Vickers Hardness Testers

(Model : VM-50 ) Testing range is very wide, from soft metal such as lead, upto the hardest, like hardeness steel. Same hardness number is obtained on the same specimen, regardless of the load applied. The indication is tiny and allows testing of a precision finished part. Loading and unloading cycle is motorised. Thin sheet metal is perfectly tested because the load applied is very small. Built - in projection screen to get accurate results. Specifications : 'Vickers Hardness Tester is a simple and accurate means to produce and measure the diamond indentation. These testers are suitable for measuring the hardness of precision metallic parts with wide testing range from soft to hard and their accurate results are widely acclaimed. These testers strictly conform to IS : 1754 and ISO 6507-2. Number of special acceessories are available on request and as per special requirement. Construction : The robust machine frame is designed to accommodate the high precision loading system and an optical projection screen. Specimen is placed on a testing table. The test cycle is fully automatic. The accurate load is applied on a diamond penetrator by means of a lever and weights. After a specific lapse of time, the load is removed automatically. The objective is indexed with the test piece and the diamond indentation is projected on the measuring screen. The diagonals of the indentation can be measured by means of the micrometer screw of the projection screen.

...more

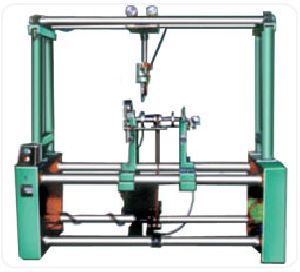

Vertical Balancing Machine

Machines Model HDVTM are Vertical type single plane hard Bearing Balancing Machine provided with Microprocessor based measuring panel HDVM – 8500 for balancing Disc shaped Rotors such as Clutch Plates, Fan Blades , Fly Wheels, Magnetos, Grinding Wheels, Impellers etc. Where as HDVTM are vertical type two plane Hard Bearing Machines provided with Microprocessor based measuring panel HDVTM – 8500 for balancing spinning pots, Spinning spindles etc. Both type Machines feature a very simple operation. The working cycle is fully automatic From safety point of view a double press push button starts machine, measures, and stores the unbalanced values on DPMS and stops machine. Keyboard facility provided on measuring panel for correct Data feeding of Rotor with one digit accuracy for its dimensions like ‘RAD’, +1, for single plane & w, d, r1, r2, +11, +12 for two plane machines. When Rotor is balanced within the limits respective LEDs glow up, indicating no further correction is necessary. For other details please refer standard features of measuring panel HDVM and HDVTM. Both type of machines are provided with electronic companion software to comensate the unbalance effect due eccentricity between rotating ( Spindle ) axis & adaptor (Rotor) axis. Standard Features : A. Standard Features of 'HDVM-8500 & HDVTM-8500' : 1) Digital display for unbalance indication : Amount and angle of unbalance for both planes displayed on separate DPMs for HDVTM M/c. Hence linear accuracy is very good as compared to analog meter. Accuracy + 1 digit for amount and + 1 degree for angle. 2) Digital display for RPM indication : A DPM is provided to indicate balancing speed continuously as a standard feature. 3) Auto Stop : No necessary to stop machine once started. It stops automatically after stabilization of unbalance results. 4) Simultaneous Indication : Amount and angle of unbalance in both planes displayed simultaneously and remains displayed (stored ) till next run. This totally eliminates operation of plane selector and reduces additional time for stabilization of readings in other plane. 5) Key-Board : Data of rotor dimensions and balancing tolerance i.e. values of A, B, C, R1, R2, tl1, tl2 are fed by key operation. Hence accuracy of data feeding is accurate up to 1 digit. 6) Tolerance Indicators : Separate LEDs are provided for both planes which glow when unbalance is reduced within balancing tolerance. 7) Auto Range : Depending upon whether unbalance amount is more or less a respective course or fine range gets automatically selected till rotor gets balanced within tolerance limits, Multiplier operation is totally eliminated. 8) Data store : Data of various rotors can be stored against respective rotor type nos. Hence no need of measuring of rotor dimensions or rotor data feeding when repeat balancing operation required. Just call rotor type no. and machine is ready for balancing. 9) Self Check : Panel is provided with ‘self-check’ mode which checks proper functioning of digital displays, LEDs is cyclic operation. This helps immediate fault detection. B. Additional Features on demand for Unbalance correction (Optional) : 1. Vertical drilling attachment with drilling – thrust compensation. 2. Horizontal drilling attachment with drilling thrust compensation. 3. Welding attachment. 4. Any other attachment as per customers requirement. C. Printer : A matrix printer can be connected through available ‘FIE’ software. D. Compensation Indication : ‘FIE’ software specially developed with 3 – 99 component indication, is suitable for balancing of rotor with fixed locations for balancing correction. Technical Specifications : Vertical Hard Bearing Balancing Single / Two Plane Dynamic Balancing Machine

