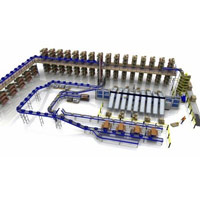

Powder conveying system

Get Price Quote

1 Piece (MOQ)

Pneumatic Kick Out System

675,000 - 780,000 Per Piece

1 Piece (MOQ)

Best Deals from Pneumatic Conveyors

vacuum transfer system

150,000 - 300,000 Per Uni

150000 Unit (MOQ)

Vacuum Transfer System occurs when a material is conveyed in suspension in the flowing air.Advantages-- Low Air Consumption- Little or no degradation of fragile material- Optimum solids to Air Ratio & Conveying Velocity- No Spillage, dust free & no hygiene problems during product handling

Vacuum Conveying System

125,000 Per Piece

1 Piece (MOQ)

Pneumatic grain conveyors

150,000 - 150,000 Per Unit

1 Unit (MOQ)

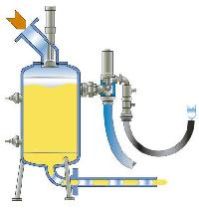

Dense Phase System

Get Price Quote

In a typical Dense Phase System a relatively high pressure is utilized (above 15 psig), to transfer powder or granular bulk solids through a pipeline with a low velocity (CFM) air. In the whole working cycle of Dense Phase System the transport vessel fills with gravity and when the transport er gets full, the inlet & vent valve become close which lead system to get pressurized. This resulted in the material flow into conveying line and at the end to the destination. And we are the only one who manufactures especially developed dense phase system, having required characteristic, highly demanded by today's industrial sector. We provide dense phase pressure system of various specifications at a cost effective prices. As a primary manufacturer of high end engineering products, we have made distinctions among the famous dense phase conveying system manufacturers.

Big Bag Unloading Pneumatic Conveying System

50,000 Per Piece

1 Piece (MOQ)

Industrial Pneumatic Conveyors

Get Price Quote

Pneumatic Conveying Systems

Get Price Quote

We are engaged in manufacturing, supplying and exporting Pneumatic Conveyor Systems. These systems are manufactured using high grade raw material. Moreover, our experience has given us knowledge in conveying different kind of materials and also designing custom built equipments. Pneumatic conveyor system is method of conveying powdered material such as powder & granules of size from few microns to 25 mm. PES offers Dilute phase conveying systems. Dilute phase conveying system uses low pressure air at pressure less than 1 bar in case of pressure conveying and 5000 mm in case of vacuum conveying which is generated by positive displacement type roots blower or by centrifugal blower. Furthermore, we offer these conveying systems at market leading prices. Application: Cement, Bleaching earth, Powder, Grains, Fly ash,Gypsum and many more. 1. VACUUM CONCEPT CONVEYING SYSTEM The Vacuum Concept Conveying System is a dilute phase, medium to high velocity, low pressure, continuous vacuum conveying system for shorter distances. It is generally used to convey low to high density, non-abrasive and semi-abrasive materials. Examples include Bleaching Earth, sugar, ironoxide, titanium dioxide, silica flour, cement, and limestone. The material is fed into the conveying line on a continuous basis by vacuum. Air Saver technology is used to minimize and optimize the low pressure supply air which is supplied by a low pressure positive displacement blower. The system includes a vacuum pickup nozzle, a vacuum filter receiver, a rotary airlock feeder and a positive displacement blower. 2. PRESSURE CONCEPT CONVEYING SYSTEM The Pressure Concept Conveying System is a dilute phase, low pressure, high velocity, continuous conveying system. It is generally used for conveying low to medium density, and non-abrasive bulk solids where degradation of the conveyed material is not a concern. Examples of materials include flour, sugar,salt, grain, malt and plastic pellets. This concept utilizes a rotary airlock feeder to control the feed rate into the conveying line. A low pressure positive displacement blower is used for the air supply.

