Yag Laser Cutting Machine

YAG laser cutting machine obvious in cost-performance ratio, more suitable for small- batch processing, needs to change consumable parts and need maintenance. 1.7P external cooling water recycling system with filter system. That can decrease water change frequence into 1/6 compare with others. Constant-temperature control ensures circuit water from frozen in Winter.. Applicable Field Widely used for metalsheet processing, advertising trademark, advertising character, high/low voltage electrical cabinet, mechanism parts, kitchenware, cars, mechanical, metal craftwork, saw blade, electronic parts, eyeglasses, spring, circuit board, kettle, medical microelectronics, hard ware, knives tool, measurement, instrument, etc. Applicable Material Stainless steel, carbon steel, alloy steel, spring steel, aluminum, aluminum alloy, galvanized sheet, cincalumzalutite, pickling plate, copper, silver, gold, titanium and other metal sheet, pipes and tubes.

...more

Profile Cutter

Profile cutter Direct rack and pinion of 1.5 Module in both axes for accurate and repeatable motion.Longitudinal and transverse energy feed drag-chains, hose cable clean and move smooth.

...more

Portable Cnc Cutting Machine

Function CNC edit, It can cut different complicated plane figure, Move at hazard, Little shape, High precision & Easy operation. Application Suitable for Engineering, Mining, Fabrication, Structural manufacturer, Profile cutting Industry, Jigs & Fixtures Manufacturer. Advantages Heavy Duty Cantilever design precise working & easy to movable facility with portable cnc cutting machine. Excellent cutting output, longitudinal rack & pinion drive. Flame can cut Mild steel, Carbon steel. Available Sizes 1000 x 2000mm, 1250 x 2500mm, 1500 x 2500mm & 1500 x 3000 mm

...more

Plasma Cutter

Plasma cutter that gas from the nozzle to the surface being cut, turning some of that gas to plasma. The plasma is sufficiently hot to melt the metal being cut and moves sufficiently fast to blow molten metal away from the cut.

...more

pipe cutting plasma machine

Pipe cutting plasma model of the portable cutting machine which realize both CNC Cutting & Pipe cutting process. It enjoys features of convenient, easy to handle, working stability & elegant appearance. Can make intersecting pipe hole cutting in different directions and different diameters. Can make branch pipe and main pipe vertical or cross in some angle. Can cut branch intersecting pipe's end socket for main pipe. Can cut square and slotted hole and all shapes on the pipe.Can cut dual bending ends for bending of the pipe after welding. 1) Equipped with “Two Axis Linkage Control” intersection. 2) NC System with 7”, 10.5” Color LCD Screen for pipe cutting without beveling. 3) Applicable for Flame & Plasma cutting process. 4) AC Stepper or Servo motor drive technology. 5) Input Power: Single Phase AC 220V, Approximately 600W. 6) Transmission: Rack & Pinion drive system. 7) Track Length: 2000mm (effective cutting length Y axis). can be customized for extending cutting length. 8) Applicable Pipe diameter: Φ60mm- Φ600mm. 9) Cutting Speed: 60-2000/ 5000mm/min. 10) Equipped with Fastpipe Nesting & cutting software.

...more

Pipe Cutting Plasma

Pipe cutting plasma model of the portable cutting machine which realize both CNC Cutting & Pipe cutting process. It enjoys features of convenient, easy to handle, working stability & elegant appearance. Can make intersecting pipe hole cutting in different directions and different diameters. Can make branch pipe and main pipe vertical or cross in some angle. Can cut branch intersecting pipe's end socket for main pipe. Can cut square and slotted hole and all shapes on the pipe.Can cut dual bending ends for bending of the pipe after welding. 1) Equipped with “Two Axis Linkage Control” intersection. 2) NC System with 7”, 10.5” Color LCD Screen for pipe cutting without beveling. 3) Applicable for Flame & Plasma cutting process. 4) AC Stepper or Servo motor drive technology. 5) Input Power: Single Phase AC 220V, Approximately 600W. 6) Transmission: Rack & Pinion drive system. 7) Track Length: 2000mm (effective cutting length Y axis). can be customized for extending cutting length. 8) Applicable Pipe diameter: Φ60mm- Φ600mm. 9) Cutting Speed: 60-2000/ 5000mm/min. 10) Equipped with Fastpipe Nesting & cutting software.

