Unmonitored Spray Nozzle

We are one of the prominent Manufacturers and Suppliers of Unmonitored Spray Nozzle. In this Spray Nozzle, lubricant is monitored through limit switch, which is attached to distributor and air is monitored through pressure switch that is installed after the last nozzle. Manufactured as per the set industry standards, our Unmonitored Spray Nozzle is high in demand in the market. It can be obtained from us at a very reasonable price. Uses : Cement Mill, Raw Mill, Ball Mill and Kilns

Type : Spray Nozzles

Diameter : 0.5-1mm, 1-2mm, 2-4mm, 4-6mm

Application : For Spray

Application : Industrial Use

Color : Black

Finishing : Polished

Pressure : High, Low, Medium

Feature : Fine Finished, Heat Resistance, Highly Durable, Light Weight

...more

Two Line Dose Feeder

We are an experienced name, which is engaged in manufacturing and supplying Two Line Dose Feeder. The outlets of our Two Line Dose Feeder are connected parallel. Moreover, the outlet ports are connected to lubrication points by means of tubing. The functioning of entire equipment can be noticed by the movement of indicating pin. We make available Model TLDF 2, 4, 6, 8 and 10 Outlet with respect to output in CC like 2.3 & 5 CC/outlet/cycle.

Type : Dose Feeders

Certification : CE Certified

Application : Batching, Dosing, Mixing

Weight : 10-100kg

Color : Shiny Silver

Voltage : 220V

Capacity : 100kg/hr, 200kg/hr

Frequency : 50Hz, 60Hz

Automatic Grade : Semi Automatic

Power : 0-5kw, 10-15kw, 15-20kw

Driven Type : Electric

Warranty : 1yrs

...more

Spray Nozzles

We are credible Manufacturers and Suppliers of Spray Nozzles in Pune, Maharashtra. We use high-grade metal and other raw materials in order to provide strong and durable Nozzles. Our Spray Nozzles are fabricated as per the industry standards in order to provide efficiency and high-performance. Our Spray Nozzles are available in different sizes to meet the requirement of different customers. Our Spray Nozzles are easy to install and available at competitive prices. Features : Lightweight Easy to install Long functional life

Type : Spray Nozzles

Diameter : 0.5-1mm, 1-2mm, 2-4mm, 4-6mm

Application : For Spray

Application : Industrial Use

Color : Golden

Finishing : Polished

Pressure : High, Low, Medium

Feature : Heat Resistance, Highly Durable, Light Weight, Non Breakable, Rustproof

...more

Single Line Progressive Type Lubrication System

Single Line Progressive Type Lubrication System that we offer is manufactured using the latest techniques under the guidance of experts. It is subjected to stringent quality tests so as to ensure its defect-free working. We are one of the eminent Manufacturers and Suppliers of Lubrication System. One can obtain Lubrication System from us in small as well as bulk quantities at the most reasonable prices. Principle of operation : Entire output of the pump is supplied to the bearing points through a distributor/metering device irrespective of varying pipe lines or bearing back pressures. Construction and Operation It consists of hydraulics/pneumatic/manual or motorized pump with a single line to the metering device and then to further metering devices or directly to the bearings. There is no return line hence this system can be TOTAL LOSS or can be RECIRCULATING type lubricating system. This system is very flexible with various types of pumps and progressive distributors up to 576 points. When a motor is started, pump delivers the lubricant under pressure to the distributor from where it is either deliverd to the next distributor in case of large number of points or directly to the bearings. Pecularity of this system is that, unless metered quantity of lubricant is delivered from one particular outlet of distributor, lubricant can’t be delivered from next outlet. This sequential operation makes the system SELF MONITORING type. Thus monitoring of a single outlet is as good as monitoring whole system. ApplicationPresses, Packing Machines, SPMs, Textile Machies, Crushers, Construction Machines and Plastic Processing Machines.