...more

Universal Testing Machines

• Loading accuracy as high as + 1%.• Suitable at variable speeds to suit a wide range of materials• Continuous roll autographic recorder supplied as standard to enable study of the behavior of materials • Motor driven threaded columns for quick effortless adjustment of middle crosshead to facilitate rapid fixing of test specimen.• High reading accuracy due to large size and design of dial• Wide range of standard and special accessories, including load stabilizer.• Easy change from plain to threaded and screwed specimens.• Large effective clearance between columns enables testing of standard specimens as well as structures.• Simple controls for easy of operation.• Robust straining frame of an extremely rigid construction.• Safe operation ensured be means of safety devices. Application : Universal Testing Machine is designed for testing metals and other materials under tension, compression bending, transverse and shear loads. Hardness test on metals can also conducted. Principal of Operation : Operation of the machine is by hydraulic transmission of load from the test specimen through pressure transducer to a separately house load indicator. The system is ideal since it replaces transmission of load through levers and knife edges, which are prone to wear and damage due to shock on rupture of test pieces. Load is applied by a hydrostatically lubricated ram. Main cylinder pressure is transmitted to the cylinder pressure is transmitted to the cylinder of the pendulum dynamometer system housed in the control panel. The cylinder of the dynamometer is also of self-lubricating design. The load transmitted to the cylinder of the dynamometer is transferred through a lever system to a pendulum Displacement of the pendulum actuates the rack and pinion mechanism which operates the load indicator pointer and the autograpic recorder. the deflection of the pendulum represents the absolute load applied on the test specimen Return movement of the penulum is effectively damped to absorb energy in the event of sudden breakage of a specimen Machine consists of Straining Unit : This consists of a hydraulic cylinder motor with chain and sprocket drive and a table coupled with the ram of the hydraulic cylinder, mounted on to a robust base. The cylinder and the ram are individually lapped to eliminate friction. The upper crosshead is rigidly fixed to the table by two straight columns.The lower cross head is connected to two screwed columns which are driven by a motor. Axial loading of the ram is ensured by relieving the cylinder and ram of any possible side loading by the provision of ball seating.An enlogation scale with a minimum graduation of 1mm, is provided to measure the deformation of the specimen.Tension test is conducted by gripping the test specimen between the upper and lower cross-heads and the table.The lower cross-head can be raised or lowered rapidly by operating the screwed columns, thus facilitating ease of fixing of the test specimen. Control Panel : The control Panel consists of a power pack complete with drive motor and an oil tank, control valves a pendulum dynamometer, a load indicator system and an autographic recorder Power Pack : The power pack generates the maximum pressure of 200 kgf/cm2. The hydraulic pump provides continuously non-pulsating oil flow. Hence the load application is very smooth. Hydraulic Controls : Hand operated wheels are used to control the flow to and from the hydraulic cylinder. The regulation of oil flow is infinitely variable. Incorporated in the hydraulic system is a regulating valve, which maintains a practically constant rate of piston movement. Control by this valve allows extensometer readings to be taken. Load indicator System : This system consists of a large dial and a pointer. A dummy pointer is provided to register the maximum load reached during the test. Different measuring ranges can be selected by operating the rangee selection knob. An overload trip switch is incorporated which, automatically cuts out the pump motor when the load range in use is exceeded. Pendulum Dynamometer : This unit permits selection of favourable hydraulic ratios producing relatively small frictional forces. Pressurised oil in the loading cylinder pushes up the measuring piston proportionately and actuates the special dynamometer system. The Piston is constantly rotated to eliminate friction. The dynamometer system is also provided with an integral damper and ensures high reliabilty of operation. The load transmitted to the dynamometer is transferred through a pendulum to the load indicator Accuracy and Calibration : All Electronic Universal Testing Machines are closely controlled for sensitivity, accuracy and calibartion during every stage of manufacture. Every machine is then calibrated over each of its measuring ranges in accordance with the procedure laid down in British standards. 1610 : Part1 : 1992 and IS : 1828 : Part1 : 1991.Electronic Universal Testing Machine comply with Grade "A" of BS : 1610 : Part1 : 1992 and class 1 of IS-1828-Part-1:1991. An accuracy of +1% is guaranted from 2% to 100% of the capacity of the machine. Below 20% of the selected range, the maximum permissible error is 0.2% of the full load reading. Autographic Continuous Roll Load-Elongation Recorder: This unit is of the pen and drum type and is supplied as standard. The horizontal motion of the pen products the ordinate of the diagram and the drum rotation products the extension ordinates, in the ratio of either 1:5 or 1:10 A continuous roll of graph paper is stored inside the drum and is easily replaced

...more

Universal Tensile Testing Machine

Suitable for tensile test of non ferrous metals, wires, cables, wood, plastic, rubber, paper, resin, fabrics etc. Load Range from 200 N to 50 kN. Available in dial type, digital and computerised models. Computer controlled Universal Testing Machine with ball screw is available with 1 kN to 100 kN capacity. Accuracy confirms to IS 1828 BS 1610.

