Grinding Projectile

Get Price Quote

Made of medium-hard, flexible polyurethane with a rugged surface. The projectile can be reused. Always clean the tube with our EC Flexible projectile after using the grinding-projectile. Withstands 5% compression.

Precision Turned Component

Get Price Quote

We are offering precision turned component.

Best Deals from Precision Turned Components

Brass Precision Turned Components

Get Price Quote

Owing to the wide experience in this domain, we are instrumental in offering Brass Precision Turned Component to our clients. We manufacture Customised Brass Precision Turned Components.

Precision Auto Turned Components

Get Price Quote

We have requisite facilities to provide our clients with Precision Auto Turned Components. Our entire product line of Precision Auto Turned Components is manufactured using quality tested ferrous metal and single spindle auto-mats. These Precision Auto Turned Components are available in diameters ranging between 1 mm and 32 mm. Furthermore, our technical expertise has helped us in manufacturing Precision Auto Turned Components in customized designs to fit the exact needs of our customers. Features : Resistance to corrosion Longer functional life Lightweight

Cnc Precision Turned Components

100 - 200 Per Piece

10 Piece (MOQ)

precision auto turned parts

Get Price Quote

High precision engine, electrical connectors,high pressure hydraulic fittings,engine valve collets,rockerarm screw socket assy.

Precision Turned Components

Get Price Quote

Perfect Technologies are engaged in manufacturing of Precision Turned Components in Ferrous material for various sectors like Automotive,Non-Automotive and Aerospace Etc.

Precision Turned Components

500 Per Piece

Cnc Precision Turned Components

400 Per Piece

Use of finest raw material helps us in bringing forth exceptional products. Due to this very fact, we make use of only quality raw materials procured from trusted sources. Courtesy years of experience, our company has emerged as leading suppliers of CNC Precision Components. Features : Sturdy Durable Reliable Excellent quality Contemporary designs

Precision Turned Components

Get Price Quote

We manufacture precision machined components as per customer's drawing.

precision cnc turned parts

Get Price Quote

The offered assortment of quality products is a result of complete quality inspections done at varied stages of sourcing raw material, which plays a vital role in delivering the finest products. Our entire range of products is produced as per international quality standards. Therefore, they are dependable and worth the price.

Cnc Precision Turned Components

300 - 500 Per Per hour

1 Hour (MOQ)

Precision Turned Components

Get Price Quote

We are offering precision turned components. We are amongst the leading company involved in manufacturing and supplying a wide range of precision turned components. detailed description these are manufactured using high grade material and sophisticated technology that ensures its high durability. Offered products are available in different sizes and have sturdy construction. These are perfectly finished and are reliable in nature. Moreover, we assure safe and timely delivery of our products. features: long life resistant to corrosion affordable prices.

cnc precision turned component

Get Price Quote

Precision Turned Grinding Component

15 Per Piece

We are the leading manufacturers, exporters and supplier of this products.

Precision Turned Components

Get Price Quote

Ours firm is recognized as the reputed Manufacturer and Supplier of highly efficient Precision Turned Components. Our wide array of Precision Turned Components is manufactured using high-grade materials and appreciated for high strength, precision design, corrosion resistance and longer functional life. We provide Precision Turned Components in different sizes to meet the requirements of the clients.

Precision Turned Parts

Get Price Quote

We offer you precision turned parts according customer drawings for all kind of branches manufactured from all free-cutting metals in the dimensional range of 4 - 95mm. You too can benefit from our knowhow. From some of the most modern manufacturing technology, highest precision and value for money. We dedicate our efforts to your success

Precision Turned Component

8 - 10 Per Piece

Precision Cnc Turned Components for Automobile

Get Price Quote

Manufacturers of Quality Precision Turned Components to Customer Design and Production Needs. Latest Cnc Sliding Head Lathes with Capacity Up to 32mm to Capacity Up to 42mm. Iso 9001: 2000 Registered and Suppliers to Aerospace, Defence, Medical and Commercial Sectors. other Services Provided Include; In-house Zone Annealing Along with Finishes and Plating By Preferred Suppliers. Assembly and Sub-assembly Work Undertaken. Small to Medium Batch Runs for Jit Delivery. Competitive Quotations and Lead Times.

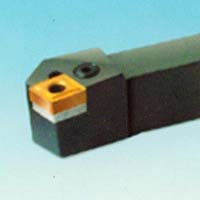

Hard part turning

Get Price Quote

Turning steel with a hardness over 45 HRc (typically within the range of 55-68 HRc) is defined as hard part turning and is a cost efficient alternative to grinding. Hard part turning has been proven to reduce machining time and costs by 70% or more, and also offers improved flexibility, better lead times and higher quality.