Tunnel Dryer

Tunnel Dryers are ideal for drying of Granulated / Extruded / Briquettes / Flakes / Fibrous / Pre Formed materials. Few of the applications are Ceramic Fiber Papers, Ceramic Fiber Boards, Molded Paper Products, Rayon Staple, Cotton linters, Noodles, Food products etc. AVM offers Customized Tunnel Drying Systems with variety of Configurations. Operation Configurations : Continuous / Semi-continuous/ Batch. Single Pass / Multi Pass. Single / Multi Temperature & Airflow Controlled Zones. Once through / Re-circulating air modules. Air Flow Patterns Configurations : Parallel Flow. Counter-current Flow. Cross Flow. Combination Flow. Through Circulation. Material Movement Configurations : Continuous on Metallic Mesh Belt Conveyor. Continuous on chain mounted Moving Trays / Pallets. Semi-Continuous on Carts / Trolleys. Batch on Trays / Trolleys / Pallets. Air Heating System Configurations : Direct Fired / Indirect Fired Air Heaters : Using Liquid / Gaseous Fuels. Direct / Indirect Fired Air Heaters : using Solid Fuels, Agro Waste, Saw Dust, Rice Husk, Coal, Briquette etc. Indirect Air Heaters : Using Steam / Hot Oil / Thermic Fluid. Electric Air Heaters: using electricity.

...more

Tube Bundle Dryer

In this Dryer, tube bundle is rotating inside stationary housing. Heating Media is passed through the tubes of Tube Bundle. Material to be dried is fed into the stationary dryer housing at suitable location at one end. The material gets lifted up & showered on tubes with help of specially designed lifters provided on tube bundle periphery. Material gets dried by conduction heat transfer & discharged from the other end. AVM offers customized configurations of Tube Bundle Dryers. Material Flow: Co-current / Counter-current. Vapor Exhaust : Natural Draft / Induced Draft. Fines Recovery : Cyclones / Bag Filters / Settling Chambers. Heating Media : Steam / Hot Oil / Thermic Fluid. Feed preconditioning, Product back-mixing systems. Feed & product handling, conveying systems.

...more

Industrial Spray Dryer

Spray Dryer technology is widely used in the industry for converting liquid solutions/ suspensions/ slurry /emulsions to powder, granules or agglomerates. The advantages of spray drying are consistent product quality, with better control on product parameters like product moisture, bulk density, particle size, dispersion, flow ability etc. AVM offers Customized Spray Drying Systems with variety of Configurations. Air Flow Pattern Configurations : Co- current. Counter-current. Mixed flow. Combination of Systems Configurations : Two Stage Spray Dryer : Spray dryer followed by fluid bed dryer for drying products which require longer residence time & product conditioning post drying. Three Stage Spray Dryer : Spray dryer with Internal fluid bed followed by external fluid bed dryer for producing dust free agglomerates. Liquid Atomizer Configurations : Single Fluid Nozzle Atomizers : The liquid feed is atomized into spray droplets by using pressure energy. Two Fluid Nozzle Atomizers : The liquid feed is atomized into spray droplets by using energy of secondary fluid like Compressed Air, Nitrogen etc. Rotary Disc Atomizers / Rotary Atomizers : In Rotary disc Atomizers, the kinetic energy of wheel is used for atomization. Air Heating System Configurations : Direct Fired / Indirect Fired Air Heaters: using Liquid / Gaseous Fuels. Direct / Indirect Fired Air Heaters: using Solid Fuels, Agro Waste, Saw Dust, Rice Husk, Coal, Briquette etc. Indirect Air Heaters: Using Steam / Hot Oil / Thermic Fluid. Electric Air Heaters: using electricity. Product / Fines Recovery System Configurations : Cyclone Separators – Mono, Twin, Quadruple, Multi etc. Bag Filters – Reverse Pulsejet, Mechanical shaking etc. Wet Scrubbers – Direct Contact Ventury, Adjustable Ventury, Packed scrubbers etc. Optional Features Configurations : Rotating air brooms with dehumidified air. Roof cooling. Rotary atomizer Cooling. Nozzle Lance Cooling. Online Dosing & Blending system. Product Cooling & conveying system. Online gas induction system in feed liquid. Feed Preparation system. Closed Loop Systems / Self Inertized Systems with inert gas as process drying media. Solvent Recovery Systems. Cleaning in Place Systems. Heat Recovery Systems. CGMP Construction. Safety accessories like Explosion vents with pressure shock resistant design for equipments, explosion de-coupling, Mechanical flame diverter, Vacuum breaker, Fire fighting system. Computerized control system through PLC / DCS & SCADA.