...more

Tensile Testing Machine

Suitable for tensile test of non ferrous metals, wires, cables, wood, plastic, rubber, paper, resin, fabrics etc. Load Range from 200 N to 50 kN. Available in dial type, digital and computerised models. Computer controlled Universal Testing Machine with ball screw is available with 1 kN to 100 kN capacity. Accuracy confirms to IS 1828 / BS 1610.

...more

Shock Absorber Field Testing Machines

• It is used for on site verification of Shock Absorbers at dealers end. • It improves dealers service as he is in a position to give quick feedback on the part performance.

...more

Rockwell Hardness Testers

Features : Rockwell, Rockwell Brinell Combined, Rockwell / Rockwell Superficial Combined System Hardness Testers. Hardness Testers, Model RAS, RAB-1, RAB-250, TWIN are manually operated. All these models are suitable for testing hardness of metals sand alloys of all kinds hard or soft, whether flat, round, or irregular shape. These testers are simple in design and easy to operate, yet sensitive & accurate. Various models from the wide range are suitable for schools, laboratories, tool-rooms, inspection, heat treatment departments, factories etc.These testers strictly confirms to IS : 1586 - 2000, ASTM : E 18 for Rockwell Superficial Test and IS : 2281 - 2005, ASTM : E 10 for Brinell test.

...more

microhardness tester

Computerised Microvickers Hardness Tester is a simple and accurate means to produce and automatically measure the diamond indentation to give micro hardness numbers directly. These testers are suitable for measuring the hardness of precision metallic parts with wide testing range - from soft to hard, and their accurate results are widely acclaimed. These testers strictly conform to IS:1754:2002 and ISO 6507-2:1997. Construction : The machine frame is designed to accommodate the high precision loading system. Specimen is clamped by vice or supported by proper fixtures. The test cycle is fully automatic. The accurate load is applied on a diamond indentor by means of dead weights. After a lapse of time, the load is removed automatically. The image id digitallized using a CCD Camera fitted on the machine and is captured by the PC. The diagonals of the indentation are measured by the PC and the Micro Hardness number is displayed directly on monito

...more

Micro Hardness Tester

Computerised Microvickers Hardness Tester is a simple and accurate means to produce and automatically measure the diamond indentation to give micro hardness numbers directly. These testers are suitable for measuring the hardness of precision metallic parts with wide testing range - from soft to hard, and their accurate results are widely acclaimed. These testers strictly conform to IS:1754:2002 and ISO 6507-2:1997. Construction : The machine frame is designed to accommodate the high precision loading system. Specimen is clamped by vice or supported by proper fixtures. The test cycle is fully automatic. The accurate load is applied on a diamond indentor by means of dead weights. After a lapse of time, the load is removed automatically. The image id digitallized using a CCD Camera fitted on the machine and is captured by the PC. The diagonals of the indentation are measured by the PC and the Micro Hardness number is displayed directly on monitor.

...more

Metallurgical Microscopes

We supply all types of metallurgical microscopes including inverted / erect stage. Magnification: Max. up to 900 X Computer interface attachment to get instant photographs. Powerful image analyzer software can be supplied with above attachment.

...more

Mechanical and Electronic Extensometer

Mechanical Extensometer It is essential to measure the elongation of test specimen under load, to have it's mechanical properties. FIE Extensometer Model EM-1 is intended to serve the above purpose. Construction & Application : This consists of two long knife edges at top, two dial indicators and lower knife edges to actuate the dials. The bars are pressed against the speciman by means of clamps So that the knife edges bite the specimen to avoid any slip. The upper edges are adjustable to provide different guages lengths for measurement. As deformation takes place the lower knife edges transfer the movement to the dial guages and the deformation of specimen is shown on dials, so that the change in length of specimen by 1/100mm, equals to one division of the graduation on dial.

...more

Leak Detection Setup for Cylinder Head

• We provide such set ups & complete systems for leak detection. • This is required for Cylinder Heads, Cylinder Blocks, Tubes, Enclosures, Silencers etc.

...more

Leak Detection Cylinder Head

Type : leak detection.

Lathe tool dynamometer

• It is a Educational Aid. • It indicates that we also undertake such Educational Aid related development projects.

