Tubular Structures

Equipped with 3 axis servo drive CNC bending machines, we are capable of processing both ERW and CEW metal tubes up to 65 mm in diameter and 4 mm in wall thickness. Our high precision machines can process 180° bends with an accuracy of 0.2°. High precision special purpose machines with an accuracy of 25 µm for drilling and scooping applications give rise to highly accurate weld joints. We have both robotic and manual MIG welding facilities, with robotic intervention in any weld line as high as 80%. Robotic welding reduces human dependency and as a result provides consistent quality in our products. Panasonic and Fanuc robots are installed on our welding lines, and robot installation commissioning as well as critical tasks such as PLC programming are done in house by our highly capable maintenance teams. Positioning of the tubes is extremely critical, and high precision welding fixtures are designed and made. Rigorous process engineering and continuous improvement of the lines has made it possible to cater to very high volumes of production, higher even than 1200 complete two wheeler frames every day. Our welding laboratory makes it possible to test weld strength, penetration, nugget and micro-structure regularly and ensure sustenance in quality. Capacity to provide solutions from tube bending to high precision welding, to handle very high production volumes and to supply excellent quality products has helped us support our customers every time.

...more

Sheet Metal Assemblies

Sheet metal stamping is one of our core competencies. Sheet metal stamping is a metal forming technique through which sheet metal goes through different stages forming and cutting until an end product is reached. An intricate assembly of various sheet metal parts makes up the body, frame and outer panels of any vehicle. With a stamping capacity ranging from 1600 T to 150 T, and a wealth of experience, we are able to manufacture a wide variety of products- from complex BIW modules to small intricate brackets, from large body panels to high strength chassis frames; and cater to a wide variety of products- from 2 wheelers to heavy commercial vehicles, from passenger cars to non-auto applications. As a result, we are able to support a varied customer base and product segment- 2 wheelers, cars and utility vehicles, commercial vehicles, farm equipment and non-auto applications. Heavy duty hydraulic presses enable us to work with high strength steels up to 780 MPa. We have 4 heavy duty press shops across all plants in India, and 5 medium and light duty press shops. All our heavy duty presses are imported from Germany, and installed by our highly trained maintenance teams. Pan India set-ups and a varied customer base allow our production and quality teams to exchange good practices and implement them. Our fabrication lines are PLC controlled, and in house welding laboratories conduct routine nugget tests to ensure excellent quality products. Hemming is done robotic-ally with precision part positioning.

...more

Design & Development

The Panse engineering and design centre is located in Pune. We take pride in adding value to the product early on – with in house product design, process design, tool design and tool manufacture. Through backward integration, customer interaction begins right from the start of the project. Feasibility studies, formability analysis and tool design are done using latest software. Tool manufacturing takes place in a phased manner on in-house try-out presses. With capable and experienced engineers, programme managers and die makers at its disposal, the Panse engineering centre has undertaken and seen through to completion many challenges in light-weighting, working with high strength steels, newer materials or innovation in tool design.

...more

AVS Parts

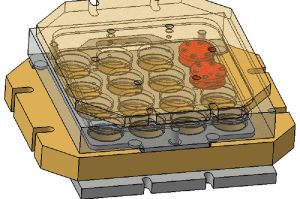

Rubber to metal bonded parts are important in ride and handling for any vehicle, and isolate the chassis from vibrations. They stabilize the vehicle against various impact loads produced by the tires during longitudinal braking, acceleration, cornering forces and braking. They maintain wheels in their proper positions with respect to the road surface while turning. Autocomp Corporation has a joint venture with Ferrabyrne UK, who are experts in rubber to metal bonding technology for CV, passenger car and railway segments. The joint venture company (Ferrabyrne Autocomp Suspension Technologies) is located in Pune. The AVS expertise of Ferrabyrne coupled with the engineering and SCM strength of Autocomp Panse has enabled the company to design, develop and manufacture AVS parts and assemblies. The plant is fully equipped and operational with imported equipment- moulding machines up to 400T and state-of-the-art testing machines along with rubber mill and process equipment.

...more

Assembly Engine Cover

motorcycle chassis

Bracket Tail Pipe Hanger from Panse

Radiator Support Panel from Panse

Tractor Rear Wheels Fender

Be first to Rate

Rate This