...more

Spray Cooler

Spray Cooler Technology is a process to convert Melt into solid state by Spraying into Spray chamber. Cooling media is usually dehumidified cold air. The cooling media is admitted into the Spray Chamber. The spray mist comes in intimate contact with the cooling media & gets converted into solid state.AVM offers Customized Spray Cooling Systems with variety of Configurations.Air Flow Configurations : Co-current. Counter current. Mixed Flow. System Configurations : Single Stage Spray Coolers. Two Stage Spray Coolers. Multi Stage Spray Coolers. Liquid Atomizer Options : Single Fluid Nozzle. Two Fluid Nozzle. Rotary Disc Atomizer. Air Cooling Systems Configurations : Air Dehumidifiers & Coolers - using utility like Chilled Water, Brine etc. Air Dehumidifiers & Coolers - using direct expansion of Refrigerant, Ammonia etc. Fines Recovery Systems Configurations : Cyclone Separators – Mono, Twin, Quadruple etc. Bag Filters – Reverse Pulsejet, Mechanical shaking etc. Optional Feature Configurations : Heat tracing for feed line using hot water / steam / electricity as utility. Nozzle lance pre-heating, Heated secondary media for Two fluid nozzles. Re-circulation of exhaust gas for higher thermal efficiency. Safety accessories like Explosion vents with pressure shock resistant design for equipments, Vacuum breaker. Computerized control system through PLC / DCS & SCADA.

...more

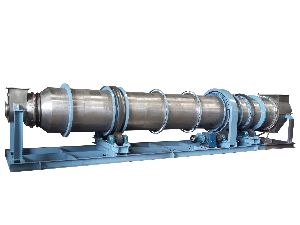

Rotary Steam Tube Dryer

In this dryer, tubes are fixed to the outer shell housing & rotate along with the shell. Single / Multiple rows of tubes are circumferentially arranged on the internal periphery of the rotary shell. Rotary Steam Tube Dryer is supported on tyres / rollers & driven through suitable drive arrangement. Wet feed material is fed through center of one end of the Dryer by feed screw. Steam is admitted in the circumferential tubes from a rotating manifold installed towards material discharge end of the shell through Rotary Joint. Condensate is also collected through the same Rotary Joint. Material gets dried by conduction heat transfer & discharged from the openings provided on the shell at the other end. The openings also serve for fresh air intake. Vapors are removed from the feed end. Spiral flight lifters showered the feed material on tubes. AVM offers customized configurations of Rotary Steam Tube Dryers. Vapor Exhaust : Natural Draft / Induced Draft. Fines Recovery : Cyclones / Bag Filters / Settling Chambers. Heating Media : Steam / Hot Oil / Thermic Fluid. Feed preconditioning, Product back-mixing systems. Feed & product handling, conveying systems.