...more

Non Metal Laser Cutting Machines

Offering Non Metal Laser Cutting Machine. Non Metal Laser is most suitable and the preferred choice of equipments in industries such as advertisement, gifts, shoes, toys, and etc. Non metal laser is equipped with Texas 32 Bit DSP control system, there is a Flash memory on the mother board, you can downloadthe work file to the machine via USB cable.

...more

Laser tube cutting machines

Applicable Field Widely used for tubes and pipes processing, advertising trademark, advertising character, high/low voltage electrical cabinet, mechanism parts, kitchenware, cars, mechanical, metal craftwork, saw blade, electronic parts, eyeglasses, spring, circuit board, kettle, medical microelectronics, hard ware, knives tool, measurement, instrument, etc. Applicable Material Stainless steel, carbon steel, alloy steel, spring steel, aluminum, aluminum alloy, galvanized steel, cincalumzalutite, copper, silver, gold, titanium and other metal

...more

Laser Metal Cutting Machine

Laser metal cutting machine is most suitable and the preferred choice of equipments in industries such as advertisement, gifts, shoes, toys, and etc.

...more

Laser Cutting

Laser cutting is most suitable and the preferred choice of equipments in industries such as advertisement, gifts, shoes, toys, and etc.Non metal laser is equipped with Texas 32 Bit DSP control system, there is a Flash memory on the mother board, you can download the work file to the machine via USB cable.

...more

Flame Cutting Equipment

Flame cutting equipment the CNC Cutting machines series it can carry advanced technology and fill the gap of cutting machine. Meanwhile our CNC flame cutting machines have been using stably in many Industries like Metal Profile Cutting Industries, Heavy Fabrication Industries, Special Purpose machine Manufacturer, Jigs & Fixtures Manufacturer, Sheet Metal Industries, Agricultural Equipment manufacturing, Auto parts manufacturing Industry.

...more

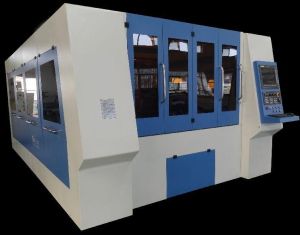

Fiber Laser Cutting Machines

1. Use imported optical components, good beam quality, high efficiency of Electro-optic conversion.2.High ratio between quantity and price, good reliability, long-term stability, fast speed, high efficiency, good economic returns, kerf small, cutting surface smooth.3. High cutting precision, can meet all requirements of sheet metal processing technology.4. Focal length automatic follow with cutting head, even if the material surface roughness and also can ensure cutting quality. kerf smooth, perfect, no need clean.5. Low operation cost, all material can be cut by air only (if need faster cutting speed, using oxygen.)6. Collecting trailer with wheel, lightweight design, easy to clean material.7. Powerful smoking device, solve question of metal processing dust and bad environment.8. Use Gantry mechanism, compact structure, no need take up large area.9. Imported linear guide rail, Panasonic servo drive, precision gear and rack, and let whole machine work perfect.10. All screw and guide rail and other motor with auxiliary lubrication system together, use centralized supply lubrication way, effectively ensure lifetime and working precision on each motor. Applicable Field Widely used for metalsheet processing, advertising trademark, advertising character, high/low voltage electrical cabinet, mechanism parts, kitchenware, cars, mechanical, metal craftwork, saw blade, electronic parts, eyeglasses, spring, circuit board, kettle, medical microelectronics, hard ware, knives tool, measurement, instrument, etc. Applicable Material Stainless steel, carbon steel, alloy steel, spring steel, aluminum, aluminum alloy, galvanized sheet, cincalumzalutite, pickling plate, copper, silver, gold, titanium and other metal sheet, pipes and tubes.

...more

Cnc Routers

CNC Woodworking Router adopt steel structure body, use Rack and Pinion and Linear Guide ways, are equipped with high speed water cooling spindle (or HSD air cooling spindle) and High speed stepper motor( or Japan Servo motor), advanced CNC control system, it is widely used for woodworking and Sign making. The software of M series Woodworking CNC Router is compatible with Type3/Artcam/UG/Pro-E/Mastercam/Ucancam V9 and so on. With CNC Wood Router, you can improve cutting and engraving quality, Increase production volume, Gain better material yields, Decrease overhead and Increase profits. Mass Cutting Systems offers a full range CNC Woodworking Machine, M-1325AT is a CNC Machining Center, it has automatic tool changer device (straight-line tools storeroom with 8 pcs tools).