Air Slide Conveyor

Get Price Quote

We offer Air Slide Conveyors which are extensively used in for material handling. Air slide conveyors efficiently combine low air pressure and gravity to fluidize and convey most types of fine dry granular materials.

Pneumatics Hydraulics system

Get Price Quote

DeGATECH in collaboration with Adroit group, has ventured in the field of Pneumatic & Hydraulic products. This vertical is handled by its experienced and dedicated employees who have been catering to Indian Industry since almost 3 decades. Company manufactures Hydro-pneumatic Equipments, Large Bore Double Acting Pneumatic Cylinders, Hydraulic Automation Systems, Hydraulic Equipments, Pneumatic Equipments, Hydraulic Valves, Pneumatic Actuators, Pneumatic Automation Systems, Pneumatic Valves, Power Pack Unit, Pressure Switches, Rotary Actuators, Control Valves, Feed Control Cylinders.

Vacuum Conveying System

Get Price Quote

Pneumatic Conveying System

Get Price Quote

Pneumatic conveying systems are basically quite simple and are eminently suitable for the transport of powdered and granular materials in factory, site and plant situations.

Pneumatic Conveyor

Get Price Quote

The company is deep rooted in Maharashtra(India) and has gained a distinguished position in the market. We follow stringent quality measures to ensuring the product quality so as to attain maximum client satisfaction.

Vacuum Conveying System

225,000 Per Piece

01 Piece (MOQ)

Pneumatic Conveying System

Get Price Quote

Lean Phase Pneumatic Conveying system, Dense Phase Pneumatic Conveying system Plutontek, Designs & Manufactures, pneumatic conveying systems as a tailor made product, to provide solutions for bulk material handling. Design of system depends on the product characteristics, particle size, capacity, number of inlet sources and number of outlet / destinations, etc. Each pneumatic conveying system needs to be designed & customized as per the application given. Prime mover for conveying the product can be Roots blower, Compressor, Centrifugal blower, Centrifugal fan or Radial blower, depending upon bulk density of the material to carry, Length of the system, flow rate required and pressure required at outlet. System can run on both negative / positive pressure, depending upon the situation. At Plutontek, we have to consider all the given parameters to design the system and has to offer the optimum solution to customer in order to achieve economies in intial cost as well as running cost You can rely on us for all your customized requirements of : Dense Phase Pneumatic Conveying systems Lean Phase Pneumatic Conveying systems / Dilute Phase Pneumatic Conveying systems Combined Lean Phase and Dense Phase Pneumatic Conveying systems "Dense Phase Pneumatic Conveying system : The main principle of a dense phase conveying system is to slow down the velocity of the product in the pipe conveyor to a point that is below the speed at which the product breaks or degrades. At low velocities, the product lies for periods of time in the bottom of a horizontal line and it is blown under pressure to the discharge point in slugs or plugs. The dense phase pneumatic conveying systems uses low volume, medium pressure air stream and relies on a continuously expanding volume of air pushing cohesive slugs of material along the pipe. This system uses a transfer vessel / pump tank to feed the material into the conveying line. It is a batch system with plugs of material separated by cushions of air. The velocity range at the source can be as low as 200 fpm but rarely exceeds 2000 fpm. Dense phase technology reduces the air consumption to the absolute minimum by allowing the system to convey at maximum density. Dense phase conveying is mainly used for high capacity and long distance conveying." "Lean Phase (Dilute Phase) Pneumatic Conveying system : The main principle of a Dilute Phase conveying system / Lean Phase Pneumatic conveying system is to use a relatively large amount of air to convey a relatively small amount of material and at lower pressures than dense phase systems. The material is transported at high velocities through the system while being suspended in air. It is often referred to as suspension flow because the particles are held in suspension in the air as they are blown or sucked through the pipeline. To keep the material in suspension, it is necessary to maintain a minimum conveying air velocity. There is virtually no limit to the range of materials that can be conveyed with dilute - phase system. Products commonly conveyed in dilute phase systems include cement, fly ash, fine particles, flour, resins, specialty chemicals, ground feeds, and granular and palletized products. A dilute phase system will generally be lowest in capital cost but slightly costlier with operating cost compared to Dense phase conveying system which is exactly vice versa. This system also can run on both positive (pressurised) / negitave (vacuum) technique. ance conveying." "Combined Lean phase and dense phase pneumatic conveying system This system uses both - Combination of Negative - Positive Pressure i.e. pull-push system which has the advantages and benefits of both negative and positive pressure arrangements in a single system. These systems are used where there are multiple material entry points, and multiple delivery points. A very common application is the unloading of a standard railcar. This system of conveying is given only on specific customer demands."

