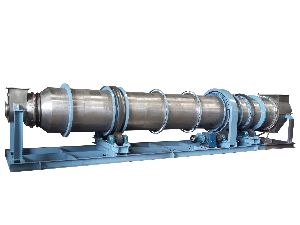

Rotary Dryer

Get Price Quote

Rotary Dryers / Coolers are widely used in the Industry for drying / cooling of reasonably free flowing materials. AVM offers Customized Rotary Drying Systems with variety of Configurations. DIRECT ROTARY DRYERS & COOLER The material to be dried / cooled comes in direct contact with the drying / cooling media. The dryer comprises of a rotating shell supported on rollers / tyres and driven by means of suitable drive arrangement. Drying / Cooling media (Air / Gas) is admitted through stationary hood at one end & taken out from stationary hood from other end. Feed is admitted through suitable feeding mechanism like Screw feeder / Chute. The rotating shell is provided with specially designed material showering mechanism like Lifters / Garland Chains etc. Shell inclination & rotating speed facilitate forward movement of the material towards discharge end providing required residence time. Drying (or Cooling) takes place by heat transfer to (or from) showering material with the drying (or Cooling) media within the shell. Product is discharged from the stationary hood through suitable equipment like Flap Valve / Rotary Valve / Screw Conveyor / Chute. Air Flow Configurations : Co-Current Flow Counter-Current Flow Air Heating System Configurations : Direct Fired / Indirect Fired Air Heaters: using Liquid / Gaseous Fuels. Direct / Indirect Fired Air Heaters: using Solid Fuels, Agro Waste, Saw Dust, Rice Husk, Coal, Briquette etc. Indirect Air Heaters: Using Steam / Hot Oil / Thermic Fluid. Electric Air Heaters: using electricity. Product / Fines Recovery System Configurations : Cyclone Separators: Mono, Twin, Quadruple, Multi etc. Bag Filters: Reverse Pulsejet, Mechanical shaking etc. Wet Scrubbers – Direct Contact Ventury, Adjustable Ventury, Packed scrubbers etc. Optional Features Configurations : Feed material conditioning. Back mixing of product with feed material. Pneumatic conveying system and finish product handling. Computerized control system through PLC / DCS & SCADA. IN-DIRECT ROTARY DRYERS The material to be dried does not come in direct contact with the drying media. The dryer comprises of an assembly of two concentric rotating shells supported on rollers / tyres and driven by means of suitable drive arrangement. Feed is admitted through suitable feeding mechanism like Screw feeder / Flap Valve into the dryer through stationary feed hood. The drying media is admitted through the inner shell & travel towards discharge end & again returns towards feed end through specially designed return gas passages on the inside of outer shell. The inner shell is also provided with suitable radial lifters. These lifters along with return passages geometry is designed for showering of feed material. Shell inclination & rotating speed facilitate forward movement of the material towards discharge end providing required residence time. Drying takes place by heat transfer to the showering material by direct contact with inner shell & return passages. Product is discharged from the stationary hood through suitable equipment. Air Heating System Configurations Direct Fired Air Heaters : Using Liquid / Gaseous Fuels. Direct Fired Air Heaters : Using Solid Fuels, Agro Waste, Saw Dust, Rice Husk, Coal, Briquette etc. Product / Fines Recovery System Configurations : Cyclone Separators: Mono, Twin, Quadruple, Multi etc. Bag Filters: Reverse Pulsejet, Mechanical shaking etc. Wet Scrubbers – Direct Contact Ventury, Adjustable Ventury, Packed scrubbers etc. Optional Features Configurations : Feed material conditioning. Back-mixing of product with feed material. Pneumatic conveying system and finish product handling. Computerized control system through PLC / DCS & SCADA.

Rotary Vacuum Dryer

300,000 Per Piece

1 Piece (MOQ)

Best Deals from Rotary Dryers

rotary cone vacuum dryer

Get Price Quote

We offer secured online and offline payment processing methods. The transaction, done through online mode, is instantly forwarded to the payment system. We also accept bank account transfers, cash payments, etc. We have a team of qualified personnel to ensure proper quality control of products is done so that products are as per buyer's quality requirements. Features: High-performance Robust construction Easy operations & maintenance

Rotary Vacuum Paddle Dryer

Get Price Quote

1 Piece (MOQ)

Colour Speckles Rotary Dryer

Get Price Quote

Rotary dryer are used for to reduce or minimize the moisture content present in the feed. This feed material comes in direct contact with hot gas .This rotary dryer is made up of rotating cylinder and number of tubes fitted inside. OR only lifters are provided on Periphury. We manufacturer of Rotary Dryer for Colour Speckles, DDGS etc. The material which is to be dried enters into the dryer and since the dryer is rotating , the material is lifted up by series of internal fins lining the inner wall of the dryer. After getting high enough, the material falls down back to the bottom of the dryer , passing through the hot gas steam and thus the drying takes place . This dryer can be designed either with co-current OR counter current flow. Advantages : Simplicity in design. Sturdy construction. Adaptability to fluctuating feed rates and moisture contents of product Possibility of very large through puts. Can handle wide range of material . Can handle highest drying temperature.

Rotary Dryers

Get Price Quote

We make use of suitable packaging material to deliver the product safely and in the stipulated time span. We have most up-to-date machines and cutting-edge technologies to make sure that the products are packed accurately. This assures that the products are safe from the external damaging factors. Applications: Silica sand Bagasse Mineral processing Food processing industry Biochemical Pharmaceutical Technical Specifications : This Rotary dryer is made available in different capacity varying from 100kg/hr to 50000kg/hr product rate along with operating temperatures up to 600oC. Features: High thermal efficiency Helps in drying, cooling or calcination Design permits highest possible drying temperatures Efficient drying of materials with high moisture contents Handles a wide size range of materials with extended residence times

Rotary Dryers

125,000 Per Piece

1 Piece (MOQ)

Sand rotary dryer

1,500,000 Per Piece

cGMP Rotary Vacuum Paddle Dryer.

