at bottom of bag due to direct gas flow hitting the bags on account of improper Gas distribution in the bag filters. Leakages around Tube Sheet due to improper Bag Fitment or Welding Gaps. Representative Image of Fluorescent Powder being sprayed into hopper access door If the problems are not attempted promptly & in time it may lead.

...more

Collecting Electrode Upgrade Package

The specific collection area of an ESP decides its collection efficiency. Bent, warped, corroded plates hamper the performance. Getting correct profile of the colleting plates is often difficult task. This problem is put to rest by IFI by devising a concept of adaptive weld-mets, which ensures the new collecting plate fits exactly like the original design. The conversion from side to top rapping can fetch up to 33% increase in collection area. Other Upgrades IFI offers Design & Installation of Turning vanes also known as Gas Distribution vanes into the Inlet Duct of the ESP. This helps in Directing the Gas correctly into the ESP. Reducing Frictional Losses Increasing the Efficiency of your ESP.

...more

cartridge bag filter

IFI offers high filtration efficiency Cartridge type bag filters for critical application which require high filtration area at the same time very less area is available for fitment of the bag filter. These compact bag filters use compact filter cartridges with inbuilt cages. They are available in a wide array of shapes and sizes. Talk to us for any specific requirement that you may have.

...more

Butterfly Dampers

IFI Butterfly dampers are available for a wide variety of applications in round ductwork, where low-leakage isolation, flow control, or a combination of the two is desired. Varying degrees of isolation can be obtained from 90 to 99.9% depending on the seal arrangement. Heavy-duty design that is suitable for applications with clean, corrosive, dirty, andor dry environments. Manufactured in-house under strict quality control procedures. IFI�s range of butterfly dampers are best suited in Duct and Ventilation system where flow control and balancing is required.

Feature : No leakage,Excellent for isolation & balancing of ducts,Lower cost Etc.

...moreBe first to Rate

Rate This