Windscreen Wiper Systems

Whether pneumatically or electrically powered, Knorr-Bremse windscreen wiper and wash systems cover the whole spectrum of rail vehicles: whether tramway, metro, locomotive or high-speed trains. Windscreen Wiper The product portfolio ranges from systems for segmental or parallel wipe areas to applications with overlapping wiped areas with electronically synchronized wiper drive units. Of course, all of them are exclusively equipped with components tried and tested by Knorr-Bremse. The systems are characterized by their extremely long lifespan and reliability, resulting in optimized life-cycle costs. This is especially beneficial for the operator. Other advantages are the pre-assembled drive units which considerably reduce the vehicle manufacturer’s installation costs.

...more

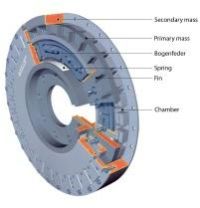

Viscosity Rotary Oscillation Dampers

Visco-Dampers reduce rotary oscillation by the elastic andor damping combination of secondary mass (gyrating ring) and primary mass (housing)

...more

Pedal unit

Pedal units with integrated clutch actuation systems are also included in Knorr-Bremse�s wide range of valves. These modules, constructed on the �Plug-and-Play� principle, offer the customer significant technical as well as logistical advantages.

...more

Train Entrance Systems

It is easy for delays to occur while passengers are getting on and off the train. The quality of the access system, therefore, has an important influence over the operating efficiency of rail vehicles. Calculations show that the advantage to a business of a high quality access system exceeds its procurement costs by up to ten times. The security and the comfort of the passengers are always in focus when developing a detection systems and access devices.

...more

Knorr Bremse Servo Shift module

The Knorr-Bremse Servo-Shift module is a pneumatically operated, servo-assisted shift system for manual transmissions. Thanks to the reduced shifting forces, the system allows a quick and comfortable gear change for maximum road safety and supports the driver in selecting the correct gear for the optimum fuel consumption. A combined servo force and shift speed limitation also protects the synchronization units of the gearbox. The Servo-Shift module can be adapted quickly and easily to suit various gearbox types. The application of the module can be realised via gear linkage or bowden cable system.

...more

sanding systems

Sanding systems are used in rail vehicles to improve friction between wheel and track. Operation is either automatic or can be initiated by the driver, who can use it in a targeted way for starting-up and braking. Sanding system During emergency braking, sanding is automatically activated. The sand is contained in a sandbox and, when necessary, is conveyed by compressed air between the wheels and the track. Advantages: Optional 2 stage or continuous speed dependent sanding Complete pre-assembled sandboxes: Plug & Play Compact design Economical life-cycle costs Knorr-Bremse, as a competent partner, offers all the components for a sanding system:

...more

Sanding system

Sanding systems are used in rail vehicles to improve friction between wheel and track. Operation is either automatic or can be initiated by the driver, who can use it in a targeted way for starting-up and braking. Sanding system During emergency braking, sanding is automatically activated. The sand is contained in a sandbox and, when necessary, is conveyed by compressed air between the wheels and the track Advantages: Optional 2 stage or continuous speed dependent sanding Complete pre-assembled sandboxes: Plug & Play Compact design Economical life-cycle costs Knorr-Bremse, as a competent partner, offers all the components for a sanding system: Air Supply This comes from the vehicle air supply or from a dedicated, small electric compressor.

...more

Platform Door Systems

Platform screen door systems make a significant contribution to platform safety, air conditioning and the cleanliness of the boarding area. They extend the entire length of the platform. The cars come to a halt in such a way that the vehicle doors and the platform doors are adjacent. Every platform door is made up of and automatic sliding door with two wings. This door is integrated into a glass wall element. The door control is protected from unauthorized access by a sealed housing. Platform sills give the doors and wall elements additional stability.

