Ventury Conveying System

Indpro Ventury Educator is a static device without any moving parts, which injects solids in high pressure gas for onward pneumatic conveying. FEATURES High pressure gas passes through the sonic nozzle were sonic velocity is reached Low pressure gas gets sucked through solids feed inlet due to low pressure created ahead of sonic nozzle Solids and secondary gas get accelerated & mixing takes place in the mixing zone, gas velocity in this zone is high Expander/diffuser provided converts this velocity pressure into static pressure at the outlet The injector entrains only that much quantity of solids & secondary gas which Venturi Injector and downstream equipment can handle, it is therefore a self-regulating device Venturi Injector always works at systems maximum rated capacity The Venturi nozzle and, when coupled with a high-pressure blower, is the primary source of motive power for a trim / material conveying system The educator allows for movement of material in continuous form (edge trimmings) and without any moving components in the conveying air stream

...more

Vacuum Conveying System

The Pneumatic Conveying is necessarily custom made conveying system & based on product characteristics, particle size, throughput capacity, number of sources and number of destinations. Each pneumatic conveying system is designed & customized as per the application popularly known as custom conveyor system.The provided solution is assured to be the best pneumatic conveying system solution for the application. Being the application experts & pneumatic conveying system manufacturer, we always assure to deliver best of both the worlds (commercial & technical worlds).

...more

Spent Grain Conveyor

Indpro have launched revolutionary wet spent grains conveyors have been especially designed for the modern brewery and allow reliable transport from the lauter tub or mash filter to the silo plant. FEATURES Indpro systems are simple yet efficient systems that help you get rid of your spent grain Indpro has the best solutions for wet spent grain conveyors, dryers and silo systems The new generation of Indpro spent grain conveyors are designed for the modern brewery These systems meet today’s demands for operational safety, low air consumption, easy cleaning and maintenance We design a complete spent grain removal system that suites your needs Indpro spent conveyors operate on the principle that spent grain enters the conveyor through the top, is compressed by a screw, and then pushed through the spent grain piping pneumatically They offer a simple, quiet and efficient way to convey spent grain

...more

Speciality Filter

Commonly known as dust collectors. Indpro in association with Herding GmbH are pleased to offer a revolutionary sintered plate filter element based pulse jet filter used to separate dust particulates from fugitive dust emitting sources & process off gas. FEATURES They have a feature of continuous operation with a built-in facility for automatic regeneration of filter elements by compressed air without plat shut down This cleaning process is controlled through an electronic timer in DP mode or preset mode Today they are the most efficient solution, capable of achieving emission levels as low as 0.1 mg/Nm3, with an filtration equivalence HEPA E-11, having FDA approval ideal for Product recovery The filtration mode is “Surface Filtration” due to PTFE coating on filtration side enabling a constant air flow & pressure drop conditions The expected filter life possibility up to several years and compact overall construction are the hallmarks of our product range These filters are customized & can be designed for handling normal & explosive dusts Medium like hybrid mixtures of explosive gas with explosive dusts can also be handles with constructive protection measures & several safety features We have offered high pressure, CIP (Cleaning in place), sanitary finish specialty filtration solutions to various industrial demands / applications SPECIFICATIONS The complete mechanical assembly consists of dirt gas section & clean gas section divided by a filter mounting plate Dirt section comprises a casing which houses filter elements & hopper with a filtered dust discharge device The clean gas section houses assembly of blow tubes which are connected externally to an assembly of pulse valve & compressed air manifold

...more

Scrubber System

INDPRO’s SWEET SCRUB is a revolutionary design to achieve consistency in sticky products such as Sugar. SWEET SCRUBTM is a unique cyclone & scrubber design ensures that sugar does not stick to it and is separated effectively. FEATURES Dilute Phase pressure conveying Up to 15 TPH capacity Up to 30 meter (100ft) conveying distance All SS 304 construction Internal mirror finish Noise reduction blower (Optional) CIP enabled Minimum downtime No Sticking, No Choking, No Product loss Minimum suspended particle discharge Additional safety equipment not required

