Rockwell Hardness Tester

Get Price Quote

1 Piece (MOQ)

Rockwell, Rockwell cum Brinell, Rockwell cum Rockwell Superficial We have Rockwell , Rockwell Cum Rockwell superficial and Rockwell Cum Brinell Hardness Teseter in Analogue and digital version. These models strictly conforms to IS: 1586-2000, BS: 891 part 1 & 2 for Rockwell & Rockwell superficial test. IS: 2281-1983, ASTM-E-10 for Brinell Test. Hardness Testers are designed and developed after years of experience in this field. All the models are manufactured under strict quality control at all manufacturing stages. These models are suitable for testing hardness of metals and alloys of all kinds, hard or soft, whether flat or round etc. or of irregular shape. These testers are simple in design and easy to operate, still yet quite sensitive and accurate. These models strictly conforms to IS: 1586-2000, BS: 891 part 1 & 2 for Rockwell & Rockwell superficial test. IS: 2281-1983, ASTM-E-10 for brinell test. Rockwell System Automatic weight selection with automatic zero setting dial gauge. Automatic weight selection with automatic zero setting dial gauge with more testing height and throat Rockwell cum Brinell Combined System Automatic weight selection with automatic zero setting dial gauge. Arrangement similar to RS with two additional weights of 185.5 kgf and 250 kgf for brinell tests. On this machinesmall pin having Dia 2 mm can be tested as plunger is guided with a set of six bearings. Rockwell cum Rockwell Superficial Combined This hardness tester is similar above machine in construction, and with automatic weight selection. This is useful for carrying Rockwell and Rockwell Superficial tests. The Rockwell Superficial method is useful for checking hardness of very thin sheets and surface hardness. Motorized Hardness Tester models are also available in the above models. Application and removal of major load is motorized. Motorized models have semi automatic operations for products testing. Drive motor-single phase, 230-V, 50 cycles AC.

Digital Rockwell Hardness Tester

Get Price Quote

Digital Hardness Tester for Rockwell Tests has motorized automatic cycle operation, i.e.. load/dwell/unload. The Preliminary Test Force is 98.07N (10kgf). Total Test Force is 588.4, 980.7, 1471N (60,100,150 kgf). Test Force Selection is by external mechanical dial. The system has bar indication on display for Preload. User can set Preload Dwell time, Dwell time for Total Load and Elastic recovery Dwell. The operation is easy with keyboard entry through reliable membrane switches for scale/HI-GO-LO/Dwell time selection. The scale display is with 0.1 Rockwell Resolution. The system has real time measurement and indication with Digital Dial Indicator of 1 micron resolution. The machine has feature of data export to PC or serial printer. It gives results indicating serial, number of tests, hardness scale, hardness value and high / good / low indication w.r.t limits entered. The Digital Rockwell Hardness Tester (VMCRASNE) covers Rockwell scale A, B, C, D, E, F, G, H, K, L, M, P, R, S, V and confirms IS : 1586, BS EN ISO 6508-1:2005 & ASTM E-18. The Digital Rockwell Superficial Hardness Tester (VMCRSNE) includes all Rockwell scales and 15T, 30T, 45T, 15N, 30N, 45N, 15W, 30W, 45W, 15X, 30X, 45X, 15Y, 30Y, 45Y and confirms IS : 1586, BS EN ISO 6508-1:2005& ASTM E-18. Options Available External serial thermal printer to print reports PC software : To interface machine in PC Export mode

Best Deals from Rockwell Hardness Tester

Rockwell Hardness Tester

Get Price Quote

Pg Corporation is counted amidst the renowned Manufacturers and Suppliers of Rockwell Hardness Tester. Designed and developed by our skilled engineers after years of research, the Rockwell Hardness Tester is the perfect equipment for testing the hardness of all kinds of metals and alloys, whether hard, soft, flat or round. The Rockwell Hardness Tester offered by us is known for its sturdy make, hassle free performance, easy usage and high efficiency. Further, we make available this Rockwell Hardness Tester to the clients in varied specifications at the industry leading prices. Technical Specifications : Loads : 60, 100, 150Initial Load : 10 kgMaximum Test Height : 230mmDepth of throat : 133mmMaximum Depth of elevating Screw below base : 240mmSize of base : 171x423mm (approx.)Machine Height : 635 mmNet Weight : 75 kg

TOUCHSCREEN ROCKWELL HARDNESS TESTER

Get Price Quote

TOUCHSCREEN ROCKWELL HARDNESS TESTER - FULLY AUTOMATIC Model - RASNE - TS FA 4.3" Touchscreen display. Suitable for Rockwell tests. Fully Automatic Motorized operation. Auto zero setting dial gauge. Motorized loading-unloading system. Built-in Hardness converter. Auto load & scale selection.