...more

Rotary Dryer

Rotary Dryers / Coolers are widely used in the Industry for drying / cooling of reasonably free flowing materials. AVM offers Customized Rotary Drying Systems with variety of Configurations. DIRECT ROTARY DRYERS & COOLER The material to be dried / cooled comes in direct contact with the drying / cooling media. The dryer comprises of a rotating shell supported on rollers / tyres and driven by means of suitable drive arrangement. Drying / Cooling media (Air / Gas) is admitted through stationary hood at one end & taken out from stationary hood from other end. Feed is admitted through suitable feeding mechanism like Screw feeder / Chute. The rotating shell is provided with specially designed material showering mechanism like Lifters / Garland Chains etc. Shell inclination & rotating speed facilitate forward movement of the material towards discharge end providing required residence time. Drying (or Cooling) takes place by heat transfer to (or from) showering material with the drying (or Cooling) media within the shell. Product is discharged from the stationary hood through suitable equipment like Flap Valve / Rotary Valve / Screw Conveyor / Chute. Air Flow Configurations : Co-Current Flow Counter-Current Flow Air Heating System Configurations : Direct Fired / Indirect Fired Air Heaters: using Liquid / Gaseous Fuels. Direct / Indirect Fired Air Heaters: using Solid Fuels, Agro Waste, Saw Dust, Rice Husk, Coal, Briquette etc. Indirect Air Heaters: Using Steam / Hot Oil / Thermic Fluid. Electric Air Heaters: using electricity. Product / Fines Recovery System Configurations : Cyclone Separators: Mono, Twin, Quadruple, Multi etc. Bag Filters: Reverse Pulsejet, Mechanical shaking etc. Wet Scrubbers – Direct Contact Ventury, Adjustable Ventury, Packed scrubbers etc. Optional Features Configurations : Feed material conditioning. Back mixing of product with feed material. Pneumatic conveying system and finish product handling. Computerized control system through PLC / DCS & SCADA. IN-DIRECT ROTARY DRYERS The material to be dried does not come in direct contact with the drying media. The dryer comprises of an assembly of two concentric rotating shells supported on rollers / tyres and driven by means of suitable drive arrangement. Feed is admitted through suitable feeding mechanism like Screw feeder / Flap Valve into the dryer through stationary feed hood. The drying media is admitted through the inner shell & travel towards discharge end & again returns towards feed end through specially designed return gas passages on the inside of outer shell. The inner shell is also provided with suitable radial lifters. These lifters along with return passages geometry is designed for showering of feed material. Shell inclination & rotating speed facilitate forward movement of the material towards discharge end providing required residence time. Drying takes place by heat transfer to the showering material by direct contact with inner shell & return passages. Product is discharged from the stationary hood through suitable equipment. Air Heating System Configurations Direct Fired Air Heaters : Using Liquid / Gaseous Fuels. Direct Fired Air Heaters : Using Solid Fuels, Agro Waste, Saw Dust, Rice Husk, Coal, Briquette etc. Product / Fines Recovery System Configurations : Cyclone Separators: Mono, Twin, Quadruple, Multi etc. Bag Filters: Reverse Pulsejet, Mechanical shaking etc. Wet Scrubbers – Direct Contact Ventury, Adjustable Ventury, Packed scrubbers etc. Optional Features Configurations : Feed material conditioning. Back-mixing of product with feed material. Pneumatic conveying system and finish product handling. Computerized control system through PLC / DCS & SCADA.

...more

Rotary Calciner

Rotary Calciners are used for calcining of the material at high temperature. The Rotary Calciner comprises of rotating shell supported on rollers / tyres and driven by means of suitable drive arrangement. The internals are suitably refractory lined to minimize the heat losses. The combustion chamber is used for producing hot gases required for the calcination and it is connected to the Rotary Calciner through a stationary hood. The feed material is fed into the calciner feed hood through Screw Conveyor at controlled rate. The materials to be calcined travel in counter current fashion within the Calciner and gets discharge through discharge hood. Air Heating System Configurations : Direct Fired / Indirect Fired Air Heaters: using Liquid / Gaseous Fuels. Direct / Indirect Fired Air Heaters: using Solid Fuels, Agro Waste, Saw Dust, Rice Husk, Coal, Briquette etc. Fines Recovery Options : Cyclone Separators – Mono, Twin, Quadruple etc. Bag Filters – Reverse Pulsejet, Mechanical shaking etc. Optional Features : Pulverizing of Feed / Product Feed Material Pre-Heating Arrangement. Rotary Cooler for cooling of calcined product. Pneumatic conveying systems for feed material and finish product handling. Computerized control system through PLC / DCS & SCADA.

Type : Automatic

Material : Stainless Steel

Application : Industrial Use

Finishing : Polished

Power : 0-5Kw

Warranty : 1 Year

Orientation : Vertical

After-Sales Service Provided : Spare Parts

...more

Rotary Atomizers

Rotary Atomizers are used in Spray Drying for atomizing the feed into fine droplets. In Rotary Atomizers, the kinetic energy of wheel rotation is used for atomization of the liquid. Droplet size of atomized liquid depends upon liquid properties, disc speed, disc configuration etc. Bulk density is also one of the critical product requirement of spray dried products. The desired results can be achieved by using different Atomizer wheel configurations and optimizing atomizer speed, optimizing relevant feed properties