...more

impact testing machines

The pendulum Impact Tester, Model IT-30 is designed for conducting Izod, Charpy test. The test methods confirm to BS : 131 : Part 4-1972 (Amended 15 Aug. 1993) BSEN : 10045-2 : 1993 & ASTM : E-23-94a. The Pendulum is mounted on antifriction bearings. It has two starting positions, the upper one for Charpy & the lower one for Izod testing. On release, the pendulum swings down to brake the specimen and the energy absorbed in doing so is measured as the difference between the height of drop before rupture of the test specimen and is read from the maximum pointer position on the dial scale. (It is read on digital readout in case of electronic machines.)There are two strikers and one combined support available for fitting in to the pendulum and on to the base of the machine for the Izod, Charpy test respectively, Changing from one striker to another is achieved simply by fixing the new striker into it's position. Charpy Test : The charpy test piece rests on alloy steel support anvils, fitted on the base of the machine rigidly held in position by Allen screws. End stopper is provided for quickly and accurately locating the test piece centrally between the supports. Izod Test : The Izod test is clamped vertically in Izod support fitted on the base of the machine. The support is provided with a machined vertical groove to suit the test piece size. The front clamp piece and the Allen screw enable clamping of the test piece in correct height with the help of Izod setting gauge supplied. This impact tester offered with 300J energy exclusively for Charpy test confirming to ASTM E-23. This machine is geometrically checked in the works to the more stringent requirements of the American standard. The accuracy of the machine is then verified by PROOF TEST by testing standard test specimens supplied the NIST, USA. Two sets ( Low & high energy-1 Set (4 Nos.) each.) must agree with the normal values within certain tolerance specified. Optional Accessories For IT 30 / IT 30 D : Caliper gauge for checking V notch for Izod & Charpy. Templates for checking 10 x 10 mm cross section of Izod / Charpy test specimen. Depth notch gauge including V & U notch gauges for checking depth below V/U notch, angle and radius. Izod support for 0.450" dia Izod round specimen. Self centering tong for quick and accurate setting of Charpy test specimen. 'V' notch milling cutter. 'U' notch milling cutter.

...more

hardness testing machines

For Rockwell, Rockwell Superficial & Brinell Testing) Principal : Rockwell & Rockwell Superficial tests consists of forcing an indentor (Diamond or Ball) into the surface of a test piece in two steps i.e. first with preliminary test force and thereafter with additional test force and then measuring depth of indentation after removal of additional test force (Remaining preliminary test force active) for measurement of hardness value.Brinell test consists of forcing a hardened ball into surface of a test piece with a specified test-force and measuring the diameter of indentation for evaluation of Brinell hardness number. Operation : For Rockwell & Rockwell Superficial Test : In case of 'RASN' series machines for Rockwell & Rockwell superficial tests a preliminary test force in first applied and then indicator is automatically set for zero. Quickly thereafter an additional test force is applied without removing the preliminary test force. When the penetration is stabilised, the additional test force is removed and the hardness number is shown directly on the indicator. For Brinell Test : The operation is exactly same as above. However, the diameter of impression is measured outside of machine by Brinell microscope. Brinell hardness number is found out by referring corresponding hardness tables showing hardness number against dia. of indentation for specified ball diameter and test force. Rockwell System Hardness TesterModel : RASN• Suitable for Rockwell Tests.• Manually Operated.• Preliminary Test Force - 98.07 N (10kgf).• Additional Test Force - 490.3, 882.6, 1373N (50.90, 140 kgf).• Total Test Force - 588.4, 980.7, 1471N (60, 100, 150 kgf).• Test Force Selection by external dialing.• Auto zero setting dial gauge. Rockwell cum Brinell Tester, Model RASN (B)• Same as RASN above in additional• Additional Test Force - 1471, 2354N (177.5, 240 kgf) • Total Test Force - 1839, 2452N (187.5, 250 kgf) 'RASN' series of Hardness Testing Machines come with much improved design and look with following major design changes. The machine body is having a taper front look and a big size dial gauge in the front. The machine is powder coated for far better look. The paint shade do not fade and machine looks like new over year. The elevating screw of machine is guided in a hardened and ground bush, not allowing movement of elevating screw more than 0.05 mm when raised to full height. The accessory is returned for years together due to hardened bush. A hardened and ground stepped bush is fixed on top of main screw for location and rest surface. This guarantees no change in results due to rough handling of test table or test piece. It means a trouble free long life machine accuracy. An antifriction linear bearing with almost no clearance is provided for a perfect vertical movement of loading plunger with minimum friction. This enable testing of small dia. pin or ball upto 3 mm dia. All machine models are provided with automatic zero setting dial gauge or digital readout. Hence zero setting at every test is avoided. All four models confirm to respective standard as under. • IS : 3804, BS 10109-2 & ASTM E-18 for Rockwell Test. • IS : 5073, BS 10189-2 & ASTM E-18 for Rockwell Superficial Test. • IS : 2281, BS 10003-2 & ASTM E-10 for Brinell Test. Rockwell Cum Rockwell SuperficialHardness Tester Model : RASN ( T ) • Suitable for Rockwell & Rockwell Superficial Tests.• Manually Operated.• Preliminary Test Force - 29.42, 98.07N (3, 10kgf).• Additional Test Force - 177.7, 264.8, 411.9, 490.3, 882.6, 1373N (12, 27, 42, 50, 90 & 140 kgf).• Total Test Force - 147.1, 294.2, 441.3, 588.4, 980.7, 1471N (15, 30, 45, 60,100, 150 kgf).• Test Force Selection by external dialing.• Auto zero setting dial gauge. Motorised Rockwell System Hardness Tester Model : RASN ( M ) • Suitable for Rockwell Tests.• Motorised for automatic Operation cycle i.e. load / dwell / unload.• Preliminary Test Force - 98.07N (10kgf).• Additional Test Force - 490.3, 882.6, 1373N (50, 90, 140 kgf).• Total Test Force - 588.4, 980.7, 1471N (60, 100, 150 kgf).• Test Force Selection by external dialing.• Auto zero setting dial gauge. Optional Accessories : • Steel Ball Indentor 1/8", 1/4", 1/2"• Testing Table 200mm dia.• Testing Table 70mm dia. with 'V' groove for round jobs 10 to 80mm dia.• Vari-rest to support odd shaped jobs.• Jominy test fixture for end quench test.• Gooseneck Adopter No.1• Special Diamond Indentor suitable for Gooseneck Adopter No.1• Short nib diamond indentor suitable for Gooseneck Adopter No. 1• Gooseneck Adopter No. 2 • Special Diamond Indentor suitable for Gooseneck Adopter No.2• Gooseneck Adopter No. 3 • Raised centre testing table 15mm dia.• Diamond spot anvil.• Cylindron anvil for testing big jobs above 20mm dia.• Eyeball anvil with 25.4mm dia or 38mm dia. ball• Gooseneck anvil for pipes 5 to 25mm ID with 5mm step inserts• Jack rest for long and heavy jobs.