Pneumatic Conveying System

Get Price Quote

Dense Phase Pneumatic Conveying is suitable for transporting difficult, abrasive or friable materials and pushes material along a pipe in a plug form at relatively low velocities. This means minimal wear on pipes / bends, promoting minimum maintenance and long life. Efficient use of compressed air also gives low power consumption and operating costs. Schenck Process is regarded as one of the world’s leading Dense Phase Pneumatic Conveying providers. Schenck Process’s range of Dense Phase Pneumatic Conveying Systems capitalise on all the assets of Pneumatic Conveying: Simplicity, Reliability and Flexibility. Designed to be a simple and effective method of transferring material from single collection point to either a single or multiple reception points and can be used throughout many industries to transfer all types of bulk solid materials ranging from fine cohesive powders to wet lump coal. Systems are available for handling material temperatures up to 450 degrees Centigrade and at rates of up to 100 tonnes / hour for distances up to 200 metres. To provide the most effective system solution requires a range of pumps and pressure vessels depending upon the material and distances to be conveyed.

Pneumatic Conveying System

300,000 Per Piece

1 Piece (MOQ)

Vacuum Conveying System

Get Price Quote

Vacuum conveying system Materials of construction are selected to suit the application (MS SS304 SS316), Screw Conveyors are usually designed to suit specific applications as per Customer Requirement.

Pneumatic and Pneumoelectronic Maultigauging System

Get Price Quote

FOR CONNECTING RODS Big, Twist, CD Big End DIA and Small End DIA Squareness with respect to Face FOR CRANK SHAFT Pin Hole Dia, Shaft Dia, Center Distance between Hole and Shaft FOR CYLINDER BLOCK/LONG LENGTH COMP. Dia at multilevel, taper and oval Sqaureness FOR GEAR BLANK ID,OD,Concentrity, Face Parellelism, Depth Sqaureness SPECIAL TAPER AND ANGLE CHECKING SYSTEMS All Pneumatic and Electronic Systems can be connect with PC for SPC

Pneumatic Conveying System

225,000 Per Piece

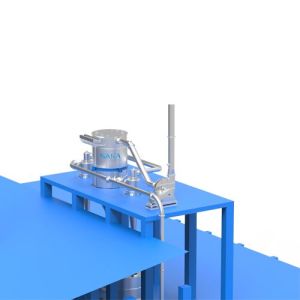

Pneumatic Conveyor

Get Price Quote

Bulk material movement made easy Pneumatic conveyors use air as a force to transfer the material. The quantum of force to be applied depends on the product and its properties. Since hot or cold air can be used in the pneumatic conveyors, additional drying or cooling effect can be provided. SAKA’s pneumatic conveyors can be used with spray dryers and best result can be achieved if ambient air is used giving dual effect of conveying as well as cooling the material.

Pneumatic Automation System

Get Price Quote

For several decades Schrader has been engaged in offering Pneumatic systems for a wide section of the Industry. Equipped with a highly qualified and experienced team and computer aided design tools, we undertake to provide automation solutions from design to execution.

Pneumatic Conveyors

Get Price Quote

Pneumatic conveying is one of the most popular method of moving flake ice in chemical & construction industry for following reasons,Multipoint delivery is possible, when ice use points are located on different floors.Ice use points are not in -line & located in zigzag manner.