...more

Pneumatic Conveying Machine

Pilot Spray Dryer

‘AVM’ Pilot / Mini Spray Dryer is an excellent choice for Laboratory testing, Small-scale powder production requirements.These plants are designed for an evaporation capacity ranging from 3 kg/hr to 60 kg/hr.‘AVM’ Pilot Spray Dryers are complete skid mounted packaged plants, comprising of Air heating section, Spray chamber, Cyclone separator, Bag filter liquid pumping system, liquid atomization system, air circulation blowers, Control Panel with Instruments.AVM offers Pilot / Mini Spray Dryers with variety of Configurations.Air Heating System Configurations : Direct Fired / Indirect Fired Air Heaters: using Liquid / Gaseous Fuels. Indirect Air Heaters: Using Steam / Hot Oil / Thermic Fluid. Electric Air Heaters: using electricity. Feed Liquid Atomization Options : Rotary Disc Atomizers Two Fluid nozzles High Pressure Nozzles Additional Features Configuration : 2 Stage Systems with Internal Fluidized Bed. Closed Loop Systems with inert gas as process drying media. Solvent Recovery System. Rotating air Brooms for sweeping chamber walls. Air Cooled Jacketed Chamber. Pre-dehumidification of Drying Air. Special Materials of Construction. CGMP construction. Computerized control system through PLC / DCS & SCADA.

...more

Paddle Blender

AVM offers customized Allied Equipments / Systems with variety of Configurations. Blenders / Powder Mixers Equipments configured for Batch or Continuous Operation. Capacities as per system requirements. Paddle Type Blenders. Ribbon Type Blenders. Special Rotor Type Blendors. Double Cone Blenders. Double Shaft Paddle Mixers. Online Product Blenders with controlled liquid dosing as per system requirements. Liquid Feed / Slurry Preparation Systems Agitated Reaction Vessels. Vessels with Heating, cooling, sparging mechanism. High Speed Blungers. Material Handling Systems Double Flap Valves: Motorised / Counterweight type. Rotary Air Lock Valves : Drop Through / Blow Through type. Rotary Feeders. Screw Conveyors. Pneumatic Conveying Systems: Lean Phase Suction Type. Pneumatic Conveying Systems: Lean Phase Positive Pressure Type. Cleaning In Place (CIP) Systems Single Tank System / Three Tank System. Motorised Winch system for large vessels cleaning. Wall flush nozzles for cleaning od ductings, equipments. Fully automated systems with PLC / DCS & SCADA.

...more

Fluid Bed Dryer

Fluid Bed Dryer / Cooler are widely used in the Industry for gentle drying / cooling of free flowing solids. In fluid bed systems, the material is fluidized with help of air stream using specially designed perforated plate. In addition to this, the fluidizer can also be made vibratory to assist the fluidization by imparting mechanical energy. Drying / Cooling media (Air / Gas) is admitted in the plenum below the perforated plate. Fluidized state enables intensive interaction & of the material & drying / cooling media (air / gas) takes place; hence high rates of heat transfer are achieved. Product residence time can be adjusted through adjustable discharge weir. Product Drying and cooling is possible in single unit. AVM offers Customized Fluid Bed Drying Systems with variety of Configurations. Continuous Fluid Bed Configurations : Static Fluid Bed Dryers. Vibratory Fluid Bed Dryers. Material Feeding Options : Rotary Feeder. Screw Feeder. Product / Fines Recovery System Configurations : Cyclone Separators – Mono, Twin, Quadruple Cyclones etc. Bag Filters – Reverse Pulsejet, Mechanical Shaking etc. Air Heating System Configurations : Direct Fired / Indirect Fired Air Heaters : Using Liquid / Gaseous Fuels. Direct / Indirect Fired Air Heaters : Using Solid Fuels, Agro Waste, Saw Dust, Rice Husk, Coal, Briquette etc. Indirect Air Heaters : Using Steam / Hot Oil / Thermic Fluid. Electric Air Heaters : Using electricity. Optional Features Configurations : Automatic CIP system. Liquid Spraying System for Product having requirement of Coating / Lecethination. Safety accessories like Rupture Disc, Fire Fighting System. Computerized Control System through PLC/ DCS / SCADA.

