Magnetic Particle Testing Services

Get Price Quote

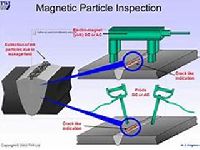

This process used for detecting surface and slightly subsurface discontinuities in ferroelectric materials such as iron, nickel, cobalt, and some of their alloys. The process puts a magnetic field into the part. The reason we use this test is to find small defects in objects before they become bigger defects and cause serious problems. In magnetic particle inspection, a magnet or electrical current is used to establish a magnetic field in the object. Iron filings are then dusted on to the surface of the object. The filings should align along the magnetic lines of force. If a crack or other defect is present, the magnetic lines of force will be disrupted and the magnetic particles will cluster along the edges of the flaw.

magnetic particle testing

Get Price Quote

Magnetic Particle Inspection (MPI) is a Non-Destructive Testing (NDT) process for detecting surface and slightly subsurface discontinuities in ferroelectric materials such as iron, nickel, cobalt, and some of their alloys. The process puts a magnetic field into the part. The piece can be magnetized by direct or indirect magnetization. Direct magnetization occurs when the electric current is passed through the test object and a magnetic field is formed in the material. Indirect magnetization occurs when no electric current is passed through the test object, but a magnetic field is applied from an outside source. The magnetic lines of force are perpendicular to the direction of the electric current which may be either Alternating Current (AC) or some form of Direct Current (DC) (rectified AC). The presence of a surface or subsurface discontinuity in the material allows the magnetic flux to leak, since air cannot support as much magnetic field per unit volume as metals. Ferrous iron particles are then applied to the part. The particles may be dry or in a wet suspension. If an area of flux leakage is present the particles will be attracted to this area. The particles will build up at the area of leakage and form what is known as an indication. The indication can then be evaluated to determine what it is, what may have caused it, and what action should be taken, if any. This examination should apply in a row stage and final stage. Process mostly used for bar stage,forging casting and after heat treatment process .

Looking for Magnetic Particle Testing Service Providers

magnetic particle testing

500 Per Meter

Mt (magnetic particle testing) it is a non-destructive testing (ndt) process for detecting surface and slightly subsurface discontinuities in ferromagnetic materials such as iron, nickel, cobalt, and some of their alloys. The process puts a magnetic field into the part. The piece can be magnetized by direct or indirect magnetization. Direct magnetization direct magnetization occurs when the electric current is passed through the test object and a magnetic field is formed in the material. Indirect magnetization indirect magnetization occurs when no electric current is passed through the test object, but a magnetic field is applied from an outside source. Dry particle inspection in this magnetic particle testing technique, dry particles are dusted onto the surface of the test object as the item is magnetized. Dry particle inspection is well suited for the inspections conducted on rough surfaces. When an electromagnetic yoke is used, the ac or half wave dc current creates a pulsating magnetic field that provides mobility to the powder. The primary applications for dry powders are unground welds and rough as-cast surfaces. Dry particle inspection is also used to detect shallow subsurface cracks. Dry particles with half wave dc is the best approach when inspecting for lack of root penetration in welds of thin materials. Half wave dc with prods and dry particles is commonly used when inspecting large castings for hot tears and cracks. Wet suspension inspection wet suspension magnetic particle inspection, more commonly known as wet magnetic particle inspection, involves applying the particles while they are suspended in a liquid carrier. Wet magnetic particle inspection is most commonly performed using a stationary, wet, horizontal inspection unit but suspensions are also available in spray cans for use with an electromagnetic yoke.

magnetic particle test

Get Price Quote

magnetic particle test, Spark Test, Portable Hardness Test

magnetic particle testing

Get Price Quote

radiography Testing, Liquid Penetrant Testing

magnetic particle testing

Get Price Quote

ndt training services

Magnetic Particle Testing Services

Get Price Quote

visual testing services

magnetic particle testing service

Get Price Quote

x ray service, RLA Testing Service, Infrared Thermography Service