Storage Tanks

We offer highly effective industrial storage tanks that are developed using high quality M.S and SS material. Our tanks are widely used in various industries and commercial application for the purpose of storing liquids. Widely appreciated for its features of corrosion resistance, high strength, and robust construction, the product can be customized as per the client specification and requirement.

...more

Spray Dryer

Spray Dryer method OR process is the most economic method OR process of evaporation to convert liquid feed OR slurry having specific percentage of solids to solid powder particles. Still powder is one of the most cost effective in both storage & transportation of finished goods. We provide turnkey projects of Spray Dryer for MCCP, Microcrystalline Cellulose Powder, Zinc Sulphate Powder, Sulphur WDG Powder, Herbal Extract. SCOPE Our Spray Dryer Technology has developed a wide range of Spray Dryer Chambers to suit the widest range of material Our Scope of plant ranges from 5 kg/hr laboratory models to full scale high volume production models in excess of 5000kg/hr and can meet any required industrial manufacturing specification HIGH STANDARDS Customers required whatever the size of plant OR specification ,all our plants are designed for higher strengths standard than many spray dryer manufacturer

...more

Spin Flash Dryer

Spin Flash dryer are designed for continuous drying of pastes and filter cakes. The main components of our spin flash dryers are a feed system, the patented drying chambers, and the bag filters. This system consist of feed vat and screw feeding system which is used to deliver or feed the material into the spin Bowl OR drying chamber where the product is buffered and fragmented by an agitator prior to continuous drying. A variable speed is kept of feed screw to control the discharge of feed. The rotor of the drying chamber fluidizes product particles in a drying efficient hot air flow patterns in which any wet lumps are rapidly disintegrated. Hot air comes from temperature controlled air heater, entering the drying chambers at a tangent in order to establish a turbulent, whirling air flow. Powder from the drying chamber is controlled in bag filter or cyclone Seperator while the outlet air leaves the system at the top suction fan, called I.D. fan. Advantage same as flash dryer.

...more

Rotary Dryers

Rotary dryer are used for to reduce or minimize the moisture content present in the feed. This feed material comes in direct contact with hot gas .This rotary dryer is made up of rotating cylinder and number of tubes fitted inside. OR only lifters are provided on Periphury. We manufacturer of Rotary Dryer for Colour Speckles, DDGS etc.

...more

Colour Speckles Rotary Dryer

Rotary dryer are used for to reduce or minimize the moisture content present in the feed. This feed material comes in direct contact with hot gas .This rotary dryer is made up of rotating cylinder and number of tubes fitted inside. OR only lifters are provided on Periphury. We manufacturer of Rotary Dryer for Colour Speckles, DDGS etc. The material which is to be dried enters into the dryer and since the dryer is rotating , the material is lifted up by series of internal fins lining the inner wall of the dryer. After getting high enough, the material falls down back to the bottom of the dryer , passing through the hot gas steam and thus the drying takes place . This dryer can be designed either with co-current OR counter current flow. Advantages : Simplicity in design. Sturdy construction. Adaptability to fluctuating feed rates and moisture contents of product Possibility of very large through puts. Can handle wide range of material . Can handle highest drying temperature.

...more

rotary disk atomizer

Spray drying process is very fast and efficient drying process and which allows a short time for evaporation to takes place and for this it is very essential that the feed can be adequately be atomized into a spray of droplets for successful spray drying. This causes fast drying of the droplets as evaporation occurs from the large surface area is generated by the atomizer . The important factors in the atomization are viscosity, size and surface tension , shape and physical behavior of suspended components which determines how well the feed atomises.

...more

Rotary Disc Atomizer

Spray drying process is very fast and efficient drying process and which allows a short time for evaporation to takes place and for this it is very essential that the feed can be adequately be atomized into a spray of droplets for successful spray drying. This causes fast drying of the droplets as evaporation occurs from the large surface area is generated by the atomizer . The important factors in the atomization are viscosity, size and surface tension , shape and physical behavior of suspended components which determines how well the feed atomises. Advantages : Highly viscous material can be handled. High solids can be handled resulting better economy. Large quantity of material can be handled . Different wheel types can be designed according to the different material characteristics.

...more

rotary air locks valves

The Rotary valves are used to minimize leakages of air inside the System. We offer wide range of rotary valves with different types and Specifications to fulfill our different needs. We manufacture open as well as closed type’s rotors with S.S. and M.S. construction and casing in Aluminum casting and M.S. casting. We manufacture both direct drive as well as chain drive as per convenient of customers.

...more

Ribbon Mixer

We are the prominent manufacturer of a wide range of Ribbon Blender. The offered range is manufactured using the finest grade raw material and latest techniques. Apart from this, these blenders are quality tested on well-defined parameters in order to ensure their flawlessness. Client can avail the offered blender from us at the most reasonable prices.