Type : Lubrication System

Certification : CE Certified

Application : Filling Tubes

Weight : 100-500kg

Voltage : 230V

Power : 1-3kw, 12-15kw, 3-6kw, 6-9kw

Driven Type : Electric

Warranty : 1year

Automation Grade : Fully Automatic, Semi Automatic

...more

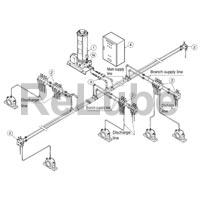

Single Line Injector Type Lubrication System

Single Line Injector Type Lubrication System that we offer is manufactured under the guidance of experts by following the set industry standards. We conduct stringent quality tests on Lubrication System so as to ensure that only the defect-free product reaches the customers’ end. We are listed among the top Manufacturers and Suppliers of Lubrication System. Buyers prefer to buy Lubrication System from us as we make it available at a very reasonable price. Principle of operation : Single main line runs from the pump to the farthest metering valve or injector directly or in branches. Construction of operationLubricant output from pump reaches each metering valve or injector directly from main line. Pressure and flow from pump forces spring loaded pump in the valve to move, dispensing metered quantity of lubricant from measuring chamber to bearings. After all the injectors are operated, further increase in pressure stalls pump and pressure switch it provided sends signal. Then venting cycle starts by reliving the pressurised main branch line and thus makes all the injectors ready for next cycle. ApplicationsGlass forming machines, Tyre tube curing presses, Hydraulic Presses, Food processing & Packaging machines, Textile machies and Earthmoving equipments.

Type : Centralised Lubrication Systems

Certification : CE Certified

Application : Filling Tubes

Weight : 100-500kg

Voltage : 230V

Rated Power : 1-3kw, 12-15kw, 3-6kw, 6-9kw

Driven Type : Electric, Hydraulic, Mechanical

Warranty : 1year

Automation Grade : Semi Automatic

...more

Progressive Distributor

Our company is an eminent name, which is counted among the top Manufacturers and Suppliers of Progressive Distributor. One can use it as primary as well as secondary distributor. The input quantity of lubricant is divided as per the outlet ports combinations in Progressive Distributor. The best thing about this distributor is that it works on progressive principle according to which, no lubricant goes to next outlet unless metered quantity of lubricant is delivered from previous outlet. We make available Progressive Distributor in Model 2, 4, 6, 8, 10 & 12 outlets with respect to output in CC from 0.2 CC to 0.5 CC/outlet/cycle. All the models of Progressive Distributor are equipped with an indicator pin which moves to and fro in one cycle.

Material : Metal

Type : Distributor

Finishing : Polished

...more

Oil Circulation System

Oil Circulation System that we offer comes with all necessary instruments that are installed at appropriate location for proper measuring of pressure, temperature, level and flow related data. Enough redundancy is built inside the system so that it requires less maintenance. It is perfect for dusty areas as the system is fully enclosed. We can customize Oil Circulation System as per the requirements specified by the buyers.Flow Range : 0.5 LPM to 500 LPM

Type : Oil Circulating System

Certification : CE Certified

Weight : 100-1000kg

Color : Multi Colour

Voltage : 110V, 220V

Power : 1-3kw, 3-6kw, 6-9kw

Warranty : 1year

Driven : Electric

Automation Grade : Semi Automatic

...more

Multi-Line Lubrication System

Multi-line Lubrication System that we offer consists of multi-outlet pump in which each outlet connected to individual bearing. When multi-outlet pump with progressive distributor, it offers system extension/flexibility to a great extent. Pump outlets are adjustable. A check valve is fitted inside each outlet that ensures positive dispensing. We are counted among the top Manufacturers and Suppliers of Multi-line Lubrication System. It can be obtained from us at the best market price. Application : Medium and large size Presses, Earthmoving Equipments, Screw Conveyers, Punching Presses, Mixing Mills, Crushers, and Turbines etc.

Type : Lubrication System

Certification : CE Certified

Application : Filling Tubes

Weight : 100-500kg

Voltage : 230V, 440V

Rated Power : 1-3kw, 12-15kw, 3-6kw

Driven Type : Electric

Warranty : 1year

Automation Grade : Semi Automatic

...more

Monitored Spray Nozzle

Self-monitored Spray Nozzle is available with us. It is monitored by limit or proximity switch. We are counted among the top Manufacturers and Suppliers of Monitored Spray Nozzle. It is operated by progressive dosing of lubricant. Monitored Spray Nozzle cannot operate unless both air and lubricant are available. Moreover, it always operates at right pressure. It finds extensive usage in large open gear drives of cement mill, raw mill, ball mill and kilns.

