Cryogenic Vaporizer

35,000 Per Piece

1 Piece (MOQ)

We are the leading manufacturers and suppliers of the Cryogenic Vaporizer.

N2 PSA Plant

950,000 Per Piece

1 Piece (MOQ)

Best Deals from Oxygen Gas Plant

Pressure Swing Adsorption

550,000 Per piece

Pressure swing adsorption (PSA) is a well-established gas separation technique in air separation, gas drying, and hydrogen purification separation. Recently, PSA technology has been applied in other areas like methane purification from natural and biogas and has a tremendous potential to expand its utilization.VEPL deals in all types of Adsorption as per client requirement. All material of construction available in this equipment.

Suction Manifolds

Get Price Quote

Located in Pune(India), we are actively involved in bringing forth a high quality array of products in the market. Be it online payment or offline, we make possible for you to make trade transactions as per your convenience. We offer both offline and online mediums to make payment. This is suction manifold. Its aluminium product. Used in some automobile industries, as well as different industries. there is different types of manifolds.

Air Header

Get Price Quote

Cylinders Cascade

Get Price Quote

We offer high quality Cylinders Cascade. A group of gas cylinders are interconnected by high pressure piping to form a single gas storage unit and are called a cascade. The cylinder cascade may contain from 6 to 600 gas cylinders.Widely used in various industries such as automotive, the primal benefit of the product is that it avoids individual handling of cylinders and adequate gas quantity resulting in better production planning and cost savings to the user.

Paramagnetic Oxygen Analyzer

Get Price Quote

MS OX 27 Oxygen Sensor

Get Price Quote

Oxygen Indicating Analyser flame proof / weatherproof 4-20mA output Specification Display : LED Range : 0 to 21% Resolution : 0.1% Accuracy : 2% of FS Response Time : 14 ± 2 Seconds Linearity : 0.21 ± 0.02 Operating Temperature : 5 to 40°C Operating Pressure : 811hPa to 1216 hPa Operating Humidity Range : 10 to 90% RH ( Non condensation) Output : 4 to 20 mA Supply : 24 VDC Enclosure : Flameproof ( Gas Group IIA / IIB Mounting : Wall Mounted

Dissolved Oxygen Transmitter

Get Price Quote

SALIENT FEATURE• Online Measurement• 2 wire System• 4-20mA DC Output• Auto/ Manual Temperature Compensation• Simple Operating interface with basic pictographs• Easy installation with per Assembly empty Enclosure & Plug in terminal• Online Indication through LCD Display• Protection Class IP- 65 DESCRIPTION: MicroSet series Micro- DO 211T are dissolved oxygen transmitters used for various industrial applications. It can accept input from DO electrode the signal is transmitted in the form of electrical 4 - 20 mA signal. The online indication is provided through LCD. Span/Zero adjustments are easily accessible.

Gas Pipeline

Get Price Quote

Liquigas is one of the listed gas pipeline companies in India. Our recognition in the sector goes out to touch many other horizons and as well makes us a profound name in world, as much as our profound presence as the best and most reliable gas pipeline installation and manufacturers in India. To become a frontline producer and of the top installation provider of gas pipelines, we have long stressed on three attributes:

Oxygen Generation Plant

Get Price Quote

When it comes to Oxygen Generation Plant, there are only a few alternatives to us. We offer highly efficient and high standard Oxygen producing plant which is available in standard as well as customized configurations. This Oxygen generator is used to release Oxygen which is produced by a chemical reaction. This finds application in aircraft, submarines, mine rescue crews, fire fighting experts etc. Some of the important features include durability and efficiency. We are one of the authentic Oxygen generating plant exporters from India.

