robotic welding system

2,000,000 Per Piece

1 Piece (MOQ)

Robotic Welding Systems (SPM).Our complete product range is manufactured under the supervision of trained personnel who use the utmost quality raw material.

Welding Robotic System

100,000 Per Piece

1 Piece (MOQ)

Best Deals from Robotic System

Robotic Cell Entire Protection System

Get Price Quote

Provides Complete Robotic protectionwith Machine safety curtains. Safety Relay. Interlock switches, LASER Scanner. Self-Checking Touch Buttons E-Stop Buttons

Robo Pouring System

5,000,000 - 8,000,000 Per Piece

1 Pound (MOQ)

SCARA Robots

Get Price Quote

Industrial robots play an important role in the development of automated production. To meet the high requirements for industrial robots, Delta's ASDAMS series robot controller is equipped with real-time performance, high flexibility and highly competitive motion controlcapabilities.The ASDA-MS series perfectly integrates robot controller, multiple servo drives, Delta's self-developed high-speed DMCNET communication network and general communication interfaces into one unit that provides high speed, and high precision and high performance. Delta's Programmable Automation Controller (PAC)MHI Series features the perfect integration of motioncontrol and logic programming control. It enablesbetter synchronization with EtherCAT and DMCNETcommunication and can connect to various slave modules and servo systems with either an EtherCAT or DMCNET network interface. These communication interfaces offer high response and high precision control for more flexible operation, and are ideal for high-performance multi-axis motion control. Robot Controller with Servo Drive Integrated ASDA –MS : Complete Robot Solution Integrated servo drive and controller in one single unit for real time motion control with high fl exibility and reliability. Supports various communication protocols Built-in with diverse robot control modules Up to 10 axes motion control: 4-axis robot + 6 external axes Supports IEC 61131-3 standard for fi ve kinds of programming languages and the PLCopen motion function block Offers DRL Languages for developing robot application programs Supports G-Code programming for path planning

Robotics Process & Integration Simulation

Get Price Quote

Robotics process & integration, simulation brings brilliant takeaways for manufacturing organizations. This digital manufacturing solution delivers you a virtual 3D environment to work and enable speedy works being completed within seconds. These integrated solutions are the need of the hour for every manufacturing organization and we, Shiv Technology work on giving you the top automated solutions for your smooth workings. Why are robotics, process & integration, simulation, a valuable tool? Considering a tool the most worthy for your business unit without knowing about its privileges is not as easy as it looks. But for you, we are bringing here the reasons of should you adopt it and how could it prove as valuable to your firm. Great production quality, faster launches, proper optimization, validation, and simplifying manufacturing processes make it the most valuable tool. It vouches for extreme safety while moving, carrying material or performing operations, enhanced efficiency and of course higher productivity. The operations abide by quality control techniques. The best part is, everything is carried on by adhering to the safety standards. So robotics process and integration simulation by Shiv Technology is completely safe to use and keep the hazardous outcomes at bay. Specifications Greater flexibility Exquisite quality Assured results Safe to use Applications Upfront virtual validation is possible leading to less physical prototypes Early detection of product related issues Reuse of standard facilities and tools, and hence, the cost reduced Ergonomically safe processes can be carried on Simulation of various manufacturing scenarios is possible and as its takeaway, the production risk gets reduced. Production commissioning validation is attainable Emulation of realistic processes which ultimately enhance process quality. With robotics process and integration simulation, you get a lot of benefits with the smooth manufacturing process. The flaws get automatically abated, which results in minimum wastages and increased outputs. We guarantee the quality and performance of this tool. We hope, now you get to know how is it helpful and more precisely, valuable to your unit? So, when are you resorting your manufacturing unit to robotics process and simulation integration? Contact us, share your requirements and resort to this flawless tool.

SCARA & Articulated Robots

Get Price Quote

All type of Eoat Robot gripper spares

8,000 - 22,000 Per Piece

10 Piece (MOQ)

We have manufacturer & supply of all type of Robotics Gripper Parts,we also manufacture as per customer requirements,light weight,durable,flexible,safer.spring mounted double blank detector quick change for cross bar Feeder,Hexa Feeder,Loader unloader

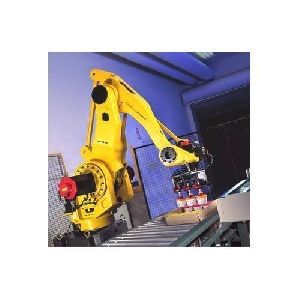

robotic system

Get Price Quote

We are deal with all type of robotics system integration like welding application, machine tending cell, Handling & Palletizing Cells, Integration & Programming Services,

cartesian robot

350,000 Per Piece

industrial robot

15,000 - 1,500,000 Per Piece

3 Piece(s) (MOQ)

We are in industrial robot manufacturing system. Industrial robots are automated, programmable and capable of movement on three or more axis. Typical applications of robots include welding, painting, assembly, pick and place for printed circuit boards, packaging and labeling, palletizing, product inspection, and testing; all accomplished with high endurance, speed, and precision. They can assist in material handling.

cartesian robot

400,000 Per Piece

1 Piece (MOQ)

Automation and Robotic Systems

Get Price Quote

Previous Next Automation of manufacturing and industrial processes, has today become the key word, in an era of fierce competition and fluctuating economies. This has invariably led to extensive deployment of robot configurations for typical industrial applications. Enhanced productivity, better and consistent quality, low operational/labor costs, precision, reduced risks and greater safety are the primary benefits achieved through automation. With a focused approach on delivering these vital benefits to our clients, Global Autocon takes pride in designing and engineering a wide range of robotic products and systems, which now form an integral component in the entire value stream and rule the future of manufacturing industries. We deliver robotic systems for various automotive and other manufacturing applications including welding, pick-and-place systems, gantry systems, assembly lines, paint-shops, packaging et al thereby providing a competitive edge to our clients. Global Autocon products target optimal performance and are certified by various safety standards to ensure seamless operation in the entire manufacturing process. Our products are also targeted to be highly efficient in energy saving, maintenance and different operating conditions. Global Autocon emphasizes on the basic fact that robotic systems can be effectively utilized to perform tedious, monotonous, and probable life-risking jobs. This overrules the traditional perception of robots replacing workers, and workers being rendered jobless. Interestingly Global Autocon always propagates the concept of enhancing labor skill-sets in various other functions requiring manual intelligence by letting robots take care of manufacturing activities which involve risk to human life.

Inspection Robot

5,000,000 Per Unit

cartesian robot

410,000 Per Piece

1 Set (MOQ)

robotic welding system

Get Price Quote

Samarthan Systems Pvt. Ltd. is an ISO 9001 and CE certified company working in the field of Robotics integration, Process Automation and Manufacturing of Special Purpose Machining, Conveyors, Industrial washing machine, Leakage Testing Machine and Control Panels. We provide integrated end-to-end solutions which are oriented towards the success of our customers in product development, manufacturing, standardization and maintenance. We are Authorized Distributor to TAL Robots. We sale, support and implement their as well as NACHI, ABB, Motoman and Fanuc's solutions.

Robotic Automation System

600,000 Per Unit

1 Unit (MOQ)

Driven Robot

Get Price Quote

Material Handling Robotic System

1,200,000 Per Unit

1 Unit (MOQ)

Axis Robot Trainer

Get Price Quote

This trainer is designed for students to get familiarize with real life to factory automation system. Metal case can be unscrewed to view internal parts in working condition. The kit consists of Electro Mechanical system.