...more

Hardness Testing Machine

Principal : Rockwell, Rockwell superficial & Rockwell cum Brinell tests consists of forcing an indentor (Diamond or Ball) into the surface of a test piece in two steps i.e. first with preliminary test force and thereafter with additional test force and then measuring depth of indentation after removal of additional test force (Remaining preliminary test force active) for measurement of hardness value.RASNE series machines are suitable for Rockwell, Rockwell superficial & Rockwell cum Brinell tests. These are motorized digital Hardness testers having LCD display for easy hardness measurement. The results are displayed in 0.1 Rockwell unit for more accurate measurement. Operation : Various parameters of test can be set on front panel by operation of key board and observing LCD display Viz high/low limits, dwell time, auto / manual start, printer selection, scale selection etc. All set data can be verified edited by pressing SCL key one after another.Machine operation is very simple. The normal mode is a bar followed by "SET" indication. Raise elevating screw slowly through bar indication till "SET" position which will show "PRESS START" indication. Now press "START" button. Loading/unloading cycle will be completed and hardness is shown on LCD display with High / Good / Low indication. Lower down elevating screw. Panel will show normal mode for next test. Also when required 'AUTO START' on front panel by operation of key board & observing LCD Display then raise elevating screw slowly through bar indication till "SET" position then it will starts loading / unloading cycle automatically & hardness is shown on LCD Display with High / Good / Low indication. 'RASNE' series of Hardness Testing Machines come with much improved design & look with following major design changes. This is motorized machine having automatic loading/unloading cycle suitable for production testing. The machine body is having a taper front look and a large size read-out in the front. The machine is powder coated for better look. The paint shade do not fade and machine looks like new over year. The elevating screw of machine is guided in a hardened and ground bush, not allowing movement of elevating screw more than 0.05 mm when raised to full height. The accessory is retained for years together due to hardened bush. A hardened and ground stepped bush is fixed on top of main screw for location and rest surface. This guarantees no change in results due to rough handling of test table or test piece. It means a trouble free long life machine accuracy. An antifriction linear bearing with almost no clearance is provided for a perfect vertical movement of loading plunger with minimum friction. This enables testing of small dia. Pin or ball upto 3 mm dia. These models are provided with automatic working cycle and digital LCD display with 0.1 Rockwell resolution. This insures productivity with better accuracy. IS:1586:2000 for Rockwell and superficial test. IS:2281:2005 for Brinell Hardness Test. Note : For Brinell scale - manually select (187.5 or 250 kgf) with respected ball indentor. At that time take reference of set point only. Apply the load, then measure the impression dia by Brinell microscope only. (No Brinell scale display on screen). Optional Accessories : • Steel ball indentor 1/8", 1/4", 1/2". • Testing Table 20mm dia. • Testing Table 70mm dia. with 'V' groove for round jobs 10 to 80mm dia. • Vari-rest to support add shaped jobs. • Jominy test fixture for end quench test. • Gooseneck Adoptor No.1. • Special diamond indentor suitable for Gooseneck Adoptor No.1. • Short nib diamond indentor suitable for Goodseneck Adoptor No.1. • Gooseneck Adoptor No.2. • Special diamond indentor suitable for Goodseneck Adoptor No.2.• Gooseneck Adoptor No.3. • Raised center testing table 15mm dia. • Diamond Spot Anvil. • Cylindron anvil for testing big jobs above 20mm dia. • Eyeball anvil with 25.4mm dia. or 38mm dia. ball. • Gooseneck anvil for pipes 5 to 25mm ID with 5mm step inserts. • Jack rest for long and heavy jobs.