Air Header

Get Price Quote

10 Piece (MOQ)

Equipment structure can be done according to customer requirements.

lpg bottling plants

Get Price Quote

we undertake turnkey contract for bulk installation of lpg bottling plants for filling lpg cylinders. These are sophiticated plants with or without carousel. We also provide special instrumentation for complete automation to enable faster and accurate cylinder filling. bottling plant is a plant where beverages are put into bottles with a cap. These bottles are widely used for storage purposes. liquefied petroleum gas (lpg) consists mainly of propane, propylene, butane, and butylene in various mixtures. However, in the united states, the mixture is mainly propane. It is produced as a by-product of natural gas processing and petroleum refining. The components of lpg are gases at normal temperatures and pressures. lpg bottling plant is a plant where lpg is put into bottles for storage. The plant has the facility to recieve bulk lpg by pipeline from a reliable source or any area. This is the safest and the cheapest way of transporting bulk lpg. the plant is equipped with hydraulic cylinder testing equipment for periodic testing of the cylinders. To ensure safe and accurate filling of the cylinders well experienced technical people should only be employed in the working of the plant. tips while working with lpg bottling plant the filling machines should be provided with pneumatic cut off system to automatically cut off the lpg supply when the cylinder is filled. the filling pressure should not exceed design pressure of the liquid. cylinders have a standard weight and all cylinders should be checked for their weight after they are filled. the compact valve tester should be calibrated to detect leakage from the cylinder. defective cylinders should be evacuated and evacuation should be done either through one or two vessels. From these vessels lpg is transferred to the storage vessels through a pump. security caps should be provided while performing any test with lpg. the sequence of operation should be strictly followed. to avoid undue accumulation the cylinders should be immediately shifted to storage after filling. the quality control checks at the bottling plants are carried out at 3 stages: spurious cylinders, cylinders with missing o-rings and cylinders due for pressure testing. post-filling quality control checks - in the post-filling checks, it is ensured that all the cylinders filled on the automatic cut-off weighing scale/filling machines are subjected to 100% cross- checks for weight. statistical quality control checks - these checks include all pre-filling and post-filling checks in addition to checking the quality of the seal.

Single Row Manifold

Get Price Quote

100 Bar (MOQ)

Optical DO Analyzer

Get Price Quote

The LXT-220-D08 optical dissolved oxygen sensor uses a fluorescence quenching method to determine the oxygen concentration in water. The use of this Optical Dissolved Oxygen method by the LXT-220-D08 minimizes maintenance, increases reliability and improves the long term accuracy of the measurement. Combine this improved measurement technology with the rugged, easy to install design and the LXT-220-D08 provides the best solution for long term measurements in aeration basins, aquaculture and all types of environmental water. Features • Optical technologyMinimum maintenanceLong maintenance intervalsStable measurementMaximum measurement accuracy• No flow neededMeasurement possible in still water• Intelligent sensorSelf monitoringStorage of calibration data in sensor• Digital data transmissionInsensitive to electromagnetic interferences• Dual Channel CapabilityLower Cost - 2 DO8 sensors per analyzer

Dissolved Oxygen Analyzer

Get Price Quote

Industrial Gas Pipeline

200 Per Meter

Air Header

Get Price Quote

An air header is used for air distribution networks for centralizing several connections. It saves considerable installation cost & space. In a standard air header 10 outlets are available.

