Tubular Pressure Part

Get Price Quote

Our investment in the well-structured warehouse has paid off well. We have successfully installed up-to-the-minute warehouse management software to keep the entire lot in a safe and organized manner. Located in Pune(India), we are a reliable entity when it comes to quality centralized and cost effective products.

Boiler Pressure Parts

Get Price Quote

Delivering the orders on time is one of our specialties for which we are highly admired by the clients. We are a quality centric organization, offering the best-in-class products that are manufactured using the experts approved and certified raw material procured from reliable sources.

Best Deals from Pressure Parts

Pressure Parts

Get Price Quote

We are dedicatedly engaged in manufacturing and supplying quality-approvedBoiler Parts. Designed at par with international quality standards, all our products are manufactured using high-grade material and quality components that are sourced from the trusted vendors of the market. Also, these products are checked by expert quality controllers on various parameters to ensure flawlessness.

Pressure Parts

Get Price Quote

We offer our client's qualitative range of pressure parts manufactured using high grade raw material. Our range is available in various specifications and dimensions and can also be customized as per the replica watches client's requirement at industry leading prices. Its features are given below:: 1. High performance 2. Durable 3. Corrosion resistant

boiler pressure part

Get Price Quote

We are designers, manufacturers and erectors of Boiler Pressure Parts. Boilers: from 05 kgcm ² pressure to 125kgcm² and from 0.5 kg to 150 TonsHr Capacity.

aluminium pressure die casting part

Get Price Quote

Boilers And Pressure Parts

Get Price Quote

Oil/Gas Fired, 3 Pass, Water Tube Coil Type Steam Boiler. The SU series is a reverse flue, three pass, water tube design steam boiler. Itgives quick steam output within 4 minutes from cold start. The combustion chamber and the smoke passages are accurately designed, which ensures that combustion occurs perfectly. It does not require any qualified boiler attendant. It is ideal for small and medium sized plants, where average steam pressure (10 Bar) is required. Units can also be designed for higher pressures.Salient Features of the SU - Oil/Gas Fired, 3 Pass, Water Tube Coil Type Steam Boilers are Reverse flue design Single coil for easy maintenance Larger pipe diameters Improved efficiency Instant steam generation The SU series is also available in horizontal designs, with options of imported burners. Complete skid mounted units can also be offered. The feed water tank, water softener and fuel tank are mounted on one skid.Units are manufactured in non-1BR designs upto 850 kgs/hr and in IBR certified models of 1000 kgs/hr and above. We also offer coil type steam boilers up to capacities of 3TPH with Solid Fuel,Oil/Gas Fired, 3 Pass, Shell Type, Fuel Tube Steam Boiler . Steam boilers in the output range of 200 to 600 kg/hr are manufactured in tree-pass smoke-tube, dry back compact shell type configuration and designed in conformity with SIB/Class 1 IBR codes. These boilers are fitted with FD/ID combustion & hinged refractory doors for ease of operation & maintenance making them quite compact and efficient packaged machines. Salient Features of the SU - Solid Fuel, Oil/Gas Fired, 3 Pass, Shell Type, Flue Tube Steam Boilers are 3 pass compact steam boiler built as per IBR Easy to operate and maintain with low power consumption Hinged doors for quick cleaning of smoke tubes Fitted with necessary controls and safety for trouble-free operation Sufficient water/steam volume for steady steam output Solid Fuel,Oil/Gas Fired, 3 Pass, Shell Type, Fuel Tube Steam Boiler. Shell Type Flue Tube Steam Boiler is a horizontal shell type integral furnace, flue tube, multi fuel fired steam boiler. Capacities available are from 500Kgs/hrupto 3 Tonnes/hr steam in single furnace design and upto 6 Tonnes/hr steam in double furnace design. Units are designed as per Indian Boiler Regulations. It can be used on various fuels such as coal, lignite, Oil/Gas, wood & bagasse pellets. Fluidized bed combustion system is supplied to burn fuels such as rice husk and saw dust.An induced draft fan is provided for proper combustion and balanced draft in the combustion chamber.High Thermal efficiency is achieved by using a large furnace, an efficient burning system and correct heat release rate between radiant and convective sections.Boilers are designed to ensure uniform distribution of thermal and mechanical stresses in heat transfer surfaces.Salient Features of the SU - Multi Fuel Fired, 3 Pass, Shell Type, Flue Tube Steam Boilers are Minimum space required due to compact design Fast start-up, erection & commissioning Very easy to operate & maintain Low power consumption Hinged doors for easy inspection & maintenance of boiler Smoke Cum Water Tube External Furnace Steam Boiler. The SU series combines the benefits of a watertube furnace along with a multipassfiretube steaming chamber. This results into higher heat transfer area , hence increasing efficiency as compared to conventional solid fuel fired steam boilers. High efficiency is achieved by properly utilizing the fuels radiant heat in the water cooled furnace and the shell type steaming chamber.The SU series units are built in accordance with the stringent Indian Boiler Regulations. Each unit is independently tested and inspected by the boiler inspector in various stages, which ensures a good quality product. Various fuels can be burnt in the SU series units, like coal, wood agrowaste, rice husk & saw dust. It can also be used to fire various gaseous and liquid fuels.It is ideally used where steam is required at high pressures. It can be coupled to a steam turbine to generate power.Salient Features of the SU - Smoke Cum Water Tube External Furnace Steam Boilers are Reliable & robust construction Large furnace volume for high combustion efficiency Low heat release rates Available with manual as well as automatic firing options for various fuels Easy to operate and maintain Applications Agro Industries Chemical & Petrochemical Industry Food & Beverages Laundry & Dry Cleaning Textile Concrete Blocks Curing Dairy Drugs & Pharmaceuticals Batteries Coir Engineering Educational Institutes Electric Cables Hotels, Hospitals Leather Paper/ Packaging/ Plywood/ Thermocole Research & Development Tea/ Tobacco/ Timber/ Wood/ Toys/ Wool/ Silk