...more

electronic universal testing machines

• Motorised Control Valve.• Load accuracy as high + 1%.• Straining at variable speeds to suit a wide range of materials.• Printer & PC graphs enable study the behavior of the material.• Motor driven threaded columns for quick effortless adjustment of middle crosshead to facilitate rapid fixing of test specimen.• Simplicity in reading because of digital readouts.• Wide range of standard and special accessories.• Easy change from plain to threaded and screwed specimens.• Large effective clearance between columns enable testing of standard specimens as well structures.• Simple controls for ease of operation.• Robust straining frame of an extremely rigid construction.• Fully enclosed and protected pressure transducer.• RS 232 serial port for PC control of m/c. Application : Electronic Universal Testing Machine is designed for testing metals and other materials under tension, compression bending, transverse and shear loads. Hardness test on metals can also conducted. Principal of Operation : Here UTM Right Control Valve is Servo Controlled in close loop mode as per mode selection. Following control modes available :1) Standard Manual Control2) Potentiometric Control3) Load Rate Control4) Elongation Rate Control5) Load Hold Mode6) Strain Rate Control Also Auto Start, Potentiometric start & Initial Valve open start options are available for test to take care of slippage & different specimen types. Load is applied by hydrostatically lubricated ram. Main cylinder pressure is transmitted to the pressure transducer housed in the control panel. The transducer gives the signal to the electronic display unit, corresponding to the load exerted by the main ram. Simulteniously the digital encoder fitted on the straining unit gives the mechanical displacement. Machine consists of : Straining Unit : This consists of a cylinder motor with chain and sprocket drive and a table coupled with the ram of the hydraulic cylinder, mounted on to a robust base. The cylinder and the ram are individually lapped to eliminate friction. The upper cross-head is rigidly fixed to the table by two strenthened columns.The lower cross - head is connected to two screwed columns which are driven by a motor. Axial loading of the ram is ensured by relieving the cylinder and ram of any possible side loading by the provision of ball seating.An displacement scale with a minimum graduation of 1mm, is provided to measure the deformation of the specimen.Tension test is conducted by gripping the test specimen between the upper and lower cross-heads.Compression, transverse , bending, shear & hardness tests are conducted between the lower cross-head and the table.The lower cross-head can be raised or lowered rapidly by operating the screwed columns, thus facilitating ease of fixing of the test specimen. Control Panel : The control Panel consists of a power pack complete with drive motor and an oil tank, control valves and electronic display unit. Power Pack : The power pack generates the maximum pressure of 200 kgf/cm2. The hydraulic pump provides continuously non-pulsating oil flow. Hence the load application is very smooth. Hydraulic Controls : Hand operated Release Valve & motorised control valve are used to control the flow to and from the hydraulic cylinder. The regulation of the oil flow is infinitely variable. Incorporated in the hydraulic system is a regulating valve, which maintains a practically constant rate of piston movement. Control by this valve allows extensometer reading to be taken. Electronic Control Unit : (FIE- SERVO) - In Electronic panel 8085 microprocessor is used for basic UTM operation & an 8 bit dedicated microcontroller is used for close loop & Servo Control.- Panel is having parallel printer port, RS 232 C serial port for PC interface.- 2 lines x 8 digits 7 segment display & membrane keyboard for data entry.- 20 data sets and 50 results storage. Software : Windows based basic software for Servo Control is in standard scope of supply. • Real Time graph, User friendly software. • Extensive graphics on screen for curve plotting, magnification and zooming.• Software features include Graph comparison, point tracing facility. Different units selection for load & displacement.• Statistical evaluation with water fall dig., Mean deviation, frequency distribution, Skew dig., Histogram. Also calculates max. value, min.value, Mean Value, Variance, Standard Deviation. (Other statistical parameters on request). Selectable batch & statistical printouts.• Evaluation of wide range of user selectable parameters such as % elongation, % reduction in area, young's modulus, yield stress, proof stress etc.• Optional Software packages for Extensometer, Shear Bend, Torsion, Rubber, Textile testing etc. Accuracy and Calibration : Electronic Universal Testing Machines are closely controlled for sensitivity, accuracy and calibartion during every stage of manufacture. Every machine is then calibrated over each of its measuring ranges in accordance with the procedure laid down in British standards. 1610 : Part1 : 1992 and IS : 1828 : Part1 : 1991.Electronic Universal Testing Machine comply with Grade "A" of BS : 1610 : Part1 : 1992 and class 1 of IS-1828 - Part - 1:1991. An accuracy of +1% is guaranted from 2% to 100% of the capacity of the machine. Below 20% of the selected range, the maximum permissible error is 0.2% of the full load reading.

