Tip Dresser

Supply Diamond coated gear profile and Tip Dresser. These dresser are high quality and give long life.

...more

Profiling Threaded Grinding Wheel

Internatinal Honing Wheel

Internal hone achieve a high output of gears between re-dressings and high rate of metal removing.

...more

Internal Teeth Generator

Hard Gear Teeth Diamond Burnishing

DGB is a system to remove nicks & burr for heat-treated gears. DGB is the only system that makes economic sense. DGB cannot make a bad gear good but can make a good gear better by removing its nick & burr. COST EFFECTIVENESS DGB does not require a major capital investment. Any small gear shop with good volume can justify the cost. Even though DGB tool will last through thousands of components, the life will depends on a variable, the amount of nick and burr it has to remove. User can run 100% gears through the process and check on sampling basis. This increases master gear life, improves time and gives constant quality of gear. Comparison to Other Process Comparison to Other Process (EDM) available in market, the basic and very important advantage is that in EDM process the point where the nick burr is removed created a soft spot because the temp. at which nicks and burr are to be removed reaches to the melting temp. of steel and there is no control on the cooling process. Therefore creating soft spots which is vary dangerous for gear. The burr and nicks are identified by checking an double flank tester in close mesh with master gear. The nicks and burrs are removed by hand stoning and or by pencil grinders. This process is laborious and quality depends upon operator skill. In DGB process the orignal hardness of gear remains unchanged. Support Process for Honing Process User who hard gear hone they face a great problem with nicks and burrs as these are hard and work as crushers on the epoxy bonded abrasive wheels which loose their form. Therefore requires redressing & reducing wheel life.

...more

Gear Wheel Magnetic Encoder

Contactless & high resolution measurement High EMC & ESD stability Solid housing & complete sealing Protection class IP 68 & completely sealed Rotational direction recognition high rotational speed robust not sensitivity to dust Applications - Machine Tool Position and Speed measurement of the main spindle in lathes, grinding and milling machines Speed and position measuring in HSC Spindles (High Speed Cutting) Electronic Synchronization of helical spindles Hollow Shaft Encoder Angle measurement in radar equipment Measurement of speed and position in test stands

...more

Gear Tooth Rounding

This is an Omniversal Chamfering, Pointing, Pointing With Radius, rounding & crown chamfer for Internal & External Gear or Spline. It can even chamfer helical & straight gear & half chamfer for RH or LH Ring Gear. This Machine is a must for Production Shop Prototype gears, pre production batch and small gear shop manufacturing variety of gears and spline.

...more

Gear Teeth Honing

gear teeth

4 AXIS CNC CONTROLLER SIEMENS 802 D 810 D,Honing Wheel dia 300 mm,Max Width of Hone 50 mm,Honing Wheel Swivel ±250,Honing Head Fitted with Angular Contact Bearing,Gear Dia. Minimum 20 mm,Gear Dia. Maximum 225 mm,Module Minimum 1.5,Module Maximum 5,Distance Between Center 250-550

...more

Gear roll tester

Double Flank gear rolling test is generally included in final acceptance test. A gear tested on Double Flank Gear Tester is normally the indication of good running properties of the gear and is adequate assurance about the quality of gear. The readings taken are the validation of center distance between two gears to be inspected or between one gear and one master gear meshing without backlash during one complete rotation of gear. Adjustable center distance 50 - 248 mm Adjustable center distance with Power Drive 70 - 248 mm Adjustable measuring preasure 0.02 - 2 Kp Max. weight on Floating slide 20 Kg Max. weight on Fixed slide 40 Kg OPTIONAL STEADY ATTACHMENT Throat Depth 136 mm Max. Distance between centers 500 mm Max. Distance between centers Motorized M/c 290 mm Reading by Dial 10 micron least count Optional Dial with Power Drive 1 Micron least count Dimension Overall without steady 240W 680L 220H Overall with steady (500 between center) 240W 680L 1000H

...more

gear deburring machine

Chamfer & Deburring prevent nicks type damage during handling,Chamfer & Deburring prevent Heat Treatment Distortion,Self centering tool make equal chamfer at both end,Rolling type tool looking like a shaping Cutter gives better tool life,Tool construction compensates for width variation of face up to 0.20 mm,Automatic tool hunts if gear does not engage with tool,The machine has two slides, one horizontal slide for chamfering operation & one vertical slide for deburring operation,After setting, the cycle is automatic i.e. only loading unloading is manual,Max work dia 250 mm,Min work dia 10 mm,Max face width 105 mm

...more

Gear Chamfering and Deburring

Why Chamfering and Deburring Operation Chamfer & Deburring prevent nicks type damage during handling Chamfer & Deburring prevent Heat Treatment Distortion Features of Our Gear Chamfering & Deburring Machine Model 1060 Self centering tool make equal chamfer at both end. Rolling type tool looking like a shaping Cutter gives better tool life. Tool construction compensates for width variation of face up to 0.20 mm. Automatic tool hunts if gear does not engage with tool. The machine has two slides, one horizontal slide for chamfering operation & one vertical slide for deburring operation. After setting, the cycle is automatic i.e. only loading unloading is manual

...more

Formed Wheel Gear Grinding Machine

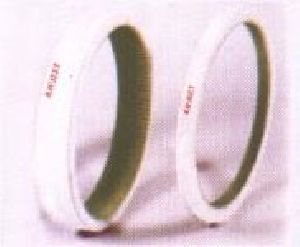

External Honing Wheel

External honing wheels have all the qualities of internal hone but are not dressable.

...more

Double Chamfering

These Cutters are very useful for lay shaft cluster gears. Two gears can be chamfered and deburred in one operation saving one loading and unloading and chamfering and deburring time.

...more

Diamond Gear Honing

4 AXIS CNC CONTROLLER SIEMENS 802 D Gear Dia. Minimum 16 mm Gear Dia. Maximum 250 mm Module Minimum 1.5 Module Maximum 5 Distance Between the center 250 - 500 Nose to Wheel Center 110 mm Till Angle ±350 X Slide Travel 200 mm Y Slide Travel 300 mm Max.Honing Length 100 mm

...more

Deburring Cutter

These Cutters work like a Rotary Shears. These are held against the sides of faces of the gear. The variation in the width of blank is taken by spring loaded blades. Deburring Cutter remove burrs neatly. These are resharpenable and give very long life.

...more

Combi Chamfering Cutter

These Cutters have alternate Chamfering and Rolling Profile teeth. This type of Cutter does not produce any secondary burr on tooth flank. These Cutters are must if gear are directly honed. Even if gear are shaved the life of shaving cutters improve between re-sharpening.

...more

Chamfering Cutter

These Cutters have teeth like Bevel Gear, Meshing with the Gear produce chamfer by Rolling Process. RAVJEET Cutters have special Strong profile. The Cutters is not Accident Prone & give long life

...more

Chamfering and Rollling Cutters

These Cutters have a Master Rolling Gear in the center of a pair of chamfering blades. These Cutters Roll the Profile and eliminates the subsequent operating such as shaving etc. on two wheeler gears.

...more

gear champings

debring gear boxes

Reduction Gears

gear cutting

gear testing

Be first to Rate

Rate ThisOpening Hours