boiler pressure part

Get Price Quote

Supply of material, On-site Fabrication, Erection & Testing in service specific materials like MSGISMLSCSSSAlloy SteelsCIHDPEPPPVC & High pressure and temperature ratings of utility piping system as; High Pressure Steam & Condensate Thermic Fluid Compressed – Air Oxygen Nitrogen Fuel Gas – LPGLNGCNG Fuel Oil – FOLDOHSD Water – ChilledCoolingRawSoftRODM Fuel Gas Ducting Thermal & Acoustic Insulation

Pressure Die Casting Parts

Get Price Quote

plastic die mould, metallic patterns, Gravity Castings Component

Pressure Parts

Get Price Quote

For the complete range of Pressure Parts, just avail our highly acclaimed service. We present array of Boiler Pressure Parts. Our wide range of Pressure Vessel Parts is manufactured from the quality raw materials making it durable and high on performance. The most important feature of our pressure parts is that they require barest minimum maintenance. They multiply the efficiency of the pressure vessels manifold. In addition to this, we are reckoned as one of the renowned Pressure Parts Exporters and Suppliers in the market.

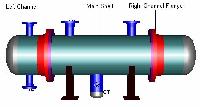

Heat Exchanger pressure vessel Parts

Get Price Quote

Heat Exchanger pressure vessel Parts, Food sector Stainless Steel Fabricators

Boiler Pressure Parts

Get Price Quote

Boiler Pressure Parts

Ibr pressure parts

Get Price Quote

Ibr pressure parts, industrial vessel, Frp Pressure Vessel

Boiler Pressure Parts

Get Price Quote

Boiler Pressure Parts, steam pipe fabrication service

pressure part

Get Price Quote

pressure part, combustion air duct, Damper, Foundation Bolt

Aluminium pressure die casting parts, aluminium gravity die

Get Price Quote

Aluminium pressure die casting parts, aluminium gravity die

Boiler Pressure Parts

Get Price Quote

Boiler Pressure Parts, process engineering

boiler pressure part

Get Price Quote

boiler pressure part, Boiler Chimney, Power And Gas Plant Equipment