Type : Spray Nozzles

Diameter : 0.5-1mm, 1-2mm, 2-4mm, 4-6mm

Application : For Spray

Application : Industrial Use

Color : Silver

Finishing : Polished

Pressure : High, Low, Medium

Feature : Fine Finished, Heat Resistance, Highly Durable, Light Weight

...more

Hydraulically Operated Direction Control Valve

We make available Hydraulically Operated Direction Control Valve in different models with flow rate 6000 & 14000 CC/hour. Change over pressure is set at approx. 40 bars, which is higher than actual system operating pressure. It comes with adjustable change over pressure 350 bar Max and 80 bar Min. It finds extensive usage in dual line centralized lubrication system. Hydraulically Operated Direction Control Valve can be monitored by indicator pin that provides signal after each cycle to start and stop the pump.

Material : Carbon Steeel, Metal, Stainless Steel

Color : Silver

Automatic Grade : Automatic, Manual

...more

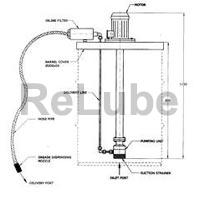

High Pressure Motorised Grease Pump

High Pressure Motorised Grease Pump can be used as a central lubrication pump for oil or grease lubrication. It is used with single line progressive as well as dual line system. We are enlisted among the reputed Manufacturers and Suppliers of Motorized Pump. It can be provided with unit of filter, pressure gauge, safety valve and excess pressure switch or without the unit. Additional two ports are provided with our Motorized Pump, one for refilling oil or grease and other for return line connection which is required in case of dual line system. Technical Specification No. of Outlets upto 2 Max Delivery Pressure 450 bar Output/hour - 6000 CC, 8000 CC, 10000 CC, 14000 CC, 18000 CC Reservior capacity – 30/60/100 Ltrs Drive Motorized with worm gear reduction assembly or with helical gear reduction box Lubricant any oil & grease upto NLGI 2 Optional Features Pressure Relief Valve, Pressure Guage, Low Level Switch, Pressure Plate with tell tale rod or Stirr Assembly, Excess Pressure Switch assembly. Accessories Electrical Control Panel for Automatic operation High Pressure Hydraulic Fittings and Seamless Pipes

Type : High Pressure Pumps

Application : Agrictulture, Automotive, Industrial, Marine

Weight : 10-20kg, 20-300kg

Color : Green

Voltage : 220V

Power : 10hp, 1hp, 2hp, 3hp

Driven Type : Electric

Pressure : High Pressure

Warranty : 1year

Certifications : CE Certified

...more

High Pressure Multioutlet Grease Pump

High Pressure Multioutlet Grease Pump that we offer comes with individual output adjustment. This pump can be used for covering lubrication points. We are named among the renowned Manufacturers and Suppliers of Grease Pump. The manufacturing of our Grease Pump is done using highly advanced techniques under the strict vigilance of experts. One can obtain the Grease Pump from us at a very reasonable price. Technical Specifications No. of Outlets upto 30 Max Delivery Pressure 350 bar Adjustable discharge 0.05 CC – 0.25 CC/Stroke/Outlet Reservior capacity – 5/10/15/30 Ltrs Drive Motorized with worm gear reduction assembly Lubricant any oil & grease upto NLGI 2 Optional features : Pressure Relief Valve, Pressure Guage, Low Level Switch, PressurePlate with tell tale rod. AccessoriesControl panel for intermittent operation High Pressure Hydraulic Fittings and Seamless Pipes ApplicationsMedium and Large size Presses, Earthmoving Equipments, Screw Conveyers, Punching Presses, Mixing Mills, Crushers, and Turbines etc.