...more

dynamic balancing machines

with Microprocessor Based Measuring Panel ( Hard Bearing Model - HDCM ) Machines model HDCM are belt driven horizontal type photo scanning Universal Hard Bearing Balancing Machine, provided with microprocessor based measuring panel HDCM – 8500 suitable for balancing different shapes of rotors, of electrical machines, Cylinders, fly wheel, rotor of centrifugal pumps and other type of rotating machines. These machines are very simple in design. No drive coupling / adaptor etc. required to connect to the rotor to be balanced. It has following advantages - Cost saving on manufacturing of precision adaptor to connect drive coupling to rotor. Any rotor can be balanced without losing time in manufacturing of adaptor. The balancing accuracy of rotor not disturbed due to unbalance in drive coupling / adaptor. Belt drive machine are more accurate (about 5 times) as compared to end drive machine. The machines features a very simple operation. The working cycle is fully automatic. From safety point of view a double press push button starts machine, Measures and stores the unbalance values on DPMs for two Plane simultaneously and stops machine. Key board facility provided in measuring panel for correct data feeding of rotor with 1 digit accuracy for its dimensions like A, B, C, R1 & R2. Tolerance limits of both correction planes i.e. +11 & +12 can be feed so that when rotor is balanced within the limits respective LEDs glow up, indicating no further correction necessary. For other details please refer “ features of measuring panel HDCM-8500” Standard Features : Digital display for unbalance indication Amount and angle for unbalance for both planes displayed on separate DPMs. Hence linear accuracy is very goos as compared to analog meter +digit for amount and + degree for angle. Digital display for RPM indication A DPM is provided to indicate balancing speed continuously as a standard feature. Auto Stop No necessity to stop machine once started. It stops automatically after stabilization of unbalance results. Simultaneous Indication Amount and angle of unbalance in both planes displayed simultaneously and remains displayed (stored ) till next run. This totally eliminates operation of plane selector and reduces additional time for stabilization of readings in other plane. Key-Board Data of rotor dimensions and balancing tolerance i.e. values of A, B, C, R1, R2, t11, t12 are fed by key operation. Hence accuracy of data feedings accurate up to 1 digit. Tolerance Indicators Separate LEDs are provided for both planes which glow when unbalance is reduced within balancing tolerance. Auto Range Depending upon whether unbalance amount is more or less a respective course or fine range gets automatically selected till rotor gets balanced within tolerance limits, Multiplier operation is totally eliminated. Data store Data is provided with 'Self check' mode which checks proper functioning of digital display. LED's is cycle operation. This helps immediate fault detection. Self Check Panel is provided with ‘self-check’ mode which checks proper functioning of digital displays, LEDs is cyclic operation (optional). This helps immediate fault detection. Additional Featureson demand : Printer : A matrix printer can be connected through ‘FIE’ software. It shows runs till rotor is balanced within balancing tolerance. Component Indication : ‘FIE’ software specially developed with 3-99 component indication, is suitable for balancing of rotor with fixed locations for balancing correction. Unbalance Correction : Drill attachment 8mm capacity portable drill with supporting overhead railing. Separate drilling attachment 19mm. Capacity with a vertical drilling head , manual. Portable type reveting hammer (piston type) speed 1800 blows/minute, capacity 6mm in a aluminum suspected from top with rail. Tangential belt drive, in addition to standard (suitable for a particular type of rotor for production balancing) Longitudinal movement of right hand pedestal by chain & sprocket attachment. • The balancing speed depends upon selection of the rotor diameter, where drive is to be given and the motor pulley diameter. • All the machines above operate on mains supply of 400 to 440 V, 3Ø, 50 cycles. • Due to constant R & D, specifications and features are subject to change without notice. The dimensions given above are approximate.