...more

Cnc Profile Cutting Machine

cnc profile cutting machine developed by mass cutting systems as superxl series which is suitable for many industries for metal plate cutting. this machine is rigid gantry type design economical level solution for production of oxy fuel & plasma cutting process. This machine driven system with heavy duty track for steady and precision cutting.• longitudinal and transverse energy feed drag-chains, hose/ cable clean and move smooth.• direct rack and pinion of 1.5 module in both axes for accurate and repeatable motion.• plasma torch height sensing system with rapid initial height sensing.• high torque stepper motors 3.4nm, 6.8nm or 8.7nm capacity.• cnc controllers of 7” or 10.4” screen allows entering the program directly on the system or transfer files through usb.• gantry effective width available in 1.5, 2.0 & 2.5 meter in standard size. Effective length available from 3 meter – 12 meter.• variety of nesting software available for programming.• rapid speed 10mm – 6000mm/ min, cutting speed 10mm -2000mm/min.• maximum two torch stations available as per customer requirement.• lm guides for x axis movement for smooth & precision driving.• suitable for oxy fuel & air plasma cutting application.• oxy fuel cutting thickness 5mm – 150mm. Plasma cutting thickness as per selected air plasma model. users can select the units which has several optional functions such as automatic ignition, powder spraying lineation, cutting back, dynamic graphic tracking shows and so on. It realizes the whole cutting process automatic control.

...more

Cnc Plasma Cutting Machine

cnc plasma cutting machine is capable of cutting material much faster than oxy fuel, but plasma is only capable of piercing material up to 50mm thick. Plasma is also able to cut a larger range of material and transfers much less heat into material than oxy fuel. Often plasma cutting torches and oxy fuel cutting torches are mounted on the same cnc cutting machine to give the machine a larger range of processing thicknesses, for example 3mm – 150+mm. For most work plasma is more efficient than oxy fuel as 90% of steel cut is less than 50mm thick and if you were to compare some suitable plasma cutting system to an oxy fuel system it would process 50mm mild steel more than twice as fast. this machine is the heavy gantry in the standard mass cutting systems product line. The mhg series is designed for use with the latest technology in today’s precision plasma cutting systems as well as multi-head oxy-fuel applications. The high stiffness, precise linear guides in the transverse axis and heavy duty tracks guarantee the very best quality and a long duration of life. The leading edge of machine technology, incorporating the industry’s most reliable digital servo amplifiers, ac brushless motors, precision gearboxes equipped with machine, easily becomes the most productive part of your cutting operation. Fast oxy fuel cutting with integrated height sensing and ignition. Large structural steel tubing is welded together to form the end trucks and cross axis beam. Mating assembly surfaces are precision machined and ground for maximum accuracy. Precision gear rack insures repeatability and accuracy throughout the entire cutting process.

...more

cnc plasma cutter

CNC plasma cutter is formed through that gas from the nozzle to the surface being cut, turning some of that gas to plasma. The plasma is sufficiently hot to melt the metal being cut and moves sufficiently fast to blow molten metal away from the cut.

...more

cnc gas profile cutting machine

CNC gas profile cutting machine advanced technology and fill the gap of cutting machine. Meanwhile our CNC flame cutting machines have been using stably in many Industries like Metal Profile Cutting Industries,

...more

CNC Flame Cutting Machines

We, Mass Cutting Systems, have established ourselves as a renowned manufacturer and supplier of CNC Flame Cutting Machine as Super series. Successfully inventing the CNC Cutting machines series it can carry advanced technology and fill the gap of cutting machine. Meanwhile our CNC flame cutting machines have been using stably in many Industries like Metal Profile Cutting Industries, Heavy Fabrication Industries, Special Purpose machine Manufacturer, Jigs & Fixtures Manufacturer, Sheet Metal Industries, Agricultural Equipment manufacturing, Auto parts manufacturing Industry. Standard Features • Cutting width available 1.25 and 1.5 meter• Cutting length available from 2.0 meter to 3.0 meter• Longitudinal and transverse energy feed drag chains, hose/ cable clean and move smooth• DC Stepper drive amplifiers for years of maintenance free operation.• DC Stepper motors for wide speed range with accurate speed control• CNC controller allows entering the program directly on the system or transfer files through USB drive• Nesting software available for Programming• Single torch station available• Maximum machine speed: 5000 mm/min• Precision Linear Rail Drive Engagement• Adjustable steel mounting pads for adjusting height, level, straightness• Oxy Fuel Edge Prep Station - for straight line bevel cuts in either X or Y direction• Oxy fuel cutting thickness: 5 mm- 100mm

...more

Cnc Flame Cutting Machine

CNC flame cutting machine Longitudinal and transverse energy feed drag chains, hose cable clean and move smooth, DC Stepper drive amplifiers for years of maintenance free operation.CNC controller allows entering the program directly on the system or transfer files through USB drive. Adjustable steel mounting pads for adjusting height, level, straightness.