. Rockwell Cum Brinell Hardness Tester

Get Price Quote

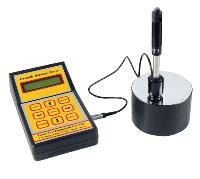

The Rockwell Brinell scale is a hardness scale based on the indentation hardness of a material. The Rockwell Brinell test determines the hardness by measuring the depth of penetration of an indenter under a large load compared to the penetration made by a preload. There are different scales, which are denoted by a single letter, that use different loads or indenters. The result, which is a dimensionless number, is noted by HRX where X is the scale letter. When testing metals, indentation hardness correlates linearly with tensile strength. This important relation permits economically important nondestructive testing of bulk metal deliveries with lightweight, even portable equipment, such as hand-held Rockwell Brinell hardness testers.

Rockwell Hardness Testers

Get Price Quote

The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test determines the hardness by measuring the depth of penetration of an indenter under a large load compared to the penetration made by a preload.[1] There are different scales, denoted by a single letter, that use different loads or indenters. The result is a dimensionless number noted as HRA, HRB, HRC, etc.,

Digital Rockwell Hardness Tester

Get Price Quote

We are offering digital rockwell hardness tester. Digital hardness tester for rockwell tests has motorized automatic cycle operation i.e. Load/dwell/unload. The preliminary test force is 98.07n (10kgf). Total test force is 588.4, 980.7, 1471n (60,100,150 kgf). Test force selection is by external mechanical dial. The system has bar indication on display for preload. User can set preload dwell time, dwell time for total load and elastic recovery dwell. The operation is easy with keyboard entry through reliable membrane switches for scale/hi-go-lo/dwell time selection. The scale display is with 0.1 rockwell resolution. details the system has real time measurement and indication with digital dial indicator of 1 micron resolutionthe machine has feature of data export to pc or serial printer. It gives results indicating serial number of tests, hardness scale, hardness value and high / good / low indication w.r.t limits entered. The digital rockwell hardness tester (vmcrasne) covers rockwell scale a, b, c, d, e, f, g, h, k, l, m, p, r, s, v and confirms is : 3804, bs 10109-2 & astm e-18. The digital rockwell superficial hardness tester (vmcrasne/s) includes all rockwell scales and 15t, 30t, 45t, 15n, 30n, 45n, 15w, 30w, 45w, 15x, 30x, 45x, 15y, 30y, 45y and confirms is : 5073, bs 10189-2 & astm e-18 options available external serial thermal printer to print reportspc software – to interface machine in pc export mode

Rockwell Hardness Testers

Get Price Quote

Features : Rockwell, Rockwell Brinell Combined, Rockwell / Rockwell Superficial Combined System Hardness Testers. Hardness Testers, Model RAS, RAB-1, RAB-250, TWIN are manually operated. All these models are suitable for testing hardness of metals sand alloys of all kinds hard or soft, whether flat, round, or irregular shape. These testers are simple in design and easy to operate, yet sensitive & accurate. Various models from the wide range are suitable for schools, laboratories, tool-rooms, inspection, heat treatment departments, factories etc.These testers strictly confirms to IS : 1586 - 2000, ASTM : E 18 for Rockwell Superficial Test and IS : 2281 - 2005, ASTM : E 10 for Brinell test.

Rockwell Cum Brinell Hardness Tester

Get Price Quote

Salient Features Motorized system for application and removal of major load Minor load setting by LED bar graph Keyboard entry for scale selection Hi-Low-OK indication for hardness value Easy to read, large size extra bright 7 segment display Centronics parallel port for connecting Dot Matrix Pinter Sufficient error codes for smooth functioning of machines Serial interface (Optional) Least Count 01 for Rockwell and 0.2 for Rockwell Superficial Dwell Time 1 to 99 Seconds . Scale Displayed A,B,C,D,E,F,G,H,K,L,M,N,P,R,S,V in Nos. 1 to 15 Resp. and 15N,30N,45N,15 T,30T,45T in Nos. 1 to 21 Resp. for Superficial Indenter is guided in linear bearing facilitates to test small jobs

Rockwell Hardness Tester

Get Price Quote

Rockwell Hardness Tester, hardness testing machines, Brinell Hardness Tester