...more

Screw Conveyor

Tubular Screw Conveyors and Feeders are manufactured from carbon steel with suitable surface finishing. They consist of a tubular trough equipped with at least one inlet and outlet spout, a welded flange at each tube end, helicoid screw flighting welded on a Centre pipe with a coupling bush at each end, two end bearing assemblies complete with self-adjusting shaft seal, a number of intermediate hanger bearings depending on the overall length of the screw conveyor. FEATURES Tubular Screw Conveyors are equipped with a gear motor appropriate for the application The modular TU Tubular Screw Conveyor and Feeder system is highly versatile offering a variety of standard solutions for handling of powdery or granular materials SPECIFICATIONS TU Tubular Screw Conveyors come in a medium heavy-duty design only TU Screw Conveyors are available with ATEX, Zone 22 certification Depending on the characteristics of the material, different models of conveyors or feeders are available in applications such as concrete production (for fly-ash, filler dust, silica fume), premixed building materials (dry plasters, sand, cement, additives), glass processing (calcium carbonate, soda, sand, etc.), foundries (sand, bentonite), and many others

...more

rotary sifter

Indpro Rotary Sifters are designed to classify, scalp or de-lump dry powders or granules. These are ideal for sizing, sifting, scalping and classifying applications. PROCESS The material to be sifted is fed into the cylindrical screen by a screw mounted on the rotating shaft The rotating cylindrical screen with rotates at a higher RPM compared to a series of paddles, which rotate inside the screen without contact, centrifugally force the material against the screen to break up any soft agglomerates Sub-sieve material (fines) that pass through the screen discharge into a collection hopper at the base of the machine Oversize material and hard lumps (that cannot be broken) traverse down the length of the screen to the overs outlet An anti – blinding brush continuously clean the cylindrical wire mesh of the sieve, ensuring maximum separation efficiency

...more

Rotary Air Lock Valve

Rotary Airlock Valve (RAV) is the equipment which is fitted below the Bag Filter, Cyclone etc. The main function of the RAV is to lock the air and discharge the dust / powder. In the Bag Filter system, there is negative pressure in the Bag Filter. So, at the powder discharge point if there is any air leakage the powder will not fall down. So, to restrict the leakage we provide the Rotary Airlock Valve FEATURES RAV consists of a stator & rotor The radial & axial clearance is between 0.1 to 0.3 mm The rotor has vanes (6 or 8) welded on the shaft The rotor is mounted on the bearings at both the ends of the stator A Geared Motor is provided to rotate the rotor Since the clearance between rotor & stator is so low, air leak is very minimum and it delivers only powder

...more

Powder Transfer System

Indpro makes PTS system is an efficient, reliable method of transferring and dispensing bulk powders, granules. This system is a significant enhancement to any conventional, mechanical or pneumatic material conveying process and provides total dust free means of material transfer. FEATURES Advantage over conventional systems especially in the charging of different vessels Compact design and modular construction Use of TCN end connection wherever feasible for ease of assembly Powder transfer and dispensing is by a clean and reliable method Powder can be transfer in Reactor / vessel without opening, maintaining it atmosphere Powder can be charged into reactor under pressure / vacuum or with solvent present into the vessel Can be used to transfer materials with wide range of properties Total Discharge without wastage Absence of Oil or grease usage avoids material contamination Dust free system due to operation on vacuum principle Vessels under vacuum or pressure can be charged Enhanced productivity with inbuilt safety and hygiene are highlights of this system This system facilitates, reduction in batch time & total process integration SPECIFICATIONS Powder feed hopper / Powder suction tool PTS vessel with automated valves & regeneration type filter Vacuum pump Intermediate piping & fittings Control Panel

...more

Pneumatic System

The provided solution is assured to be the best pneumatic conveying system solution for the application. Being the application experts & pneumatic conveying system manufacturer, we always assure to deliver best of both the worlds (commercial & technical worlds).

...more

Pneumatic Conveyors

The Pneumatic Conveying is necessarily custom made conveying system & based on product characteristics, particle size, throughput capacity, number of sources and number of destinations. Each pneumatic conveying system is designed & customized as per the application popularly known as custom conveyor system.

...more

Pneumatic Conveying System

The pneumatic conveying is necessarily custom made conveying system & based on product characteristics, particle size, throughput capacity, number of sources and number of destinations. Dilute phase is a suspension flow wherein the material to be conveyed is introduced into a moving air stream inside a pipeline. FEATURES The dilute phase conveying system uses low-pressure air at pressures less than one bar in case of pressure conveying and (-) 5000 mm in case of vacuum convening, which is generated by positive displacement type roots blowers or by centrifugal blowers For the material to remain in suspension there is a minimum conveying velocity which varies for different materials. The quantity of material that is fed into an air stream is also dependent on material characteristics like bulk density, particle size, sieve analysis, frequency distribution etc Generally, the material to air ratio varies between 3 to 10 kg of material to kg. of air Conveying velocities are in the range of 18 to 28 m/sec depending on the product characteristics

