Pneumatic Conveying System

Get Price Quote

Dense Phase Pneumatic Conveying is suitable for transporting difficult, abrasive or friable materials and pushes material along a pipe in a plug form at relatively low velocities. This means minimal wear on pipes / bends, promoting minimum maintenance and long life. Efficient use of compressed air also gives low power consumption and operating costs. Schenck Process is regarded as one of the world’s leading Dense Phase Pneumatic Conveying providers. Schenck Process’s range of Dense Phase Pneumatic Conveying Systems capitalise on all the assets of Pneumatic Conveying: Simplicity, Reliability and Flexibility. Designed to be a simple and effective method of transferring material from single collection point to either a single or multiple reception points and can be used throughout many industries to transfer all types of bulk solid materials ranging from fine cohesive powders to wet lump coal. Systems are available for handling material temperatures up to 450 degrees Centigrade and at rates of up to 100 tonnes / hour for distances up to 200 metres. To provide the most effective system solution requires a range of pumps and pressure vessels depending upon the material and distances to be conveyed.

Vacuum Conveying System

125,000 Per Piece

1 Piece (MOQ)

Best Deals from Pneumatic Conveyors

Vacuum Conveying System

Get Price Quote

Pneumatic Conveying System

300,000 Per Piece

1 Piece (MOQ)

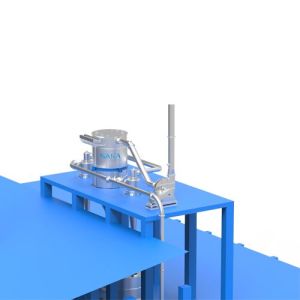

Pneumatic Conveyor

Get Price Quote

Bulk material movement made easy Pneumatic conveyors use air as a force to transfer the material. The quantum of force to be applied depends on the product and its properties. Since hot or cold air can be used in the pneumatic conveyors, additional drying or cooling effect can be provided. SAKA’s pneumatic conveyors can be used with spray dryers and best result can be achieved if ambient air is used giving dual effect of conveying as well as cooling the material.

Air Quenching Honeycomb Belt Conveyor

Get Price Quote

With thorough knowledge of the industry, we are engaged in providing Air Quenching Honeycomb Belt Conveyor. Manufactured by stainless steel strips formed in peculiar shape and reinforced with stainless steel round bars, the Air Quenching Honeycomb Belt Conveyor comply with industry set standards. Rigorously examined on different parameters of quality before the final dispatch, the Air Quenching Honeycomb Belt Conveyor is available in various specifications, to suit the needs of the patrons. Attributes of Air Quenching Honeycomb Belt Conveyor Enhanced load bearing capacity Medium to light forgings can be handled on these conveyors Slow moving conveyors Variable frequency drive (VFD)

aero mechanical conveyor

Get Price Quote

aero mechanical conveyor, fermenters, deaeretor spray nozzle, bleaching tube

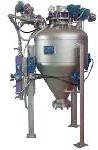

dense phase pneumatic conveying systems

Get Price Quote

dense phase pneumatic conveying systems, chemical diverter valves

Pneumatic Conveying System

Get Price Quote

blenders, Roller Conveyors, Industrial Boiler, industrial vessels

Pneumatic Pick and Place

Get Price Quote

Pneumatic Pick and Place, Analog Frequency Controller

food industry

Get Price Quote

food industry, Diesel Genset, Gas Genset, glass

Air Quenching Honeycomb Belt Conveyor

Get Price Quote

Air Quenching Honeycomb Belt Conveyor, Die Lubrication Spraying Unit

Pneumatic Conveying System

Get Price Quote

distillery plant, Spray Dryer, Fluidised Bed Dryers, Industrial Condensers

Pneumatic Conveying System

Get Price Quote

Ceramic Lined Pipes, ash handling equipment

Pneumatic Conveying System

Get Price Quote

Spray Cooler, Rotary Air Valves, Flash Dryer, Dust Extraction System

Pneumatic System

Get Price Quote

Floor Wiper Rubber, restaurant cart

Pneumatic Conveyors

Get Price Quote

Pneumatic Conveyors, Site Fabrication Services

Servo-pneumatic positioning systems

Get Price Quote

Servo-pneumatic positioning systems, Sensors, Image Processing Systems