...more

On-board Auxiliary Power Converters

Knorr-Bremse PowerTech is a specialist in advanced auxiliary power supply for all types of rail vehicle – LRVs, high-speed trains, metros, locomotives or long-distance passenger cars. On the basis of our extensive portfolio we develop the right solution for your specific requirements – and of course world-wide service is included. Product features for regional and long-distance Suitable for UIC-standard input voltages Several individual AC and DC outlets AC output range 15 kVA to 120 kVA DC output range 5 kW to 25 kW Available for installation under floor, on roof or in cabinet Compact and light-weight design thanks to medium-frequency technology Forced-air cooling

...more

LCV R&P Steering System with iHSA Control Module

In the LCV steering systems segment, tedrive stands out due to some unique technical features: the robust, modular steel housing technology and the optional use of the iHSA control module – and therefore the integration of all safety and comfort features also for light commercial vehicles; a first in this class of vehicle. In comparison to conventional aluminium steering housings, steel housings offer greater rigidity, toughness and improved quality through the elimination of porosity. These properties have a noticeable effect on optimizing the steering precision of the transporters. A reliable addition to commercial vehicle steering systems is the integration of the intelligent steering assist iHSA®.

...more

Knorr-Bremse Drum Brake

Knorr-Bremse develops, manufactures and markets S-Cam drum brakes and slack adjusters. Together with pneumatic brake actuators and brake drums they represent a foundation brake system. Knorr-Bremse Drum Brake Function of the product With all types of drum brakes, friction forces are generated by internal brake shoes being pressed against the inner surfaces of the brake drum by the force generated by a cam. Due to their almost completely sealed housing, the brake shoes are well protected against corrosive influences (water, salt, dust) and dirt (sand, stones and mud), even when driving on rough

...more

brake pad back plate

ProTecS® The connection between the brake pad back plate and spring holder ensures precise utilisation of the spring’s elasticity and thereby optimal alignment of the brake pads. The construction of the spring system increases the life expectancy of the brake pads, especially on rough roads. In addition, the welded spring holder acts as a slider resulting in protection of the spring and pad retainer, thereby reducing wear and tear. Due to the reduced friction between the spring holder and pad retainer, the ProTecS® pads return from their contact with the disc more easily. An additional improvement, combined with the introduction of the ProTecS® system, is the cast back plate. The lighter weight of the plate reduces the inertia of the brake pad, resulting in a reduction in noise development. An additional benefit is a reduction in the deformation of the brake pad in contact

...more

iHSA Control Module

tedrive has developed the intelligent hydraulic steering system iHSA (= intelligent Hydraulic Steering Assist) – an innovation sustainably influencing the market for vehicle steering systems. By means of its torque overlay, iHSA offers safety, comfort and an interface with modern driver assistance systems and thereby allows the integration of lane departure warning systems, side wind compensation, etc. The hydraulic technology is variable, front axle load-independent and environmentally-friendly. In addition to the improved steering functions, the advantages of the iHSA hydraulic steering system of tedrive include its optimized installation dimensions, cost and design advantages for platform strategies and the CO₂-saving potential of the pump and steering gear. Through the integration of the iHSA control module into the base rack & pinion or recirculating ball steering gears, the technology is available for cars, light commercial vehicles, trucks and buses.

...more

Hydraulics

Passengers today expect a lot from modern local public transport vehicles. They demand a high degree of freedom of movement, comfort and safety. As a result, the amount of space available for installing braking systems is becoming increasingly limited. Hydraulic brake caliper The challenge today is, therefore, to design extremely compact, light hydraulic systems, which combine safety, flexibility and fast response characteristic with high performance. As a solution to this, Knorr-Bremse offers a wide product range which has contributed decisively to the development of new vehicle generations such as, for example, the low floor tramway. Electro-Hydraulic Unit

...more

Hydraulic Dampers

Hydraulic Damper

The HYDROLASTIC damper reduces rotary oscillation in accordance with the hydrodynamic extrusion principle. Rotary oscillation causes a relative motion in the damper between the primary mass (hub) and secondary mass (housing). As a consequence of this relative motion, mineral oil is pressed through a narrow slot. The resulting drop in pressure equates to a hydraulic drop in power, which has a damping effect.

