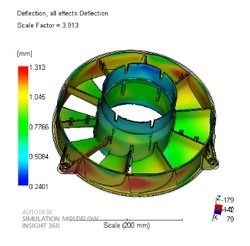

Warpage Analysis Services

To meet the needs of precious consumers, our firm is offering the best part warpage analysis services. This analysis service is much satisfying and accessible from us as per the specific need of work. We finish the analysis service in minimal time. Warpage analysis process: evaluate final part shape before machining the mold evaluate both single cavities as well multi-cavity molds scale shrinkage and warpage results for better visualization of deformation constrain the part on a plane for better measurement of deflection separate total displacement into x-, y-, and z-axis displacements to show only the deflection in each direction

...more

optimization services

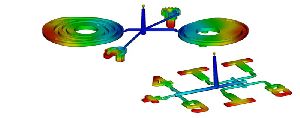

Moldflow Gate Location Analysis Services

With the team of diligent professionals, we are able to provide best gate location analysis services. This analysis service is reliable and appreciated by precious consumers due to the proper accomplishment of work in a simple way. The benefit of moldflow simulation efficient process conditions optimum cooling for cycle time savings optimum gate position for minimum machine size position weld line where you want them runner balancing for minimum scrap eliminate gas traps, sink marks & burning minimize clamp force requirements control fiber orientation even part shrinkage gas injection simulation reduced warpage at fast cycles

...more

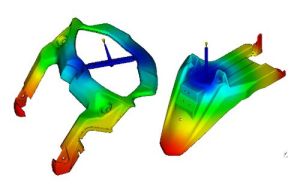

Mold Flow Analysis Services

A mold packing analysis services can be used to optimize the second stage of the injection molding process to achieve the right balance between part quality, part cost, and cycle time. Users can set up and evaluate packing profiles to determine the optimal packing pressure and duration of packing. From the analysis, the user can review the volumetric shrinkage, cycle time, and the average temperature across the part.

...more

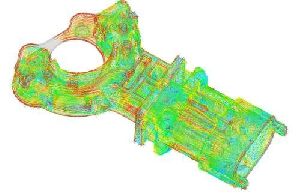

Meshing Services

Fusion mesh, mid-plane mesh and 3d tetrahedral mesh we have extensive experience with all moldflow mesh types and able to supply other moldflow users with a high-quality accurate mesh ready to run. We convert the most complex cad geometries into sophisticated fea models for moldflow analysis simulation.

...more

Fiber Orientation Analysis Services

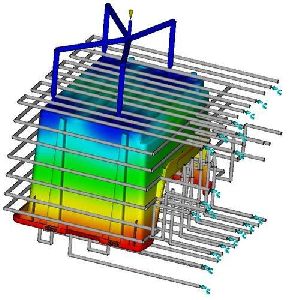

Cooling Analysis Services

The cooling analysis is used to evaluate and optimize cooling line design. Analyzing the cooling phase can help determine the coolant conditions needed to maximize the efficiency of the proposed cooling layout. A cooling analysis can assist in:1. Cycle time optimization2. Effect on warpage3. Evaluation of baffles4. Pressure drop along each cooling circuit.5. Variation in coolant temperature.6.Cavity surface temperature distribution

...moreBe first to Rate

Rate ThisOpening Hours