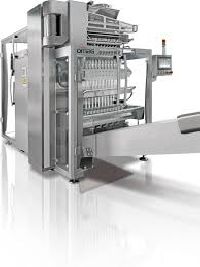

Stick Pack Machine

Get Price Quote

Stickpack does not only mean cost saving. Apart from saving in packaging and space in the warehouse and production plant, stickpack technology helps in following the current market trends of the single dose packaging.Stick packs are extremely convenient to consume, easy to carry, and are ideal for sampling. ARANOW Packaging Machinery is a top manufacturer of multilane packaging machinery for packing stick packs.To complement these machines, Aranow also offers a world-class range of secondary packaging machines. ACG Value Links, a member of ACG Worldwide, is proud to bring such advanced packaging technologies for Indian chemical & cosmetics, food & beverages, pharmaceutical and dairy industries.

Peanut Shelling Machine

Get Price Quote

Peanut Shelling Machine is produced according to the national standards strictly. It consists of rasp bar, stake, intaglio, fan, gravity separator and second bucket, etc. The whole machine frame is made of high-quality steel and the shelling chamber is made of stainless steel. This peanut shelling machine has compact structure, easy operation and reliable performance. It is used to shell peanut; can separate shells and kernels with high-efficiency and almost without damage to the kernel; and the shelling rate can be ≥95%, the breaking rate is≤5%. While peanut kernels are used for food or the raw material for the oil mill, the shell could be used to make wood pellets or charcoal briquettes for fuel. Technical Parameter: Model PVGAMS-400 PVGAMS-800 PVGAMS-1500 PVGAMS-1600 PVGAMS-3000 PVGAMS-3300 Capacity(kgh) 400 800 1500 1600 3000 3300 Power(kw) 2.2 4 5.5 7.5 11 11-15 Shelling rate ≥95% ≥95% ≥95% ≥95% ≥95% ≥95% Breaking rate ≤5% ≤5% ≤5% ≤5% ≤5% ≤5% Losing rate ≤0.5% ≤0.5% ≤0.5% ≤0.5% ≤0.5% ≤0.5% Cleaning rate ≥95.5% ≥95.5% ≥95.5% ≥95.5% ≥95.5% ≥95.5% Weight(kg) 137 385 775 760 960 1315

Best Deals from Pouch Packaging Machines

rice packaging machine

Get Price Quote

rice packaging machine, Case Packer

blister packaging machines

Get Price Quote

blister packaging machines, dynamic checkweighers, cartoners

blister packing machines

Get Price Quote

blister packing machines

Blister Packing Machine

Get Price Quote

Blister Packing Machine, Cartoning Machine, integrated line machine