...more

cnc drilling machines

◆ automatically find pot to drill hole at x.y axis◆ four processing position, 12 hydraulic clamps, can clamp four sets of work pieces, and also can unload work pieces when drilling◆ self-controlled stroke drilling head, no need to set the thickness of work pieces and the length of drilling head, automatically finish the transfer of rapid feeding and work feeding.◆ cnc、plc system, crt display, programming based on windows platform with cad connection, fast and convenient programming, and visual previewing◆ automatic chip removal, coolant circulation cooling.◆ equipped with professional main shaft speed-reducing-motor from sew, germany.◆ key machine, hydraulic pressure, electric components are chosen from famous cooperation domestic and abroad.◆ optimized integration design for complete machine, no foundation requirements◆ the first choice equipment for the drilling processing of steel board. .

...more

cnc cutting machines

We could say that CNC is an electronic driver of the Cutting System based on the configurations by the user and the profiles of the parts to be worked on fed into the system before the beginning of the job. Making use of built-in electronic and software automation, CNC can control the cutting process calculating all available parameters, both the ones determined by the Cutting code (G-Code) fed into it beforehand and the real-time cutting data provided by the relevant sensors. It adjusts the proper gas mixture and velocity, the feed rate and the torch movement along the three axes, and the power of the Source. The cutting process is automatically continuously adjusted in the best way, much better than by the most experienced operator. CNC stands for Computed Numerical Control; CNC Machine is a machine which is controlled by a computer through a numerical program, this program is often in a format called G-code. G-code is also used on a wide variety of CNC machines such as Lathes and Mills. 2D profiling CNC machines can use Oxy-fuel (Gas), Plasma or Laser to sever material into almost any 2D shape by melting or vaporizing the material. This type of 2D profiling has been done by CNC machines in industry for over 25 years. The idea behind CNC cutting is to allow a computer to control the torch head making clean sharp cuts. Absolute precision is possible through CNC machining, consequently hand-held torches are to be avoided; the cutter has been built into the table. Fixed equipment as compared to portable ones has the option to include heavy cutting energy sources to cut much thicker material. They also allow opportunities for complex welding processes. More complex state-of-the-art technologies allow more elaborate cuts with thinner kerf and greater thickness. What is CAM? Computer-aided manufacturing (CAM) is the use of computer software to control machine tools and related machinery in the manufacturing of work pieces. Traditionally, CAM has been considered as a numerical control (NC) programming tool, wherein two-dimensional (2-D) or three-dimensional (3-D) models of components generated in CAD software are used to generate G-code to drive computer numerically controlled (CNC) machine tools. The marriage of CAM software and control systems is critical to the successful implementation of any CNC machine. An application for machining ‘sheet’ goods (metal plates, plastic sheets, thin woods, leather, glass etc.) should handle materials and sheets, it should be able to handle intricate Cutting Layouts, automatically place them on the sheet making optimal use of the raw material, permit manual intervention by the user regarding the best placement of the cutting layouts, generate the required code for inside and outside contours, pockets and drilling cycles, make any printouts needed by the operator and lastly but not least, make everything fast and keep records of the jobs done to be able to repeat them at any time in the future. Reliable CAM software should allow the nesting of parts and have features for copying, duplicating, rotating to angles of any degrees and mirroring parts to cut wastage to the minimum. It should also allow for parts to be aligned perfectly along the machine axes by automatically aligning the drawing to the actual part. Heavy Duty & Flexible Design CNC cutting machine is high speed, high accuracy cutting machine which features compact modular construction of heavy-duty tubular structure for easy and fast installation. Longitudinal drive and precise machine guiding profiles provide high cutting accuracy and contouring precision. It will accept a variety of cutting table, or customer can build their own. This machine is designed to grow with customer. Additional rail sections may be purchased with new system or added later in the field. Mass Cutting Systems Series Machine Delivers CNC cutting machines delivers full-featured and productivity at an affordable price. CNC Cutting machines by Mass Cutting Systems is the best value in the industry.

...moreBe first to Rate

Rate ThisOpening Hours