Ball Valve

80 - 250 Per Piece

50 Piece (MOQ)

Ball Valve

Get Price Quote

20 Piece (MOQ)

Best Deals from Nova Valves

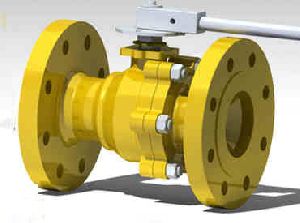

Ball Valves

3,500 - 36,000 Per Piece

Ball Valve

Get Price Quote

Application : Petroleum, Petrochemical Chemical, Refrigeration, air-conditioning and engineering industries. Valves are compatible with Ammonia, CFC, HCFC, Oil, Air, Chemicals, Gas, Acids, Alkalies etc. amongst many other media. Installation : The three piece design makes the Series C-44 valve the most easily maintainable valve in its type. By removing three body connector bolts and loosening the fourth, the body can be swung away using the fourth bolt as a fulcrum, to carry out any maintenance on the valve. This feature allows the valve to be online and considerably reduces down time. Safe Working Pressure : 40 Bar. Temperature : -40/+125°C

Ball Valve

Get Price Quote

With the Series 819 / 829 designed to BS EN ISO 17292 / API 6D, AUDCO brings to the market a full bore valve which combines low cost of ownership and long service life with high operational safety and a range of features which sets the standards for others to follow.

Ball Valve

Get Price Quote

Unique AIVA design - life long service, Ball Pressure adjusting feature. Manufactured from pigmented UPVC resistant virgin polymer and other material such as delrin and silicon rubber - suitable for potable water. Due to its modular design it is very easy to service the ball valve if required. Compression outlet make it easy & quick to install.

Ball Valve

Get Price Quote

10 Piece (MOQ)

Cast Iron Valves

Get Price Quote

We are offering cast iron valves. Available with us a wide range of ISI marked Cast Iron Valves that is widely demanded amidst the customers. Our range of Cast Iron Valves is perfect to be used in varied applications like those of water, sewage and neutral liquid, etc. Variety : Cast iron sluice valveGlobe valveNon return valveBall type nrvFoot valvesKnife edge gate valve Technical Specifications : Sizes available :From 1” to 24” ( 25 mm to 600 mm) Material used :Cast IronRating (Class ) :PN 1.0,1.6End Connections :Flanged endsDrilling :As per BS 10 T-D, E, F As per customer specificationOperations :Hand wheel OperatedGear OperatedElectric Actuator

Ball Valves

Get Price Quote

Ball Valve

Get Price Quote

Introduction:- The ball valve stands as one of the foundational elements within industrial setups. But what sets this valve apart from the rest? Let’s explore its inner workings, varied applications, and numerous advantages to understand its significance in industrial operations Ball Valves Understanding the Ball Valve: A ball valve operates with a simple quarter turn of a handle, allowing fluid to flow or stopping it in its tracks. It’s a type of rotary valve, meaning it operates by rotating a quarter turn (45 or 90 degrees) to control the flow of fluids. The magic happens thanks to a ball-shaped disc inside the valve, which gives it its name. This ball, when aligned with the flow inlet, allows fluid to pass through, and when rotated 90 degrees by the valve handle, it shuts off the flow completely. Types of Ball Valves: Ball valves come in various forms, including single-body and three-piece configurations, depending on how they’re manufactured and assembled. However, their operation remains consistent across the board as rotary valves. Applications of Ball Valves: The versatility of ball valves makes them indispensable in numerous industries. They’re the go-to choice for shutdown operations in refineries and fertilizers, thanks to their quick on-off action. Additionally, they’re ideal for applications requiring low pressure, as they perform optimally when fully open, reducing pressure effectively. Ball valves also find their place as control valves, offering a variety of uni, bi, and multi-directional options to suit diverse needs. Advantages of Ball Valves: What sets ball valves apart from the competition? Here are some compelling advantages: Durability: Ball valves are built to last. Even if left unused for extended periods, they maintain their performance, making them a reliable choice for long-term use. Quick On/Off: Need to shut down the flow swiftly? Ball valves excel in rapid on-off applications, ensuring efficient operation when time is of the essence. Leakage Prevention: With their tight seal when closed, ball valves minimize the risk of leakage, offering peace of mind in critical operations. Compact and Lightweight: In comparison to other valve types, ball valves boast a smaller size and lighter weight, making them not only easier to handle but also more cost-effective in terms of installation and maintenance. Multiport Design: For applications requiring complex flow control, ball valves with multiport designs are available, providing flexibility and efficiency in managing fluid flow. Conclusion:- In conclusion, ball valves may appear simple at first glance, but their impact in industrial settings is profound. From their effortless operation to their wide-ranging applications and undeniable advantages, it’s clear why they’re a preferred choice for engineers and operators alike. Whether it’s managing flow in a refinery or controlling processes in a manufacturing plant, the humble ball valve continues to play a pivotal role in keeping operations running smoothly.