...more

oil seal machine

Magnetic Separator

A powerful permanent magnetic field uniformly covers the entire drum width to ensure maximum tramp iron removal. FEATURES Indpro classifier removes coarse and fine impurities from the grain by sieving. The smooth stainless-steel shell with single wiper strip assures positive tramp iron discharge and a minimum of product carryover on powdery or cohesive materials They are available in 12-36" (305-915 mm) diameters Replaceable auxiliary shells are available are recommended where highly abrasive materials are being handled

...more

Inline Weigh Scale

We have installed thousands of Net Weighers. This is with the latest state-of-art technology, Mechanical design and with its own dedicated Microcontroller MCB+. We have fastest Servo Feeder Net Weigher with 2200-2400 bags per hour for free-flowing granules depending upon product characteristics. FEATURES Net weigher is built in different material depending upon product and application Having wide range of product feeding systems depending upon the product characteristics Net weighers are versatile and suitable for wide range of products such as Grains, Plastics, Cattle feed, Fertiliser, Pallets, Flakes and Speciality chemicals We in association with PAYPER offer Net weigher with Fully Automatic Bagging Line or With Semi Automatic Bagging line depending upon application and customer requirement Net weigher can be upgraded with Fully Automatic Bagging System if needed Weighing into weigh hopper prior to filling

...more

industrial vacuum sealer

We have streamlined inventory system and spacious warehouse that assist us in meeting the voluminous requirements of the clients and that too in the stipulated time span. With the latest facilities, we efficiently ensure year round availability of the products. Catering to the voluminous and urgent requirements of our clients from Maharashtra(India); count on us to avail the same

...more

Flap Diverter

Indpro Diverter Flap Valves are manufactured using CNC laser cut portion. The flap is either activated by a manual lever, a pneumatic or an electric actuator. FEATURES Indpro Diverter Flap Valves have one inlet and two outlets for the diversion of the flow of powdery or granular materials. Materials used enable quick cleaning and maintenance. Rubber type seal ensure minimum leakage & minimum residue

...more

Flexible fabric silos

These “HIGH-TENACITY” TREVIRA containers, suitable for indoor storage, consist of a large reinforced bag made of breathable dust-proof material and equipped with a filtering cover for venting and filtering air during the loading operations. FEATURES Lower raw-material costs Raw material always in the best condition for use and storage, no condensation and as little wastage as possible Construction of tailored storage facilities to exploit the storage area in the best possible way, occupying even narrow and otherwise unusable spaces Cost-effectiveness. Belt replacement - The belt is specially designed to cope with maximum rotation speeds. No component of the machine needs to be removed in order to change the belt SPECIFICATIONS They are made to measure and the base can be square or rectangular, to meet even the most demanding storage requirements The tubular structure is hot-galvanised The storage capacities range from 3 to 60 cubic metres This type of container is supplied complete with its own loading pipe and vibrating extractor made of AISI 304 stainless steel, ideal for pneumatic and/or mechanical extraction systems Several optional accessories are available on request : Inspection window Bladed or induction-type level indicators Weighing systems with visual control and acoustic indicators of the quantity stored, etc

...more

Dual Tunnel Diverter Valve

Dual Tunnel Type Diverters have been specially designed to route powders and pellets with minimum degradation in pneumatic conveying systems. FEATURES The Indpro diverter is applied in the chemical, pharmaceutical, plastic, food and other related industries The Indpro diverter consists of an Aluminum housing and end covers in which a plug with two pipes is installed All product contact surfaces are made from SS 304 Three approved silicone seals guarantee the sealing between housing and plug The body is pressure tight, so ensuring no leakage to atmosphere The standard diverter can be used in systems with positive pressures up to 3 bar g (static seals) The sizes 50-150 are optionally available for pressures up to 6 bar g (inflatable seals) The Indpro dual tunnel diverter valve is supplied with a complete electro pneumatic control system, including solenoids and inductive position sensors The standard diverter can be used for product temperatures ranging from –25 °C up to +80 °Cat ambient temperatures of –10 °C up to +40 °C. Versions for higher temperatures are available on request

