ergonomic material handling systems

Get Price Quote

We have a team of efficient personnel who sternly check the raw materials before final procurement. Thus, we ensure a qualitative array of products at customer's end. As our payment methods are practical and convenient, we are highly recommended by the clients. We provide option to pay in cash as well as through bank transfer.

Hydraulic Drum Lifter cum Tilter

Get Price Quote

1 Piece (MOQ)

Best Deals from Material Handling Equipments

Vibro shifter

Get Price Quote

Get in touch with us for placing small as well as bulk orders, timely deliveries will be straight to your doorstep! We are acknowledged for meeting the urgent requirements of the clients even on short notice as we are supported by capacious warehouse and streamlined inventory management system. Features: High-performance Robust construction Easy operations & maintenance

Material Handling System

510,000 - 2,500,000 Per NOS

1 piece (MOQ)

Hydraulic Hand Pallet Stacker

Get Price Quote

We are Manufacturer and Supplier of Hydraulic Hand Pallet Stackers that are of high quality. Hydraulic Hand Pallet Stackers are made in adherence with international standards and norms for safety and quality. We supply Hydraulic Hand Pallet Stacker at reasonable price. Hydraulic Hand Pallet Stackers are made available to the customers as per the requirement. These Hydraulic Hand Pallet Stackers are hard chromed, polished pistons that are unaffected by to rust, scratches and wear. They are easy to operate and have low-cost maintenance. Specifications : Load Carrying Capacity : 1000 kg. To 2500 kg. Available Lifting height : Single mast, Double masts, Triple masts from 200 mm-6000 mm Available Options : Manual, Electric Operated & Battery Operated Special Fork Length, Width, and Wheels & Capacity as Per Requirement. Highlights : Long lasting life Anti-corrosive Light and compact structure Easy to operate

ash handling systems

Get Price Quote

Fly Ash is the major constituent of the ash generated from Pulverized and Fluidized bed Coalfired boilers. The Fly ash gets collected at various points, with most of it in ESP hoppers. One of the methods for handling Fly Ash is Wet system in which the ash is mixed with water to form slurry which is pumped to slurry pit.

Customized Material Handling Equipment

Get Price Quote

We are offering a wide variety of Customized Material Handling Equipment. Our range of customized material handling equipment is manufactured using top quality materials which ensure that the equipment is high on performance, durability and sturdiness. The equipment is available in various models and is commonly used across engineering industry, foundries and other equipment handling units.

Material Handling Equipment

Get Price Quote

We are offering Material Handling Equipment.

metal gathering machine

Get Price Quote

We are offering metal gathering machine

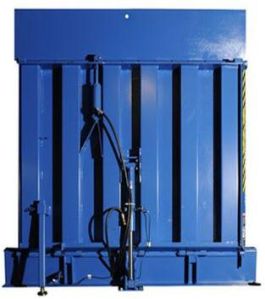

Vertical Storing Dock Leveler

210,000 Per Piece

1 Piece(s) (MOQ)

ash handling systems

Get Price Quote

We are indulged in manufacturing and supplying a wide array of Ash Handling. These are easy to maintain & operate and offer high performance. Moreover, these are fabricated in accordance with the predefined industrial norms & regulations. These provide plurality of hoppers that is disposed under a solid fuel-fired steam boiler. The hoppers have angled walls along with the rectangular opening regulated by a grate door. The air inlets are provided at intersections between adjacent angled walls so that the flow of ash can be facilitated along with the combustion of the unburned fuel. In addition, the hopper enters the crusher and is conveyed through the vacuum line to the disposal point. Moreover, the heavier ash particles are carried and the lighter particles are bypassed through the mobile tank truck.

Manual Roller Stacker

Get Price Quote

Asmita Engineering Equipments is technologically updated with what is required in the current market scenario, with this innovative and updated approach we bring to our clients Manual Roller Stacker.

Metal Pouring Ladle

50,000 Per Piece

Material Handling Systems

Get Price Quote

Our company is among the leading Material Handling Systems Suppliers. The Material Handling Systems, we manufacture, are used in automotive body shops, automotive paint shops and automotive final assembly systems. The machines are manufactured from highly durable raw materials, thus giving our machines an ability to stand the test of time. All the Automated Material Handling Systems, we offer are also thoroughly checked by our team of experts. We have tried to keep the manufacturing cost under strict control to ensure that our customers are always at the receiving end. ScrewRollerOverheadbeltChainTake offInclinedPacketCNC ManipulatorWire mesh beltPlastic beltbelt driven live rollerLine shaft rollerOverhead Pneumatic conveyor systemVibrating conveyor systemFlexible conveyor systemsSpecial Conveyor Solutions

yard ramp

450,000 Per Piece

Drum Lifter Cum Tilter

Get Price Quote

bulk material handling system

Get Price Quote

Belt conveyors are mostly used for handling bulk material such as bagasse, loose sugar,fertilizer, sand, bauxite, ash, mud, stone, crusher, hot mix plant, mines etc. Quality Engineers belt conveyors are more economic to suit with your requirementsand efficient in operation, performance. We are also taking the turnkey projects for power plant i.e for bagasse and coal handling, rice husk, cement, chemical plant, stone crusher.

Battery Operated Stacker

585,000 Per Piece

1 Piece (MOQ)

Drum Carrier

Get Price Quote

Working principle & features render’s drum trolley is designed for easy movement. carries drums of ms / plastic material by one person from one place to another godowns, production area, factories etc. For easy lifting & shifting the trolley is manufactured of m.s material with powder coating & wheels are polypropylene / casting / nylon / rubber / caster as per customer requirement.

metal gathering machine

Get Price Quote

Kejetherm Metal Gathering Machine is fully hydraulically operated with Resistance Heater. Principle of Operation Metal Gathering operation consists of heating the part of the job and pushing the remaining cold material of the job into hot zone till the required metal gathering takes place. Advantages By employing Metal gathering many of the well known technical limitations and disadvantages of mechnical upsetting can be overcomed. Simultaneous heating and forming in one machine. Almost unlimited gather in one operation. The mechanical upsetting limitation of about 3 x dia. no longer applies. The modern engine valve has an upset length of up to 20 x dia. and lengths of upto 40 x dia. are commonly electro-upset. No longitudinal flash is formed such as is unavoidable in a split-die mechanical upsettler. No waste of heating energy or material. Outside of the upset volume can be precisely controlled to allow subsequent, "flashless" forging in closed dies. Always ready for instant use, no warm up period. Energy efficient, about 0.35 - 0.40 kwh kg. Minimal scaling because of simultaneous heating and gathering. Improved die life in subsequent forging operations. No environmental pollution by emission of heat, fume or exhaust gas. Free upsets can be finished forged without re-heating and so save time and energy. Consistant heating temperature through the use of thyristor control. Optimal grainflow and fault free surface. The unheated bar length remains unchanged.