...more

Flash Dryer

In Flash Dryer, the wet feed is dispersed into the hot air / gas stream in the drying duct through suitable feed dispersing mechanism. The material gets dried during conveying travel through the drying duct & separated in the Cyclones or bag filters. Some applications require pre-conditioning of feed by back-mixing of dry product or mixing with oversize particles tapped through particle classifiers installed at suitable locations on the drying duct. AVM offers Customized Flash Drying Systems with variety of Configurations. Material Feeding Configurations : Mono Screw Feeder. Double Screw Feeder Double Paddle Mixer for back mixing of dry product Feed Bin with Lump Breaker. Volumetric feeder Rotary Feeder. Feed Disperser Configurations : Sling Fan. Cage Mill. Mechanical Scatterer. Chain Slinger. Ventury Feeder. Combinations of above. Oversize Particle Classifier Configurations : Deflector Hood. Ring Classifier. Air Heating System Configurations : Direct Fired / Indirect Fired Air Heaters : Using Liquid / Gaseous Fuels. Direct / Indirect Fired Air Heaters : Using Solid Fuels, Agro Waste, Saw Dust, Rice Husk, Coal, Briquette etc. Indirect Air Heaters : Using Steam / Hot Oil / Thermic Fluid. Electric Air Heaters : Using electricity. Product / Fines Recovery System Configurations : Cyclone Separators – Mono, Twin, Quadruple, Multi etc. Bag Filters – Reverse Pulsejet, Mechanical shaking etc. Wet Scrubbers – Direct Contact Ventury, Adjustable Ventury, Packed scrubbers etc. Optional Features Configurations : Product Cooling and Conveying Systems. Exhaust gases Recycling for better thermal efficiencies. Safety accessories like Static Jumpers, Fire Fighting Systems, Rupture Disc etc. Computerized control system through PLC / DCS & SCADA.

...more

Fines Recovery System

EXHAUST EMISSION / POLLUTION CONTROL / FINES RECOVERY SYSTEMS AVM offers customized Systems exhaust emission / pollution control / fines recovery systems with variety of Configurations. Bag Filters & Dust Collection Systems : AVM offers Reverse Pulse Jet type Bag Filters for Industrial applications in several customized configurations. Pulsing Configurations : On-Line Pulsing, Modular Off-Line Pulsing. Flow Rates : As per system requirement. Operating Temperature Range : Up to 260°C. Housing Type : Cylindrical Housing, Rectangular Housing. Air Entry Configurations: Hopper entry with side / central distribution, Tangential entry. Plenum Configurations: Top Access, Walk through etc. Electrical heat tracing for bottom hopper. Cleaning In Place system ( CIP) for special applications. Safety Accessories like Fire fighting system, Explosion vents, Antistatic construction etc. Air Ingress system for filter bags protection against temperature surges. Bag filters with Mechanical shaking arrangement can also be offered. Cyclone Separators : Mono, Twin, Quadruple, Multiple Cyclones depending on system requirement. Tangential, Wrap Around Inlet configurations. Distributed Inlet & Outlet configurations for Multiple Cyclones. Wet Scrubbing Systems : Direct Contact Spray Type Ventury Scrubbers. Droplet Separators. Adjustable area ventury type with manual / automated adjustment. Scrubbers with tower packing, saddle packing, demister mesh packing.

...more

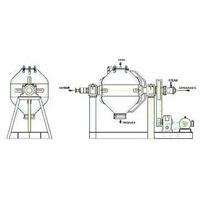

Double Cone Vacuum Dryer

In Double Cone Vacuum Dryer, heat is supplied to double conical shaped rotating jacket. The material to be dried is kept in continuous tumbling within the rotating housing. Conical shape facilitates easy drain out of material at the end of the batch. Features Configurations Heating Media: Steam, Hot Water/Oil, Thermic Fluid. Side Mounted Choppers. Solvent Recovery.

...more

auxiliary machine

AVM offers wide range of customized Systems with variety of Configurations.

