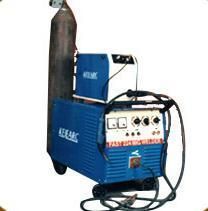

welding controller

400,000 Per Piece

Material : Mild Steel

Frequency : 50Hz

Voltage : 440V

...more

Vertical Metal Gathering Machine

Application : Engine Valves , Hand tools, Fasteners, Pushrods, Bolts, timer pins, torsion spring rods, spline shafts etc.

Type : Vertical, Hydraulically operaed

Universal Seam Welding Machine

600,000 - 1,200,000 Per

Type : Pneumatic, Press Type

Traction Motor Tig Welding System

TIG Welding Machine

TIG welders are compact, robustly built for high quality TIG welding of stainless steel, alloy steel, heat resistance alloys, copper, nickel and their alloys from 0.5 to 3.0mm thickness

...more

Automatic TIG Welding System For Textile Machine

Voltage : 110V, 220V, Etc

Power : 1-5kw, 10-15kw, Etc

Driven Type : Electric

Weight : 100-1000kg, Etc

...more

Stator MIG Welding System For Submersible Pump

Spot Welding Machines

150,000 Per Piece

Frequency : 50 Hz

Voltage : 415V

Phase : 2 phase

...more

spot cum projection welder

200,000 Per Piece

Voltage : 300 V

Spm Welding Machine

400,000 Per Piece

Usage/Application : Industrial

Voltage : 280 V

Rotary Welding Machine

Two station Mig welding system is developed for stator of the submersible pump. The machine incorporates hydraulically operated mechanism for clamping the stator horizontally and weld the S. S. tube with M. S. end rings. This Mig welding system replaces manual Tig welding through welding automation giving excellent weld bead. This process reduces the production time dramatically to three minutes instead of thirty minutes.Since welding is carried out automatically, the dependence on a skilled operator is eliminated. Thus this is an important in the hand of submersible pump maker to improve weld quality, improve productivity and eliminate skilled man power. Applications: Many applications like welding S.S. Stator to end rings in Submersible pumps, Idler rollers for conveyors, Tig welding system for traction motor, Mig system for flex plates, silencers in automobiles, many many jobs can be easily produced using rotary welding systems.Features: These Spm's have state of art technology. They provide high production rates at less or no operator skill. Choice: Usually have one or two power sources with respective welding heads. You may choose between Tig & Mig depending on the material you may want to weld & other parameters like strength & porosity. Operation: The jobs are clamped at appropriate pressure & rotated by a geared motor. The weld torches approach the job pneumatically & weld the job circumferentially. The weld bead uniform as are voltage is used as a feed back. Salient features High Welding speeds Uniform weld bead. No operator skill Tailor made to suit customer needs. Excellent performance. Sturdy & rugged. Choice of PLC & full automation with material handling.

Type : High Welding speeds(SPM)

Specialities : No operator skill

Usage : Tailor made to suit customer needs

Specialities : Choice of PLC & full automation with material handling

...more

Continuous Rod Heating Machine

Application : Lamination, Pesting, Pressing

Voltage : 110v

Automatic Grade : Automatic

Type : Continuous Rod Heating Machine

...more

Stationary Brazing Machine

250,000 - 1,050,000 Per Piece

1 Piece (MOQ)

applications: metals and alloys except those whose melting point is below 400 deg. c as lead, tin fuse links tungsten silver tip on copper contacts tungsten carbide tips copper to copper parts of various sizes and shapes copper to brass terminals to transformer leads brazing of clips and connectors to cable

Power : Low Power Consumption

Brand Name : Kejearc

...more

Projection Welding Machine

Application: Weld-nuts To Sheets. Fastener-bolts To Sheets Handles To Various Sheet Assemblies Including Drums & Containers. Cross Wire Welding, For Wire Mesh. Pins, Brackets To Different Assemblies. Welding Of Various Automobile Components.

Type : Pneumatic, Press type

Feature : Sturdy ‘C’ steel frame assembly

...more

Pedal Spot Welding Machine

48,000 - 97,000 Per Piece

Application: The machines have been designed to suit various requirements covering several industries. The Automobile industry, Wire industry, Air conditioners, Refrigerators, Textiles machines, Water heaters, Electric appliances, Transformers, Steel furniture, containers, Barrels & drums, Fuel tanks, Motors, Switchgears, T.V., etc. are amongst a wide range of applications.

