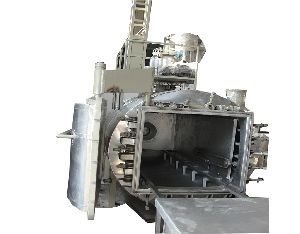

Epoxy Mixing Cum Casting Plant

Get Price Quote

Overview Resin casting is a method of casting where a mould is filled with a liquid synthetic resin, which then hardens. The synthetic resin for such processes is a monomer for making a thermosetting polymer. During the setting process, the liquid monomer polymerizes into the polymer, thereby hardening into a solid. Our resin casting plant is manufactured using quality components and spare parts to ensure optimum performance and long functional life. Resin casting plant is integrated with mixing chamber, which is designed with heating system with temperature controlling arrangement. The simplest method is gravity casting where the resin is poured into the mold and pulled down into all the parts by gravity inside a vacuum chamber. The casting is done in a vacuum chamber to extract the air which avoids formation of air bubbles. The mixing chamber with circular cone-shaped bottom is heated with an oil jacket, the temperature being measured and controlled continuously. The temperature of the wall is hence uniform. A stirrer with baffle rotating at the correct speed which gives shearing action causes thorough resin filler mixing. The agitation exposes all the mix to vacuum& thus degassing is thorough. The mixing paddle drive is with 3 phase motor & reduction gear. The shaft seal is robust rotary seal with tapered roller bearings. The pouring valve is made of P.T.F.E. (Teflon) & this makes cleaning easy. Trap is used to very effective stop abrasive filler particles from entering & ruining the vacuum pump. Features : Mixing chamber for mixing of resin, with hardener, accelerators, pigment and filters, of capacities from 5kg to 1000kg, designed for high vacuum degassing. It is designed with heating system having precise temperature controlling arrangement for controlling the exotherm during mixing, as required. Casting chamber, adequately sized to accommodate desired number of moulds, designed for pouring resin under high vacuum. Pouring system designed for vacuum casting with easy control and observation from outside, with specially designed PTFE valves. The plants can be offered continuous production process. Applications : CT and PT manufacturer Dry type transformer etc

Epoxy Mixing Cum Casting Plant

90,000 Per Piece

1 Piece (MOQ)

Best Deals from Mixing Plant

Epoxy Mixing & Casting Plants

Get Price Quote

In order to obtain void-free epoxy castings with low partial discharge and good du-electric strength suitable for use at high voltage it is necessary, among other things, to mix the resin & pre-dried filler well, to de-aerate it by vacuum and finally to pour it, also in vacuum. The mixing chamber with circular cone-shaped bottom is heated with an oil jacket, the temperature being measured and controlled continuously. The temperature of the wall is hence uniform. A stirrer with baffle rotating at the correct speed which gives shearing action causes thorough resin filler mixing. The agitation exposes all the mix to vacuum& thus degassing is thorough. The mixing paddle drive is with 3 phase motor & reduction gear. The shaft seal is robust rotary seal with tapered roller bearings. The pouring valve is made of P.T.F.E. (Teflon) & this makes cleaning easy. Trap is used to very effective stop abrasive filler particles from entering & ruining the vacuum pump. Water-cooled trap is provided for preventing volatile hardeners from entering the vacuum pump. Pouring chamber can be heated or unheated as required. Rotary turntable with vacuum-tight rotary seal or chain & sprocket driven trolley or rails allows the moulds to be positioned below the pouring spout without breaking vacuum. Epoxy mixing & de-aerating plant: Medium size epoxy vacuum mixing plant for use in the laboratories of a progressive Electrical Manufacturer can handle from 5 kg to 200 kg of Resin-filler gardner mix. It is very versatile being able to handle solid or liquid resins hot or cold processing. Temperatures fro 160oC to room temperature are possible. A vacuum of 1 torr is easily obtained. the use of the plant enables void-free castings to be obtained. Our Team The reason behind the success and growth of our organization is the support of our competent team of experts. These professionals have industry expertise of many years and posses a thorough knowledge in their respective domains. We make sure that the professionals are regularly trained to keep them updated about the market scenario. The team consists of the following: Technicians Quality controllers Research & development associates Sales & marketing executives With the united and tenacious efforts of these professionals, we ensure that the products offered by us are in compliance with the needs of our clients.

Resin Mixing And Pouring Plant

Get Price Quote

Resin casting is a method of casting where a mould is filled with a liquid synthetic resin, which then hardens. The synthetic resin for such processes is a monomer for making a plastic thermosetting polymer. During the setting process, the liquid monomer polymerises into the polymer, thereby hardening into a solid.

Mixing Pilot Plant

300,000 Per Piece

Epoxy Mixing And Casting Plant

Get Price Quote

We are counted amongst the foremost Manufacturers and Suppliers of Epoxy Mixing And Casting Plants which are highly demanded in the market. We have gained expertise in this field and offer efficient Epoxy Mixing And Casting Plants. These Epoxy Mixing And Casting Plants are manufactured from superior quality raw materials and components which impart strength and durability. We offer our Epoxy Mixing And Casting Plants at economic prices. Capacity from 20kg to 500kg The Plant Consist of Mixing Chamber (M.S or S.S)Shroud box assemblyPouring chamberVacuum pumping systemControl console Mixing Chamber Mixing of resin hardener with accelerator will be done thoroughly by anchor type stirrer with stationary blade rotating at speed 70 � 80 RPM. The mixing chamber is surrounded by oil heating jacket with precise temperature controlling arrangement. Water jacket is provided surrounding to heating jacket for chamber cooling as required. Shroud Box This unit connects mixing chamber and pouring chamber in which Teflon ball and Sleeve arrangement is provided for pouring the mix under vacuum into moulds in pouring chamber. Pouring Chamber (Insulate) Chamber shape : Cylindrical or RectangularHeating : Air heating to prevent heat loss during pouringDoor : Circular or RectangularDesigned to : Vacuum and also desired pressure as requiredIsolating valve between mixingChamber and pouring chamber : A special type gate value of sai guru make.Rotating cone : By geared wheels rotating 360 degreeTrolley : Adequate capacity trolley with moving arrangementTemperature Indicator : Digital Type Vacuum Pumping System A designed vacuum pumping system by rotary oil sealed pump or combination of roots Rotary vacuum pumps are adopted and connected to mixing chamber , shroud box and pouring chamber through effective hardner cum particle trap by 100% leak proof valves of our own make. Control Console Necessary electrical instrumentation with digital display of temperatures, emergency stop button equipped accessibly for easy operationA mimic diagram provided on control panel for viewing various functioning of events Accessories A suitable platform railing and paras ladder provided for suitably for easy workingSet of Spares will be given with the plant

epoxy mixing plant

4 Per Piece

Concrete Mixing Plant

Get Price Quote

Concrete Mixing Plant, Concrete Mixer Machines, Hydraulic Bar Cutting Machine

Asphalt Drum Mixing Plant

Get Price Quote

road construction machinery burner parts, Road Construction Equipment

Resin Mixing And Pouring Plant

Get Price Quote

Resin Mixing And Pouring Plant, PCB Treatment Plant, Lube Oil Purifier Plant

rubber mixing plant

Get Price Quote

rubber mixing plant, Plastic Molding, Rubber Mixing Machine

Epoxy Mixing Casting Plants

Get Price Quote

Epoxy Mixing Casting Plants, Vacuum Impregnation Plant

epoxy mixing plant

Get Price Quote

epoxy mixing plant

mixing plant

Get Price Quote

mixing plant, Dehydration plant

mixing plant

Get Price Quote

mixing plant, Concrete Plant