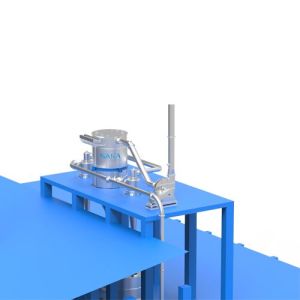

Vacuum Conveying System

225,000 Per Piece

01 Piece (MOQ)

Pneumatic Conveying System

Get Price Quote

Pneumatic conveying systems are basically quite simple and are eminently suitable for the transport of powdered and granular materials in factory, site and plant situations.

Best Deals from Pneumatic Conveyors

Pneumatic Conveying System

Get Price Quote

Lean Phase Pneumatic Conveying system, Dense Phase Pneumatic Conveying system Plutontek, Designs & Manufactures, pneumatic conveying systems as a tailor made product, to provide solutions for bulk material handling. Design of system depends on the product characteristics, particle size, capacity, number of inlet sources and number of outlet / destinations, etc. Each pneumatic conveying system needs to be designed & customized as per the application given. Prime mover for conveying the product can be Roots blower, Compressor, Centrifugal blower, Centrifugal fan or Radial blower, depending upon bulk density of the material to carry, Length of the system, flow rate required and pressure required at outlet. System can run on both negative / positive pressure, depending upon the situation. At Plutontek, we have to consider all the given parameters to design the system and has to offer the optimum solution to customer in order to achieve economies in intial cost as well as running cost You can rely on us for all your customized requirements of : Dense Phase Pneumatic Conveying systems Lean Phase Pneumatic Conveying systems / Dilute Phase Pneumatic Conveying systems Combined Lean Phase and Dense Phase Pneumatic Conveying systems "Dense Phase Pneumatic Conveying system : The main principle of a dense phase conveying system is to slow down the velocity of the product in the pipe conveyor to a point that is below the speed at which the product breaks or degrades. At low velocities, the product lies for periods of time in the bottom of a horizontal line and it is blown under pressure to the discharge point in slugs or plugs. The dense phase pneumatic conveying systems uses low volume, medium pressure air stream and relies on a continuously expanding volume of air pushing cohesive slugs of material along the pipe. This system uses a transfer vessel / pump tank to feed the material into the conveying line. It is a batch system with plugs of material separated by cushions of air. The velocity range at the source can be as low as 200 fpm but rarely exceeds 2000 fpm. Dense phase technology reduces the air consumption to the absolute minimum by allowing the system to convey at maximum density. Dense phase conveying is mainly used for high capacity and long distance conveying." "Lean Phase (Dilute Phase) Pneumatic Conveying system : The main principle of a Dilute Phase conveying system / Lean Phase Pneumatic conveying system is to use a relatively large amount of air to convey a relatively small amount of material and at lower pressures than dense phase systems. The material is transported at high velocities through the system while being suspended in air. It is often referred to as suspension flow because the particles are held in suspension in the air as they are blown or sucked through the pipeline. To keep the material in suspension, it is necessary to maintain a minimum conveying air velocity. There is virtually no limit to the range of materials that can be conveyed with dilute - phase system. Products commonly conveyed in dilute phase systems include cement, fly ash, fine particles, flour, resins, specialty chemicals, ground feeds, and granular and palletized products. A dilute phase system will generally be lowest in capital cost but slightly costlier with operating cost compared to Dense phase conveying system which is exactly vice versa. This system also can run on both positive (pressurised) / negitave (vacuum) technique. ance conveying." "Combined Lean phase and dense phase pneumatic conveying system This system uses both - Combination of Negative - Positive Pressure i.e. pull-push system which has the advantages and benefits of both negative and positive pressure arrangements in a single system. These systems are used where there are multiple material entry points, and multiple delivery points. A very common application is the unloading of a standard railcar. This system of conveying is given only on specific customer demands."

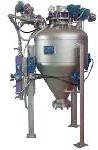

Dense Phase Conveying System

Get Price Quote

We are one of the renowned Manufacturers, Exporters, and Suppliers of Dense Phase Conveying System from India. Our Dense Phase Conveying System is widely demand in various industries due to its excellent performance and durability. Our Dense Phase Pneumatic Conveying Systems employs small amounts of high-pressure low-velocity gas to smoothly transit slugs of dry powdered or granular materials in controlled amount through enclosed convey lines. The System reduces the tear and wear of components like abrasive, fragile, friable, or mixed-batch materials. Features : Effective performanceLong operational lifeHigh strength Great resistance to weathering Handles varied kind of materials Affordable prices Advantages : Gently handles material Reduces product degradation Minimize component wear Reduces dusting Flexible routing

Air Slide Conveyor

Get Price Quote

We offer Air Slide Conveyors which are extensively used in for material handling. Air slide conveyors efficiently combine low air pressure and gravity to fluidize and convey most types of fine dry granular materials.