Weight : 100-500kg

Finishing : Powder Coated

Usage : Industrial

Type : Pedal Operated

Brand Name : Kejearc

Material : Copper

Color : Blue

Voltage : 415V

Condition : New

Phase : Double Phase

Warranty : 1 Year

Country of Origin : India

Corrosion Resistance : Yes

Machine Structure : Vertical

...more

multispot welding machine

Weight : 100-1000kg, 100-200.200-300, etc

Usage : Bowl Multispot Welding Machine

Operating Type : Automatic

Rated Power : 1-3kw, 110V, etc

Specialities : Long functional life

...more

Mini Spot Welder

MIG welding machine

Type : High arc stability with auto choke

Application : Concentrated heat application

Features : Near endless welding without change of electrodes

...more

mag welding machine

Type : High arc stability with auto choke

Longitudinal Seam Welding Machine

500,000 - 800,000 Per Piece

Type : Press Type

Linear Welding Machine

Automatic tig welding system for textile machinery Customer : Textile machines manufacturer Details : An SPM was developed for a textile machine manufacturer. Coimbatore. Tig welding system incorporated state of the art technology complete with Tig welding power source, Twin Welding head carrying to tig torches operated through thyristor controlled servo drives, ball screws, electronic arc feedback controlled, dc motor operated trolly carrying both welding heads. Pneumatic clamping to hold (Stainless steel heat transfer tube) the Job. The entire welding of 3 mtrs is carried out in less than 3 minutes with high accuracy. The welding is fusion welding with TIG Process. These systems comprises of state of art technology. They come with a choice of Tig or Mig welding & single or twin torches. The welding head welds the job in one axis in a straight line (longitudinally). The welding heads are operated through thyristor controlled servo drives, ball screws, electronic feed back controlled. Salient Features includes: High Welding speeds Uniform weld bead. Elimination of operator skill. Customized Rugged Choice of full automation

Type : High welding speeds (SPM)

Specialities : Uniform weld bad

Specialities : Choice of full automation

...more

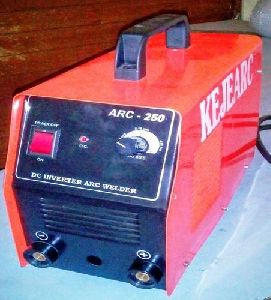

Inverter ARC Welding Machine

1 Piece(s) (MOQ)

Weight : 20-30kg, 30-40kg, 40-50kg, etc

Power : 1-3kw, 3-6kw, etc

Automatic Grade : Manual

Brand Name : KEJEARC

...more

Idler Roller Mig Welding System

Thickness : 0-10mm, 10-20mm, etc

Finishing : Polished

Feature : Excellent Quality

Loading Capacity : 10-15kg, 15-20kg, etc

...more

Hot Plate Welding Machine

Voltage : 110V, 220V, 450V, etc

Power : 1-5kw, 10-15kw, etc

Driven Type : Electric

Weight : 100-1000kg, etc

...more

Repairing Services

Opening Hours

Keje Electric Company is a name that is counted amongst the preeminent manufacturers, exporters, and suppliers of metal gathering machine, linear welding system, Arc welding transformer, pneumatic spot welding machine, and many more. Owing to our R&D team, we stay ahead of our competitors and continuously improvise the quality, functionality, and cost effectiveness of our products. All our personnel are well-versed with latest technology and client demands. Our manufacturing unit is equipped with high precision machine, finest wielding facility, jigs, fixtures, in-house H class transformers, and efficient tooling. Besides this, we have a quality testing set up that helps us meet international standards. The products are manufactured by our biggest asset, which is our manpower consisting of efficient engineers, skilful men, and technicians. We are able to market our products internationally with some of major exports to Sri Lanka, USSR, Africa, and other various countries.

Headquartered in Pune (Maharashtra, India), Keje Electric Company is one of the well-known companies that are engaged in manufacturing, exporting, and supplying the best quality industrial machines and equipment. It was incorporated in the year 1975.

Our Team

Backed by a team of technocrats, we are able to deliver a flawless range of products to our clients. Our quality controllers keep a stringent check during the production procedure till the packaging. Besides this, our marketing team works hard to promote the products in the markets. Our R&D enables us to keep up-to-date with latest market trends.

Quality Assurance

We follow a streamlined quality assuring strategy for the fittings, equipment, and machinery. Our product line is at par with the international standards. Some important tests conducted are durability, performance, sturdiness, and energy consumption.

Manufacturing Unit

Spread in an area of 10000 square feet measuring 6000 square feet, our infrastructure is located in the prime industrial area. Our manufacturing unit is installed with lathe machines, grinders, shapers, planners, welding machines, and cutting machines.