Pneumatic Automation System

Get Price Quote

For several decades Schrader has been engaged in offering Pneumatic systems for a wide section of the Industry. Equipped with a highly qualified and experienced team and computer aided design tools, we undertake to provide automation solutions from design to execution.

Pneumatic Conveying System

Get Price Quote

The pneumatic conveying is necessarily custom made conveying system & based on product characteristics, particle size, throughput capacity, number of sources and number of destinations. Dilute phase is a suspension flow wherein the material to be conveyed is introduced into a moving air stream inside a pipeline. FEATURES The dilute phase conveying system uses low-pressure air at pressures less than one bar in case of pressure conveying and (-) 5000 mm in case of vacuum convening, which is generated by positive displacement type roots blowers or by centrifugal blowers For the material to remain in suspension there is a minimum conveying velocity which varies for different materials. The quantity of material that is fed into an air stream is also dependent on material characteristics like bulk density, particle size, sieve analysis, frequency distribution etc Generally, the material to air ratio varies between 3 to 10 kg of material to kg. of air Conveying velocities are in the range of 18 to 28 m/sec depending on the product characteristics

Pneumatic Conveyor System

Get Price Quote

With the assistance of our capacious warehouse, we are able to meet the bulk as well as urgent requirements of the buyers. Our unit is supervised by the experts ensuring complete safety of the lot. Raw materials used in the production of our entire range are sourced from the reliable providers present in the market. Due to this, we guarantee quality products at buyer's end.

hydro pneumatic systems

Get Price Quote

We are in to manufacturing of HYPN since 1994. More than 1000 installations are the testimony of our expertise and quality of manufacturing. We offer the following products and services. HYPNS with 1 to six pumps running in parallel Pumps in parallel and in series for high head application, with out break tank Pressure switch/VFD controlled systems Bladder vessel in pump room or at top level in the zone. PUMPS :We offer following types of pumps depending upon clients requirement/suitability at site Vertical in line st. steel (AISI 304) Type- HYDRO BOOST-R Mono submersible pumps for low and medium head application-HYDRO BOOST-SM MONO BLOCK pumps for low and medium head ,economical duties- Type HYDRO BOOST-M Submersible pumps in casing pipe, Type- HYDRO BOOST SC VERT/HORIZONTAL Submersible Pumps-HYDRO BOOST-S HYPN System DESIGN :We offer the systems as per consultant’s client’s design. We also provide free design service upon getting full information from the client CONSTRUCTION :HYPN Systems are packaged units consisting, pumps, piping, bladder vessel, control panel duly piped and wired. All components are mounted on Base frame. At site it is only required to give suction and delivery connection, and one electrical connection. In some cases components are sent separately to avoid bulky packaging. These are assembled at site RANGE :The HYPNS are offered in wide range of duties, without any limit for Discharge and Head. HYPNS suitable for working efficiently in wide range of capacities. Low demands are met by Bladder vessels.The HYPNS can be offered in material of construction as per requirement. APPLICATIONS : As a domestic and flushing water supply, Hot water supply units in Multistoried buildings, Colonies, Industry etc As a water supply unit for curing water to cement plastered walls and ceilings

pneumatic control systems

Get Price Quote

We are the leading manufacturers, exporters and supplier of this products.

Air Quenching Honeycomb Belt Conveyor

Get Price Quote

With thorough knowledge of the industry, we are engaged in providing Air Quenching Honeycomb Belt Conveyor. Manufactured by stainless steel strips formed in peculiar shape and reinforced with stainless steel round bars, the Air Quenching Honeycomb Belt Conveyor comply with industry set standards. Rigorously examined on different parameters of quality before the final dispatch, the Air Quenching Honeycomb Belt Conveyor is available in various specifications, to suit the needs of the patrons. Attributes of Air Quenching Honeycomb Belt Conveyor Enhanced load bearing capacity Medium to light forgings can be handled on these conveyors Slow moving conveyors Variable frequency drive (VFD)