Ball Valve

130 Per Piece

10 Piece (MOQ)

Ball Valve

Get Price Quote

A ball valve is a quarter-turn rotational motion valve that uses a ball-shaped disk to stop or start flow. If the valve is opened, the ball rotates to a point where the hole through the ball is in line with the valve body inlet and outlet. If the valve is closed, the ball is rotated so that the hole is perpendicular to the flow openings of the valve body and the flow is stopped.

Ball Valves

Get Price Quote

Ball Valve

Get Price Quote

Our Manufacturing & Supply Scope Body Stem Ball

Ball Valves

Get Price Quote

PARTH VALVES AND HOSES LLP is pleased to offer top-of-the-line products in pipeline flow control. The PARTH VALVE AND HOSES ‘s Ball Valves have been developed with extensive application, design and manufacturing expertise. These products are produced by employing modern manufacturing practices under a robust quality assurance system. These practices ensure consistent product quality and dependable performance. The PARTH VALVE AND HOSES ‘s Ball Valves have been designed to include state-of-the-art features that are described in this bulletin. TECHNICAL DATA PARTH VALVES AND HOSES has extensive experience in manufacturing floating ball valve as well as Trunnion Mounted Ball Valves, Full bore ball valve, Reduced bore ball valve, both Soft and Metal Seated. Size: 1/2” up to 12“(DN 15 up to DN 300) Pressure Rating: ASME 150# to 300# Materials: Carbon Steel, stainless Steel (SS304, SS316, SS316L) Duplex Stainless Steel, Super Duplex Stainless Steel, Alloys. Design Standard: design generally conforms to ASME B 16.34-2004 / API6D / BSEN ISO 17292 (BS5351); DIN EN 12516 Also, IS9890-1981 Temperature Rating: -10 degree to 230 degree. Test (Inspection) Standard: IS 6157-1981, BS 6755 Part 1/API 598 Construction Details: Single / Two / Three Piece Design / Side Entry / Trunnion / Full Bore/Reduced bore/ Block & Bleed / Soft and Metal Seated End Connection: Screwed, Socket Weld, Flanged, Butt-Weld, Triclover End, SMS/DIN union End. Operator / Actuator: Lever, Gear, Actuator (Pneumatic, and Electric Motorized) Special Service almost all PARTH VALVES AND HOSES can designs in a special version as per customer’s Requirements. In this case, all the material details and technical features are given by the Customer & all Design aspects from us. We are Manufacturer, Exporter, Supplier, Authorized Dealer & Solution Provider. Our setup is situated in Pune, Maharashtra, India & majorly we serve our customers from countries like Shri Lanka, Bhutan, Bangladesh, Malaysia, Indonesian, Nepal, Europe, Africa, Gulf countries like UAE, Dubai, Bahrain, Oman, Qatar, Saudi Arabia, Egypt, Jordan, Lebanon, Syria, Yemen, Kuwait etc.

Ball Valves

Get Price Quote

We supply Ball Valves that comply with the API, ANSI, DIN, JIS, BS, GOST, and GB design standards. The port size of our ball valves ranges from 1/2" to 56" and these are made with the casting material. These valves are ideal for media with medium pressure and temperature.