...more

Air Heater

AIR HEATERS / GAS HEATERS / HOT AIR GENERATOR SYSTEMS AVM offers wide range of customized Heating Systems with variety of Configurations. Types of Indirect Heated Air / Gas Heating Systems Offered : Multiple Concentric Shells Type. Shell & Tube Type. Multi - Coils in Shell Type. External Recuperator Type. Tube Bundle over Combustor Bed. Finned Tube Type Air Heater. Types of Direct Fired Air / Gas Heating Systems Offered : Single Shell Combustion Chamber. F.B. Combustor. Multiple Concentric Shell all metal construction (Without Refractory Lining). Concentric Shell Type With Refractory Lining. Duct Mounted. Operating Capacities of Heating Systems : Air Flow Rates up to 150,000 Nm^3/hr. Higher flow rates can also be offered. Heated Air Temperatures up to 690 °C for Indirect Type. Heated Air Temperatures up to 1500 °C for Direct Fired Type. Types of Fuels / Heating Media for Heating Systems : Liquid Fuels: HSD, Light Oil, Heavy Oil, SKO etc. Gaseous Fuels: LNG, CNG, Propone, LPG, Producer Gas, Bio Gas etc. Solid Fuels: Bio-waste, Saw Dust, Wood Chips, Coal, Rice Husk, Briquettes etc. Heating Media: Steam, Hot Oil, Thermic Fluid, Electricity etc.

...more

Agitated Vessel

AVM offers customized Allied Equipments / Systems with variety of Configurations. Blenders / Powder Mixers Equipments configured for Batch or Continuous Operation. Capacities as per system requirements. Paddle Type Blenders. Ribbon Type Blenders. Special Rotor Type Blendors. Double Cone Blenders. Double Shaft Paddle Mixers. Online Product Blenders with controlled liquid dosing as per system requirements. Liquid Feed / Slurry Preparation Systems Agitated Reaction Vessels. Vessels with Heating, cooling, sparging mechanism. High Speed Blungers. Material Handling Systems Double Flap Valves: Motorised / Counterweight type. Rotary Air Lock Valves : Drop Through / Blow Through type. Rotary Feeders. Screw Conveyors. Pneumatic Conveying Systems: Lean Phase Suction Type. Pneumatic Conveying Systems: Lean Phase Positive Pressure Type. Cleaning In Place (CIP) Systems Single Tank System / Three Tank System. Motorised Winch system for large vessels cleaning. Wall flush nozzles for cleaning od ductings, equipments. Fully automated systems with PLC / DCS & SCADA.

...more

Agitated Swirl Flash Dryer

In Agitated Swirl Flash Dryers, the wet feed is fed into the dryer housing by suitable feeding mechanism above the rotating swirl agitator. The hot air / gas stream is also admitted in the drying duct through specially designed distributor, admitting the air in swirling fashion. The material remains in agitated bed & dried material gets carried forward & separated in the Cyclones or bag filters. Some applications require pre-conditioning of feed by back-mixing of dry product.AVM offers Customized Agitated Swirl Flash Drying Systems with variety of Configurations.Material Feeding Configurations : Mono Screw Feeder Double Screw Feeder Double Paddle Mixer for back mixing of dry product Feed Bin with Lump Breaker Volumetric feeder Rotary Feeder Specially design double shaft feeder followed by mono screw. Positive Displacement Screw Pump for Viscous liquid / Pastes. Particle Classifier Options : Orifice Classifier Rotary particle Classifier Air Heating System Configurations : Direct Fired / Indirect Fired Air Heaters: using Liquid / Gaseous Fuels. Direct / Indirect Fired Air Heaters: using Solid Fuels, Agro Waste, Saw Dust, Rice Husk, Coal, Briquette etc. Indirect Air Heaters: Using Steam / Hot Oil / Thermic Fluid. Electric Air Heaters: using electricity. Product / Fines Recovery System Configurations : Cyclone Separators – Mono, Twin, Quadruple, Multi etc. Bag Filters – Reverse Pulsejet, Mechanical shaking etc. Wet Scrubbers – Direct Contact Ventury, Adjustable Ventury, Packed scrubbers etc. Optional Features Configurations : Product Cooling and Conveying Systems. Exhaust gases Recycling for better thermal efficiencies. Safety accessories like Static Jumpers, Fire Fighting Systems, Rupture Disc etc. Water Cooled Dryer Agitator bearing housing for high temp. operation. Computerized control system through PLC / DCS & SCADA.

...more

Agitated Cylindrical Vacuum Dryer

In these dryers, heat is supplied to jacket of stationary cylindrical housing. The material to be dried is kept in agitation by means of specially designed rotor. Features Configurations : Rotor Types: Helical Ribbon, Paddles, and Special. Heating Surfaces: Shell, End Covers, and Shaft. Heating Media: Steam, Hot Water/Oil, Thermic Fluid. Side Mounted Choppers. Solvent Recovery.

...moreOpening Hours