...more

Ribbon Blender

We are the prominent manufacturer of a wide range of Ribbon Blender. The offered range is manufactured using the finest grade raw material and latest techniques. Apart from this, these blenders are quality tested on well-defined parameters in order to ensure their flawlessness. Client can avail the offered blender from us at the most reasonable prices. Features : • Rust and Heat Resistant • Easy Operation • Less mixing Time

...more

Pneumatic Powder Conveying Systems

We provide Pneumatic Conveying System for conveying Powder, Granuels, etc. Our Pneumatic Conveying System is available in food grade stainless steel version, Mild Steel version and also In F.R.P. Material Version. We supply Pneumatic Conveying System as per customer requirements. We manufacturer of Pneumatic Powder Conveying Systems for MCCP Powder, Zinc Sulphate Powder, Lime Powder, Wheat and Rice Flour, etc Features : • Easy to Operate • Increase the Production • Reduce Manpower • Hygienic • Reduce the wastage This is the process of conveying /transporting bulk material through a pipe line by either negative or positive pressure air system. The air , when moving with specific velocity, will carry material comes in its path. This system are designed by vast experience, rather than just by formula. Hindustan offers specialize designed system which offers considerable economy. BASIC COMPONENTS : Blower/ Fan Rotary feeders Loadings Tees Diverter valves Dust separators (optional) Control systems

...more

Pneumatic Conveyor

The company is deep rooted in Maharashtra(India) and has gained a distinguished position in the market. We follow stringent quality measures to ensuring the product quality so as to attain maximum client satisfaction.

...more

Conical Blender

The Nauta Mixer has a conical container which houses a constant flight screw.This screw revolves on its own axis and also around the cone wall.Material of diverse shape, size and densities are homogenously mixed without any deprivation. Application : • Dry Blending, Dry Blending with Liquid Spray. • Features: • Low Power Consumption • Short Mixing Time • Low space require • Gentle mixing action

...more

Material Handling System

We have a wide range of equipment and system for handling ,conveying ,transporting a host of material for various industries. Pneumatic Conveying We provide Pneumatic Conveying System for conveying Powder, Granuels, etc. Our Pneumatic Conveying System is available in food grade stainless steel version & Mild Steel version. We supply Pneumatic Conveying System as per customer requirements. Features : • Easy to Operate • Increase the Production • Reduce Manpower • Hygienic • Reduce the wastage This is the process of conveying /transporting bulk material through a pipe line by either negative or positive pressure air system. The air , when moving with specific velocity, will carry material comes in its path. This system are designed by vast experience, rather than just by formula. Hindustan offers specialize designed system which offers considerable economy. BASIC COMPONENTS : Blower/ Fan Rotary feeders Loadings Tees Diverter valves Dust separators (optional) Control systems

...more

Manhole For Process Equipments

We are the manufacturer of manholes like Stainless Steel and Carbon Steel which are used in Chemical Industries for Process Equipments. We also manufacture manhole as per the Clients specification and design.

...more

Industrial Spray Dryer

Spray Dryer method OR process is the most economic method OR process of evaporation to convert liquid feed OR slurry having specific percentage of solids to solid powder particles. Still powder is one of the most cost effective in both storage & transportation of finished goods.We provide turnkey projects of Spray Dryer for MCCP, Microcrystalline Cellulose Powder, Zinc Sulphate Powder, Sulphur WDG Powder, Herbal Extract.Our Spray Dryer Technology has developed a wide range of Spray Dryer Chambers to suit the widest range of material Our Scope of plant ranges from 5 kghr laboratory models to full scale high volume production models in excess of 5000kghr and can meet any required industrial manufacturing specification.

...more

Fluid Bed Dryer

Fluid bed drying is a process where hot air is passed through a perforated air distributor at a control velocity and the moisture is removed from the product. The process can be used for cooling also with use of dehumidified air. These can be used in combine with spray dryer. Fluid bed dryer is also used for agglomeration, granulation, coating etc.

...more

Flash Dryer

Flash Drying is the new kind of drying system used for drying the material such as pastes OR cake state. The Word Flash means instantaneous or rapid drying of product ,means required short residance time such as few seconds. In Flash dryer the hot air enters tangentially and comes in contact with feed, resulting drying takes place throughout the flash duct removing moisture. This dry material separated into the high efficiency cyclones or bag filter. Flash dryers are used for drying a wide range of products. Salient Features : Ideal for instaneous removal of surface moisture. Ideal for high volume through- puts. Ideal for heat sensitive materials. Ideal for high drying efficiency and low energy cost. No initial dilution is required and hence direct drying takes place. Ideal for use in combination with others drying system particularly fluid bed or rotary dryer. High thermal efficiency. Consistent product quality with uniform moisture content. Low capital equipment cost.

...more

Drum Blending Machine

We offer wide range of mechanical Stirrer machines for mixing purpose of different types of liquid with different range of densities, Viscosities and with different specifications. We also provide Up and Down Movement machine for Stirrer to make convenience to change the drums/ Barrels within short period of time. The Up and Down movement of Stirrers is control pneumatically with high standard materials.

...more

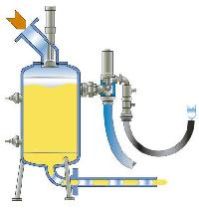

Agitator Storage Tank

We manufacture tanks having capacity in range of 50 liters to 150000 liters, It can be manufactured in different specification as follows. • High and Low speed agitator • Surface finish from 120 grits to 400 grits • Suitable for Indoor and Outdoor installation • Material of Construction SS304/SS316/SS304L/SS316L/M.S. etc.

...more

Nozzles Spray Dryer

Machine Dryer

Air Pollution Control Equipment

Be first to Rate

Rate ThisOpening Hours