Floating Ball Valves

Get Price Quote

Our floating ball design features a generous corrosion allowance and innovative stem sealing. The products modular design also enables us to manufacture floating ball valves according to project specifications on a fast track delivery. Benefits Our floating ball valve is designed for excellent sealing performance and longevity. We are able to manufacture floating ball valves to complex project specifications on a fast track basis due to our smart sealing design. Our offshore experience also enables us to offer weight saving design options. We manufacture valves in materials ranging from standard Carbon Steel through to exotic alloys such as Super Austenitic st. steel & Inconel. We have developed an extensive supply history in the manufacture of valves in duplex and super duplex st. steel. Design & Manufacturing Standards Our ball valves meet the following standards: API 6D, API 608, BS EN ISO 17292, EN 12516-1,2, ASME B 16.34, ASME B 16.5, 16.10, API 607/ ISO 10497. ✱ Body Sealing Design Our body seals feature O ring plus graphite as standard rather than O ring or graphite only. ✱ Body Sealing Design Our body seal design is modular. We are able to therefore meet our customers body sealing specifications including lip seals and other sealing options. ✱ Stem Sealing Design Our stem design incorporates a tamper proof antistatic device, reduces the friction on the sealing area due to static seal feature. This improves performance and provides a long cycle life as demonstrated by our Fugitive Emissions Testing. The stem design also features live loaded packing and is blowout proof. Variety of stem sealing options viz. O ring, Lip seals, V packing, Cop cone seals etc are available as per customer specifications can be offered in standard design of the valve. ✱ Engineered Seats Compensate for wear and pressures to prolong sealing life. ✱ Shell Design Our design is built to be suitable as standard for most customer specifications in terms of Shell thickness ,corrosion allowance & bolting design requirements. ✱ Actuation Ready Design Our ISO top mounting design reduces the time and cost of actuation. Uniform torques provide prolonged cyclic life. ✱ Devices Standard on lever and gear operated valves ✱ Testing We test to API 598/EN 12266-1, ISO 5208. Fugitive Emission Testing to ISO-15848-1,2. Fire safe to API 607/EN ISO 10497/ API 6Fa.

Ball Valves

Get Price Quote

We are actively involved in the production and distribution of Ball Valves in Maharashtra. The Ball Valves, we provide, are in great demand in several industries due to the precise make and excellent features. We provide a wide variety in Ball valves, which includes SS & Brass Valves. Two Way ball valve Quarter turn can handle pressure upto 3000psi.one piece assembly with simple andCompact design providing positive shut-off to forward flow.Easy to clean and maintain Three Way Ball Valve One piece or two-piece assembly according to pressure requirements316 stainless steel body with robust design and easy switching between pathEasy to clean and maintain Additional Information Minimum Order Quantity : 50Packaging Details : Packaging & Forwarding will charge Extra.Delivery Time : 1 week

Ball Valves

Get Price Quote

We manufacture a wide assortment of ball valves that come in flanged end make that have gained recognition in the market for their excellent features such as compact design and durability. Our entire range of ball valves is available in industry leading price.

Ball Valve

Get Price Quote

We manufacture and export sturdy range of Ball Valve , for various industrial applications. We offer these ball valves in various construction and specifications. Each ball valve, manufactured by us, is thoroughly tested on b5—5146 standards. We can cater bulk requirements of ball valves. We offer mainly single and three piece ball valves. technical specifications

Flanged Ball Valve

Get Price Quote

Design Standard : IS 9890-1981/ENISO17292/API6DTesting Standard of Valves : BS 6755 Part I/API 598/IS 6157-1981 & API607Flange Dimensions : ASME B 16.5 - 2009Face to Face : ANSI B 16.10/API6D

Ball Valves

Get Price Quote

We are offering Ball Valves. Gemini valve is a manufacturer of exceptionally reliable automated, manual and customized valves. Our solutions team professionals specialize in matching the best valves solution for your application from our proven line of compact, reliable ball valves. If your application requires special considerations, gemini's engineered product and design capabilities combined with diversity in manufacturing allows for practical, value oriented customized solutions.

Ball Valves

Get Price Quote

Engineering Options: S.S. 304/316 Parts can be supplied Glass-filled PP/PTFE BALL on request Available M.O.C.: PP (POLYPROPYLENE) HDPE (HIGH DENSITY POLYETHYLENE) ISOTACTIC PP PVDF (POLYVINYLIDENE FLUORIDE)

Ball Valve

1,200 Per Piece

Ball Valves

Get Price Quote

We manufacture of ptfe tube , pfa tube , silicon tube , santoprene tube use for laboratory use , chemical use , analytical use .

Three Way Ball Valves

Get Price Quote

The SANKEY Series 1530L&T- is a versatile large size multi-port ball valve. It can be configured as a three-way valve with "L" or "T" ports. It consists of a heavy-duty centre section with bolted-on flanged ends for Class 150 flanges, Class 300 Flanges. All body gaskets are Teflon. The valve features four seats for equal seat loading, and ball to prevent excessive seat loading and reduce side loading on the stem. It also features a unique live-loaded cup-and-cone lower stem sealthrust bearing that separates the bearing and sealing functions, as well as a multiple upper stem seal.

Ball Valve

Get Price Quote

Ball Valve

300 Per Piece

5 Piece(s) (MOQ)

Ball Valve

1,135 Per Piece

Ball Valve

125 Per Piece

5 Piece(s) (MOQ)