...more

Dry Belt Grinders

Various types of dry belt grinders Belt width up to 200 mm Also available with dust collector Dust collector open & enclosed types.

...more

Double Disc Polishing Machine

Table top single disc polishing machine Variable speed from 150 to 1200 rpm. For grinding & polishing microscopic inspection of metals, ceramics.

...more

Data Logger with Printer Interface

• It is a low cost solution for getting print outs for characteristics & graphs for components like Shock Absorbers, Brake Lining, Clutches etc. • Nicety of the product is it never demand PC printer interfacing.

...more

Computerized Brinell Hardness Tester

We are the leading manufacturers, exporters and supplier of this products.

Brand Name : FIE

Material : Metal

...more

computerised vickers hardness tester

Fully Computerised (PC Based) Vickers Hardness Machine. Direct and accurate measurement of Vickers Hardness number using "State of the Art" image processing technology. Wide testing range : from soft metal up to hardest. High accuracy and repeatability of measurement at all loads. Faster measurement yielding to higher productivity. Small size of indentation makes it a non destructive testing on finished components. Motorised loading and unloading cycle. Small loads allow testing of thin sheet metals. Advanced Window XP based software : Latest GUI Features : • User friendly software with Windows Features. • Online indentation setting and focusing on PC monitor. • Advance image processing : Algorithms implemented for precise calculation of hardness numbers with various options to cover all ranges of specimen. Batch file Processing : Option for Data, storage and reports generation. Statistical Evaluation : Software forcalculating standard deviation, mean, medium, histogram etc. • Wide options in calibration mode.- Calibration / Verification on PC monitor makes easier to operate. Specifications : Computerised Hardness Tester is a simple and accurate means to produce automatically measure the diamond indentation to give Vickers hardness numbers. These testers are suitable for measuring the hardness of precision metallic parts with wide testing range - from soft to hard and their accurate results are widely acclaimed. These testers strictly confirm to IS 1754 - 2002. Construction : The robust machine frame is designed to accommodate the high precision loading. Specimen is placed on a testing table. The test cycle is fully automatic. The accurate load is applied on a diamond indentor by means of a lever and weights. After a specific lapse of a time the load is removed automatically. The image is digitized using a CCD camera fitted on the machine and is captured by PC. The diagonals of the indentation are automatically measured by PC to give the Vickers Hardness Number. PC requirements : • Intel Pentium IV 2.00 GHz or above processor is recommended. • Microsoft Windows 98SE or above (Recommended XP) • System Ram : 128 MB or above (Recommended 256 MB) • One RS 232 (serial) port. (PC not included in standard scope of supply)

...more

Dynamic Balancing Machine

Machines Model HDM are horizontal type universal hard bearing balancing machines provided with Microprocessor based measuring panel HDM-8500 for balancing different shapes of rotors like rotors of electrical machines, crankshafts, cylinders, Gas Compressors, flywheels, turbine rotors, rotors of centrifugal pumps and any other type of rotors of rotating machines. These machines features a very simple operation. The working cycle is fully automatic. From safety point of view a double press push button starts machine, measures and stores the unbalance values on DPMs for two planes simultaneously and stops machine ( with brake if machine is provided with electrical breaking facility.) The measuring cycle general is less than 10 seconds for normal rotors, which can be accelerated within 5 seconds.

...more

Calibration Services

Calibration Services

Material Testing Machines Services is providing calibration services for testing machines like hardness tester & Universal testing machine, Tensile testing machine. Our laboratory is well equipped with instruments having National / International traceability. We are providing calibration services meeting the requirements of ISO / IEC 17025 : 1999, NABL specific criteria & customers' requirements. Our NABL registration number is C - 0262. Final assessment of NABL has satisfactorily completed on 5 th & 6 th April 2004. These calibration services can be undertaken in presence of National / International inspection agencies like IRS, LRIS, TUV, BVQI, ABS, CHEMPRO & govt. inspection agencies like IBR, EIL, NPCIL etc on request. We undertake annual maintenance contract (A.M.C.) for these machines. We ensure no down time of any of the testing equipment under A.M.C.. For that we maintain all necessary spares in our stock. We are also giving services for following machines : • Impact Testing Machine (Charpy & Izod) - As per IS / BS / ASTM • Microvickers Hardness Tester • Metallurgical Microscope • Metallurgical Instruments like Cut-off Machine, Polishing Machine etc.

...moreBe first to Rate

Rate ThisOpening Hours