Pneumatic Powder Conveying Systems

Get Price Quote

We provide Pneumatic Conveying System for conveying Powder, Granuels, etc. Our Pneumatic Conveying System is available in food grade stainless steel version, Mild Steel version and also In F.R.P. Material Version. We supply Pneumatic Conveying System as per customer requirements. We manufacturer of Pneumatic Powder Conveying Systems for MCCP Powder, Zinc Sulphate Powder, Lime Powder, Wheat and Rice Flour, etc Features : • Easy to Operate • Increase the Production • Reduce Manpower • Hygienic • Reduce the wastage This is the process of conveying /transporting bulk material through a pipe line by either negative or positive pressure air system. The air , when moving with specific velocity, will carry material comes in its path. This system are designed by vast experience, rather than just by formula. Hindustan offers specialize designed system which offers considerable economy. BASIC COMPONENTS : Blower/ Fan Rotary feeders Loadings Tees Diverter valves Dust separators (optional) Control systems

Vacuum Conveying System

Get Price Quote

Pneumatic Conveyor System

Get Price Quote

With the assistance of our capacious warehouse, we are able to meet the bulk as well as urgent requirements of the buyers. Our unit is supervised by the experts ensuring complete safety of the lot. Raw materials used in the production of our entire range are sourced from the reliable providers present in the market. Due to this, we guarantee quality products at buyer's end.

Air Quenching Honeycomb Belt Conveyor

Get Price Quote

With thorough knowledge of the industry, we are engaged in providing Air Quenching Honeycomb Belt Conveyor. Manufactured by stainless steel strips formed in peculiar shape and reinforced with stainless steel round bars, the Air Quenching Honeycomb Belt Conveyor comply with industry set standards. Rigorously examined on different parameters of quality before the final dispatch, the Air Quenching Honeycomb Belt Conveyor is available in various specifications, to suit the needs of the patrons. Attributes of Air Quenching Honeycomb Belt Conveyor Enhanced load bearing capacity Medium to light forgings can be handled on these conveyors Slow moving conveyors Variable frequency drive (VFD)

Pneumatic Conveying System

300,000 Per Piece

1 Piece (MOQ)

Pneumatic Conveyor

Get Price Quote

Bulk material movement made easy Pneumatic conveyors use air as a force to transfer the material. The quantum of force to be applied depends on the product and its properties. Since hot or cold air can be used in the pneumatic conveyors, additional drying or cooling effect can be provided. SAKA’s pneumatic conveyors can be used with spray dryers and best result can be achieved if ambient air is used giving dual effect of conveying as well as cooling the material.

aero mechanical conveyor

Get Price Quote

aero mechanical conveyor, Pressure Vessel, Screw Conveyor, Pressure Vessels

dense phase pneumatic conveying systems

Get Price Quote

dense phase pneumatic conveying systems, chemical diverter valves

Pneumatic Conveying System

Get Price Quote

Pneumatic Conveying System, Screw Conveyors, blenders, Roller Conveyors

Pneumatic Conveying System

Get Price Quote

Pneumatic Conveying System, Ceramic Lined Pipes, ash handling equipment

Servo-pneumatic positioning systems

Get Price Quote

Servo-pneumatic positioning systems, Sensors, Image Processing Systems

Air Quenching Honeycomb Belt Conveyor

Get Price Quote

Air Quenching Honeycomb Belt Conveyor, Die Lubrication Spraying Unit

food industry

Get Price Quote

food industry, Diesel Genset, Fertilizer, Gas Genset, glass

Pneumatic Conveying System

Get Price Quote

Pneumatic Conveying System, distillery plant, Spray Dryer

Pneumatic Conveying System

Get Price Quote

Pneumatic Conveying System, Air Pollution Control Equipment, Spray Cooler

Pneumatic Pick and Place

Get Price Quote

Pneumatic Pick and Place, Analog Frequency Controller

Pneumatic Conveyors

Get Price Quote

Pneumatic Conveyors, Site Fabrication Services