Type : High Pressure Pumps

Material : Polypropylene

Application : Agrictulture, Automotive, Industrial

Weight : 10-20kg

Color : Black

Voltage : 110V, 220V

Power : 10hp, 1hp, 2hp, 5hp

Driven Type : Electric

Pressure : High Pressure

Warranty : 1year, 2years, 5years

Certifications : CE Certified

...more

Grease Spray System

We are named among the renowned Manufacturers and Suppliers of Grease Spray System. In this system, special lubricant is pumped with the help of motorized or pneumatic pump which is then, supplied to progressive metering device through unit of filter and safety valve. Our Grease Spray System is well tested and thus, buying it from us will be the safest option for the buyers. Mainly two types of spray nozzles are used in this system : Monitored : It is monitored by Limit or Proximity switch. It can be operated by progressive dosing of lubricant. The nozzle doesn’t operate unless air and lubricant both are available and at right pressure. Unmonitored : In this system lubricant is monitored through limit switch and air is monitored through pressure switch installed after the last nozzle. In this nozzle, spray of specific size is achieved by spraying after mixing of Air & Lubricant. Application : Open Gear Drives of Cement Mill, Raw Mill, Coal Mill & Kilns & Chain Conveyers.

Type : Spray Machine

Certification : CE Certified

Color : Multi Colour

Voltage : 220V, 380V

Power : 1-3kw, 3-6kw, 6-9kw, 9-12kw

Driven Type : Pneumatic, Electric

Warranty : 1year

Automatic Type : Manual

...more

Electrically Operated Direction Control Valve

Electrically Operated Direction Control Valve finds extensive usage in dual line centralized lubrication system. It changes over pressure line and return line alternatively after completing one half cycle. Our Electrically Operated Direction Control Valve comes with a maximum flow rate of 21000 CC/hour and maximum operating pressure 400 kg/cm2. It comprises of 24 VDC motor, eccentric cam, bearing, C bracket with plunger etc.

Size : 1.1/2inch, 1.1/4inch, 1/2inch, 1inch, 2inch, 3/4inch

Type : Electrically Operated Valves

Material : Brass, Carbon Steeel, Metal, PP, PVC

Application : Electrically Use

Pattern : Plain

Automatic Grade : Automatic

Pressure : Low Pressure, Medium Pressure

Feature : Blow-Out-Proof, Casting Approved, Durable

Temperature Of Media : Normal Temperature

Number Of Way : 2way, 3way

...more

Dual Line Lubrication System

Dual Line Lubrication System that we offer is well tested and therefore, is the perfect option on which buyers can easily rely. We are reckoned as one of the reputed Manufacturers and Suppliers of Dual Line Lubrication System. Manufactured under the strict vigilance of experts, our Lubrication System is known for its longer functional life. Tested using the latest techniques, our Lubrication System is free from all kinds of defects. Principle of operation : Two parallel lines run from pump to control valves and from control valves to metering devices and then to bearing points. End of line pressure switch gives signal to change over the line and thus continuous operation is ensured. Construction & operationA single outlet pump, 4/2 way direction control valve, metering devices, end of line pressure switches etc. are important parts of the system. In this system, lubricant is supplied from central pump to control valve, which further supplies it to the main lines and ultimately to bearings. When pump os started, one of the main line gets charged, it delivers required quantity of lubricant to bearings and at that time other main line acts as a relief line. When end if line pressure switch sends signal to changeover the line (i.e. half of the total number of lubrication points are covered.) After getting signal from end of line pressure switch, the changeover valve operates and the other main line gets charged and remaining half number of lubrication points gets lubricated. This ensures one complete cycle. Advantages of this system is that the pump used is high volume, high pressure type and number of bearings can be centralised is large (up to 1000 points). Applications Sugarcane Crushing Mills, Steel Rolling Mills, Metal Processing Machines, Power Plant Conveyers and Grate Coolers.

Type : Dual Line

Certification : CE Certified

Application : Filling Tubes

Weight : 100-500kg, 1000-1500kg

Voltage : 230V

Rated Power : 1-3kw, 12-15kw, 6-9kw

Driven Type : Electric, Hydraulic, Mechanical

Warranty : 1year

Automation Grade : Semi Automatic

...more

Barrel Mounted Motorized Grease Transfer Pump

Barrel Mounted Motorized Grease Transfer Pump that we offer comes with drum cover, SS filter gauge, pressure relief valve and pressure gauge (0-350kg/cm2). It is suitable for 180 kgs standard grease barrel. We are counted among the top Manufacturers and Suppliers of Motorized Grease Transfer Pump. The manufacturing of our Motorized Grease Transfer Pump is done using the latest techniques under the strict vigilance of experts.

...more

Industrial Valves

injectors

Manifold Valve

Spray Nozzle

orifice plate assemblies

Opening Hours