...more

Destoner Equipments

Indpro Destoner comes to rescue, for efficient removal of high-density matter from grains. The contamination can be stones, metallic particles, glass etc. PROCESS The product fed through an air shut-off gate after preliminary cleaning by gravity The product passes on to an inclined oscillating deck. The deck is designed as screen; through which an upward current of air is passed with the help of a blower. This results in fluidizing the product Due to their different specific gravities, the heavy particles such as stones sink to the bottom of this layer of fluidized material, while the lighter particles supported by the cushion of air, float on top The oscillating action of the screen causes the heavy particles to work their way to the upper end of the deck There is an adjustable counter of air, this causes the final separation of heavy particles from light material and the stone discharged The throughput capacity vary according to product to be handled and contamination. Variety of products can be handled – Rice, Wheat, Millets, Sorghum, Barley, Malt etc. Typically the capacity ranges from 8 TPH to 20 TPH The air volume can be adjusted to achieve the optimal degree of separation

...more

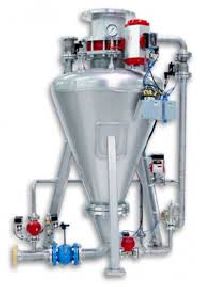

dense phase conveying systems

Dense Phase Conveying System is recommended for conveying high capacity for longer distances normally at lower speeds and a material to the ratio as high as 8 times of Dilute Phase Systems. The operating pressure of the system is generally higher. These systems operate below minimum suspension velocity and the materials move along the bottom of the pipe. We have a wide range of dense phase transporter that is designed as per the accepted industry standard and is widely used across various industries. High on reliability and durability, these can also be fabricated as per the specific requirements of our clients.

...more

Conventional Hose Filters

Commonly known as bag houses, dust collectors, pulse jet bag filters. Indpro’s fabric dust collectors use filtration to separate dust particulates from dusty gases. They have a feature of continuous operation with a built-in facility for automatic regeneration of filter elements. Today they are the most efficient and cost effective solution, capable of achieving emission levels as low as 5 mg/Nm3. FEATURES Inertial collection - Dust particles strike the fibers placed perpendicular to the gas-flow direction instead of changing direction with the gas stream Interception - Particles that do not cross the fluid streamlines come in contact with fibers because of the fiber size Brownian movement - Submicrometre particles are diffused, increasing the probability of contact between the particles and collecting surfaces Electrostatic forces - The presence of an electrostatic charge on the particles and the filter can increase dust capture

...more

Container Loading System

Pneumatic Bulk Container Loaders provide the ability to make a 90 degree transfer of the product from a low clearance silo into the back of a marine shipping container. They load in a very clean way pellets, granules and powders. FEATURES The complete system consists starting from the upstream end: a rotary valve feeder attached to the discharge spout of the silo that doses the product into a conveying lance under positive pressure created by a blower package upstream. The air is clean and dry If the pneumatic system is the Dilute Phase type, the air is conveyed at high velocity and low pressure, therefore the pellets, granules or powders enter the bulk container liner at high velocity but in small amounts If the pneumatic system is the Dense Phase type, the air is conveyed at high pressure but low speed, therefore the pellets, granules or powders enter the bulk container liner at low speed but in big quantity batches. This method is much faster than the dilute phase system but requires high pneumatic pressure availability For powder type products, the bulk container liner is equipped with a ventilation port that returns the dust to a bag/filter house in a closed loop system Pneumatic Bulk Loading systems achieve a high usage of the container payload volume but they are high energy users Ideal to be installed under silos with low clearance Dilute Phase (Low pressure/High Velocity) or Dense Phase (High Pressure/Low Velocity) Best fit for pellets, granules and powders that require maximum cleanliness High efficiency in container volume usage Consists of rotary valve feeder, conveying lance, blower package, compressor, air dryer and dust collection system if applicable

...more

Closed Loop Conveying System

Indpro Closed Loop Conveying (ICLC) System is the ideal method of pneumatically conveying hygroscopic, sterile, perishable and hazardous products such as Chemicals, sugar, starch, potato / milk powder and oxidising powders, Chemicals, where product exposure to unconditioned gas can cause product degradation and introduce material handling problems. Same system can cater to products that are sensitive to contamination, application such as baby food, pharmaceutical industry, highly explosive material etc. FEATURES Sealed System : No airborne contaminants Contained emissions Clean enclosed method of conveying Re-circulating gas = Economic Dry Air Conveying Economic inert Gas Conveying Multiple destinations & single common filter Nitrogen / Inert Gas Conveying : Hazardous products transported safely Explosion panels and venting eliminated Economic conveying by recirculation – minimal gas usage Dry Air Conveying : No caking/agglomerating Microbiological growth inhibited – ideal for food products Product stays in good condition dry & free flowing Reduced maintenance & cleaning No condensation or need to lag/insulate pipes Improved filter performance Sterile Air Conveying HEPA filtered air is introduced to the system to ensure biological contamination is eliminated

...moreBe first to Rate

Rate This