lpg bottling plant

Get Price Quote

PSA Oxygen Gas Plant

1,900,000 Per Piece

lpg bottling plant

1,000,000 Per Piece

5 Piece (MOQ)

Air Header

Get Price Quote

Gas Manifold Systems

Get Price Quote

gas filling machine

Get Price Quote

lpg bottling plants

Get Price Quote

WE UNDERTAKE TURNKEY CONTRACT FOR BULK INSTALLATION OF LPG BOTTLING PLANTS FOR FILLING LPG CYLINDERS. THESE ARE SOPHITICATED PLANTS WITH OR WITHOUT CAROUSEL. WE ALSO PROVIDE SPECIAL INSTRUMENTATION FOR COMPLETE AUTOMATION TO ENABLE FASTER AND ACCURATE CYLINDER FILLING. Bottling plant is a plant where beverages are put into bottles with a cap. These bottles are widely used for storage purposes. Liquefied petroleum gas (LPG) consists mainly of propane, propylene, butane, and butylene in various mixtures. However, in the United States, the mixture is mainly propane. It is produced as a by-product of natural gas processing and petroleum refining. The components of LPG are gases at normal temperatures and pressures. LPG bottling plant is a plant where LPG is put into bottles for storage. The plant has the facility to recieve bulk LPG by pipeline from a reliable source or any area. This is the safest and the cheapest way of transporting bulk LPG. The plant is equipped with hydraulic cylinder testing equipment for periodic testing of the cylinders. To ensure safe and accurate filling of the cylinders well experienced technical people should only be employed in the working of the plant. Tips While Working With LPG Bottling Plant The filling machines should be provided with pneumatic cut off system to automatically cut off the LPG supply when the cylinder is filled. The filling pressure should not exceed design pressure of the liquid. Cylinders have a standard weight and all cylinders should be checked for their weight after they are filled. The compact valve tester should be calibrated to detect leakage from the cylinder. Defective cylinders should be evacuated and evacuation should be done either through one or two vessels. From these vessels LPG is transferred to the storage vessels through a pump. Security caps should be provided while performing any test with LPG. The sequence of operation should be strictly followed. To avoid undue accumulation the cylinders should be immediately shifted to storage after filling. The bottling plant has its own system of stringent safety and quality control checks built-in at different stages The quality control checks at the bottling plants are carried out at 3 stages: spurious cylinders, cylinders with missing O-Rings and cylinders due for pressure testing. Post-filling Quality Control Checks - In the post-filling checks, it is ensured that all the cylinders filled on the automatic cut-off weighing scale/filling machines are subjected to 100% cross- checks for weight. Statistical Quality Control Checks - These checks include all pre-filling and post-filling Checks in addition to checking the quality of the seal.

Manifolds AND Fittings

Get Price Quote

We offer manifolds and fittings that are used for mounting metering cartridges. These zinc plated steel blocks are offered in models LMF-1 to LMF-9. Every centralized lubrication system are offered with straight connector, elbow, banjo assembly, tee block, cross block, connector blocks, nuts and plugs, clamps and olive. Applications :- Mounting metering cartridge

car gas filling LPG Skid

Get Price Quote

Introduction :- We manufacture LPG Skid for filling LPG gas in cars and other vehicles. There are various models available with storage tank capacity ranging from 3000 Liters to 100000 Liters and with the choice of single or double nozzle LPG dispenser . This is a custom built ready to install plant. The unit is easy to install and operate and much cheaper as compared to other plants .The unit comes with all safety features as per norms.

Dissolved Oxygen Analyzer

Get Price Quote

We bring forth highly efficient Dissolved Oxygen Analyzer in the market. Portable Dissolved Oxygen Analyzer is used for measuring oxygen level in water that causes corrosion of components and pipes. We are counted as one of the prime Dissolved Oxygen Analyzer System Exporters in India. Uses Boiler feed waterEconomizersCondensers Benefits Range – 0 to 2000 PPBUser–friendly menu–based programmingEasy to installLong–life membranes pre-mounted on retaining caps to suppress any delicate membrane handlingTwo–point calibration: zero & slopeFast calibration procedure: from ppm level (air) to process ppb values in less than 15 minutes!Two smart analog outputs (measurement/temperature) with automatic recognition of the analyzer statusFour relays for high/low limits, system error and timer Applications Boiler feed waterEconomizersCondensersAll thermal equipment using water as a heat transfer liquidMeasures DO effectively with repeatability of +/- 0.5 ppb

Vaporisers for Liquid Carbon di oxide

Get Price Quote

We manufacture Atmospheric vaporisers for Liquid Carbon di oxide of various capacities ranging from 50 to 5000 Nm3/ Hr . The vaporisers are made of aluminium finned tubes with multi passes for better efficiency and comes with all safety features as per norms .

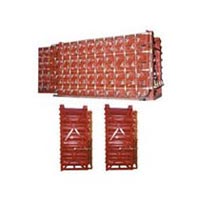

Cryogenic Vaporizers

Get Price Quote

Aluminum Star Fin Vaporizers follows unique honeycomb assembly procedure, which eliminates weld cracks during operation, transportation and handling. The performance of ambient air vaporizers is subject to many factors. These include flow, duty-cycle, ambient temperature, relative humidity, freeze period, altitude wind, solar radiation, operating pressure and proximity to adjacent structures. The effects of average solar and wind conditions are not included in the conditions of 21 °C and 70% relative humidity. Specific conditions may vary considerably for a particular application, thereby affecting performance.