...more

HSA Control Module

tedrive has developed the intelligent hydraulic steering system iHSA (= intelligent Hydraulic Steering Assist) � an innovation sustainably influencing the market for vehicle steering systems. By means of its torque overlay, iHSA offers safety, comfort and an interface with modern driver assistance systems and thereby allows the integration of lane departure warning systems, side wind compensation, etc. The hydraulic technology is variable, front axle load-independent and environmentally-friendly. In addition to the improved steering functions, the advantages of the iHSA hydraulic steering system of tedrive include its optimized installation dimensions, cost and design advantages for platform strategies and the CO�-saving potential of the pump and steering gear. Through the integration of the iHSA control module into the base rack & pinion or recirculating ball steering gears, the technology is available for cars, light commercial vehicles, trucks and buses.

...more

air conditioning systems

Conventional or heat pump systems Compact package or split systems Roof, inside the car or under car installations Passenger and drivers cab area Microprocessor based temperature control Air quality systems Fire and smoke detection systems Airduct systems (new and retrofitted vehicles)

...more

Hand Brake Valve

EP Compact

Brake control is an extremely safety-relevant sub-system of the train due to the fact that it must allow reliable stopping of the train in all operating conditions. EP Compact Optimum braking is achieved if operation of a single lever by the driver results in an individual braking force being applied to each axle or bogie of the train. As the driver himself is not in a position to apply the brakes with a specific force to each axle or bogie, modern brake control systems need to have a large number of integrated intelligent functions:

...more

Engine Air Exhaust Brake

Exhaust Brake Exhaust Brakes are used on diesel engines to provide vehicle retardation by choking the exhaust gas flow downstream of the turbocharger. The exhaust brake has a throttle valve which is actuated by a pneumatic operating cylinder. The back pressure realized by a conventional uncontrolled exhaust brake is proportional to the engine speed. The controlled exhaust brake however is equipped with a mechanism that maintains a constant counter-pressure downstream of the turbocharger in a defined gas flow range. This consequently allows constant retardation that is independent of engine load and speed.

...more

Engine Air

Exhaust Brake Exhaust Brakes are used on diesel engines to provide vehicle retardation by choking the exhaust gas flow downstream of the turbocharger. The exhaust brake has a throttle valve which is actuated by a pneumatic operating cylinder. The back pressure realized by a conventional uncontrolled exhaust brake is proportional to the engine speed. The controlled exhaust brake however is equipped with a mechanism that maintains a constant counter-pressure downstream of the turbocharger in a defined gas flow range. This consequently allows constant retardation that is independent of engine load and speed

...more

electronic systems

t is estimated that, in the European Community, the equipping of all trucks and busescoaches with electronic systems would result in 500 fewer deaths and 2,500 fewer injuries due to road accidents per year. Knorr-Bremse is pressing ahead with the development of active and passive driver assistance systems and is thereby making a significant contribution to increasing safety on the roads. The product program in the area of electronic systems ranges from legally required ABS (anti-lock braking systems), through EBS (electronic braking systems) to ESP (electronic stability program) and ACC (adaptive cruise control). ABS, ASR ABS prevents locking of the wheels when braking, while ASR (traction control system TCS) ensures that, when accelerating, the wheels on the drive axle do not spin, thereby ensuring optimal traction in all driving conditions. As a pioneer in the development of ABS systems for commercial vehicles, Knorr-Bremse provides ABS and ASR systems for all vehicles types and trailers with air braking.

...more

Electronic Gear Control Unit for Automated Manual Transmission (AMT)

An electronic gear control unit allows a fully automatic gear change to be made with a manual gearbox; the unit is usually directly mounted on top of the gearbox. The electronic gear control unit is a combination of mechanical components (e.g. pneumatic cylinders) as well as electrical components (e.g. solenoid valves, cables, electronic control units). Due to the integration of several functions, today�s automated manual transmission (AMT) modules reach an enormous degree of complexity. An AMT is the basis for the improvement of the driving comfort and the reduction of the load of the driver. The driver is able to focus his attention on the road traffic; there is no need to concentrate on the gear selection and gear shift process any more. The use of an optimized gear shift strategy (selected by the system and based on the driving situation), means that AMT can significantly reduce fuel consumption and mechanical wear in e.g. tractortrailer couplings when compared with conventional manual gear box operation.

...more

Electronic Air Treatment services

Be first to Rate

Rate This