Tray Dryer Oven

Get Price Quote

10 Piece (MOQ)

Paint Curing Oven

Get Price Quote

1 Piece (MOQ)

Bullows is engaged in manufacturing & suppling of Paint Curing oven ssince its inception in 1963 in all Three types of Curing Ovens; I.e, Electric fired Oven, Gas fired Oven and Diesel fire Oven. Bullows covers paint curing ovens from metal bodies to plastic bodies ,small handles to large engines. Bullows is also specialized in manufacturing of Conveyorised paint dying ovens where the constant temperature has to match with the speed of conveyor vs time.Paint Drying Ovens, also referred to as Dryers or Paint Curing Ovens or Paint Baking Oven removes the moisture from water-based coatings and adhesives. Paint Drying Ovens are also removes water from the surface or interior of products with the help of thermostatic controls in case of electrical heating and temperature controllers operating solenoid valves in case of steam, gas and oil heating.An Industrial Paint Curing Oven cures dries the paint through the heated air that is re circulated in the Oven. This is generally done by having a heating chamber where air is heated and the heated air is circulated inside the Paint Curing Oven chambers by means of fans.Why Industrial Paint Curing Oven required?The provision of a Industrial Paint Curing Oven in a production shop area ensures: speeding up of the paint drying operation Improved quality of product Increase in the durability of the product Economizing the cost of painting the product and lastly Dust free product. Criteria of selection of Type Industrial Paint Curing Oven:The type of an Industrial Paint Curing Oven is determined by many factors, such as- Total heating capacity Shape of the object to be dried in the Paint Drying Oven Type and thickness of insulation required in the Paint Drying Oven Adequate exhaust arrangement for removing the solvent fumes of Paint Drying Oven Proper arrangement for location of burners and heaters in the Paint Drying Oven to ensure uniform heating. The arrangement of burners or heaters in a Paint Drying Oven should ensure the provision of uniform heating across the cross section and the length of the Paint Drying Oven.Paint Drying Ovens are generally constructed out of mild steel sheets with strengthening members and supports the outside wall of Paint Drying Oven and aluminum sheets on the inside wall of Paint Drying Oven, with an adequate thickness of insulation in between.During regular operation of Paint Drying Oven, the temperature inside the Paint Drying Oven is automatically maintained at a pre-determined level with the help of thermostatic controls in case of electrical heating and in the case of steam, gas and oil heating by temperature controllers operating solenoid valves.Improved quality and durability of paint finish can be achieved by providing proper facilities for staving the painted components. This requires a Paint Drying Oven of the right type, size and having the correct staving temperature. In many cases, an improvement in the finish and economics in paint costs can be achieved for users of air drying paints, by adding staving facilities in a Paint Drying Oven and changing over to enamel paints

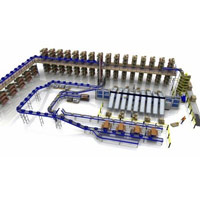

Best Deals from Overhead Conveyor Ovens

Powder Coating Oven

Get Price Quote

Our facility in Pune(India) is well connected by a variety of modes of transportation. Thus, we are able to reach customer anywhere. Buyers can stay rest assured for damage-free products from our end as we make use of quality packing material. We also fulfill different packing requirements of the clients such as customized or standard.

Hot Air Oven

Get Price Quote

1 Piece(s) (MOQ)

Features: Advance PID Type Dual Display Temperature Controller with settable Overshoot Alarm. Specially designed fins type Air Immersion Heaters Heavy Duty Solid State Relay For Heater Supply Door Sealed with Silicon Rubber Gasket Air Circulation System to maintain uniform temperature inside the chamber Safety Thermostat ( In GMP Models only) Various Sizes are available.

Industrial Oven

6,000 - 200,000 Per PIECE

1 Piece (MOQ)

Annealing Oven

250,000 Per unit

1 unit (MOQ)

SS Drying Oven

150,000 Per Piece

Vacuum Oven

47,000 - 48,000 Per Piece

Hot Air Oven

Get Price Quote

Technical Specifications of Ovena] Oven Structure: -oven Will Be Made Out of Steel Fabricated Structure & Will Having Heating Chamber with Slits for Hot Air Circulation. Suitable Thermal Insulation Will Be Given to Maintain Out Side Surface Temp. At Around 40 Degree Centigrade.b] Heating System: -24 Kw, U Shape, Ss Finned Air Heaters Will Be Provided in the Chamber. Hot Air Will Be Circulated Through the Slits On Top & Bottom Portion of Heating Chamber & Return Air Will Be Again Fed to the Suction of Air Blower.c] Temp.control System: -suitable Digital Pid Temp.control Will Be Provided to Maintain the Temp. Inside the Heating Chamber Between +/- 2 Degrees.d] Top Door System: -the Top Door Will Be Hinged Type & Will Be Operated By Two Pneumatic Cylinders. the Door Will Be Having Two Opening Positions.e] Control Panel: -built-in Control Panel Will Be Provided for Heater & Blowercontrol. the Control Panel Will Be Having Siemens Switchgear & Pid Controller. the Panel Will Be Having all the Safeties & Protections.

electric infrared ovens

Get Price Quote

electric infrared ovens, electric infrared radiator, Gas Infrared Burner

Automatic Furnace Oven

Get Price Quote

Automatic Furnace Oven, wire forms springs, Pvc Welding Machine

Pizza Conveyor Oven

Get Price Quote

Pizza Conveyor Oven, Industrial Robotic Automations, carton Making Machine

Hot Air Universal Oven

Get Price Quote

Hot Air Universal Oven, Horizontal Paper Electrophoresis System