3,000,000 - 5,500,000 Per Nos

1 Set (MOQ)

for Active Pharma In-gradient (API) Drying. Latest features in Vacuum Drying Technology with touchscreen HMI. Cylindrical body with close paddle gap, low thermal inertia jacket, cantilever type heated shaft, light with view port, No dead zone discharge valve. capacity range 100 L to 2500 Ltr.

Rotary Dryers

Get Price Quote

Rotary Dryer: Rotary Dryer is a type of industrial dryer employed to reduce or minimize liquid moisture contains of the material by bringing it direct contact with a heated gas. dryer is made up by large rotating cylinder which is slopes slightly so that discharge end is lower than material feed end in order to convey material under gravity. materials to be dry enters the dryer and as the dryer rotate. the material Filted up by the series of internal fins lining the inner wall of the dryer. Capacity: Capacity Range- 100 kg to 20000 kghr Temperature: Temperature Range max-1100 degree C Applications: Industrial Effuents Sludge Ammonium Bicarbonate Biomass Sodiums Clorides

Rotary Dryer

Get Price Quote

Easy to operate, our Rotary Dryer is widely used for drying or cooling of free flowing materials. Rotary Dryer works on a simple principle of minimizing the moisture content by maintaining a direct contact with heated gas. Clients appreciate our Rotary Dryer for low maintenance and ease of operation features. We can handle bulk delivery of Rotary Dryer with least hassle.

ROTARY DRYER SYSTEM

Get Price Quote

The rotary dryer is one of the most common types of industrial dryer, it is a cylindrical shell usually constructed from steel plates, slightly inclined and is usually operated with a negative internal pressure to prevent dust escape. Large quantities of granular material up to particles of 10 mm or larger that are not too fragile or heat sensitive or cause any other solids handling problems are dried in rotary dryers.

Rotary Vacuum Dryer

Get Price Quote

The drying in a rotary vacuum dryer is a batch operation under vacuum. Drying time depends on material being dried, amount of solvent or water to be removed, desired final moisture content, Limpet temperature etc. The dryer is available in sizes ranging up to 5000 Liters and is usually fabricated in ss304 0r 316 grade of material depending upon the application.

Rotary Vacuum Dryer

Get Price Quote

Rotary vacuum dryers offer clean, simple and effective method of drying wet cake, powder and even slurry. Labor and energy costs are minimal compared to tray dryers and product losses during handling are also negligible. Additionally valuable organic solvents can be conveniently condensed and recovered. The drying in a rotary vacuum dryer is a batch operation under vacuum. It is possible to dry heat sensitive materials at well below boiling points of water and solvents. Drying time depends on material being dried, amount of solvent or water to be removed, desired final moisture content, permissible jacket temperature etc. The dryer is available in sizes ranging from 100 liters to 20,000 liters gross volume. The volume of wet material loaded into the dryer is usually restricted to 40-45% of gross volume.

Rotary Vacuum Dryer

775,000 Per Piece

Rotary Dryers

Get Price Quote

Rotary dryers are used for drying wet powders and cakes, which are easily breakable and dispersible. The rotary dryer consists of a rotating drum with angle lifting blades which lift the feed as the drum rotates and showers it in the stream of hot air flowing through the drum.

CO-CURRENT ROTARY DRYER

Get Price Quote

Total control over moisture content The Co-current type Rotary Dryer is ideal for the materials that has tendency to stick and has high moisture content. Here Air and feed are introduced from the same direction and material comes in contact of hot air at its highest temperature,which instantly evaporates surface moisture. The initial heat transfer rate is high, causing an immediate and considerable drop in gas temperature, which prevents overheating of the material and the dryer shell. The material which is in its final stage comes in contact of airgas at its lowest temperature thus enabling the easy control over the moisture.

Rotary Dryers

Get Price Quote

Rotary dryer are widely used for drying wet powder and cakes,which are eassily breakable and dispersible.A revolving drum and purposefully placed flights combine to elevate and shower product uniformy through the air steam. Thermostatically handled discharge air temperature gurantees accurate final moisture and great sensitivity to changing product conditions. Features p>Efficient Drying with high moisture contents. High temperature drying. Handled wide range of size material.

electric rotary dryer

Get Price Quote

Based in Maharashtra(India), we are listed amidst the most celebrated names offering a spectrum of products. Buyers can order our products in bulk, as we maintain year around availability. In addition, we have reliable transportation system to make timely delivery.

ROTARY DRYER SYSTEM

Get Price Quote

The rotary dryer is one of the most common types of industrial dryer, it is a cylindrical shell usually constructed from steel plates, slightly inclined and is usually operated with a negative internal pressure to prevent dust escape. Large quantities of granular material up to particles of 10 mm or larger that are not too fragile or heat sensitive or cause any other solids handling problems are dried in rotary dryers.Rotary dryer system manufacturers, Rotary dryer system manufacturers Solids introduced at the upper end through the feed hopper and screw feeder assembly, material start moving towards the lower or discharge end. Depending on the arrangement for the contact between the drying air and the solids, a dryer may be classified as direct or indirect, co-current or counter-current. Feed material lifting flights of various shapes is constructed inside the shell to shower the solids in order to ensure contact with the hot air. These flight configurations vary from spirals to straight flights depending upon the material to be dried.

Rotary Drum Dryer

500,000 Per unit

Rotary Dryers

2,500,000 Per Piece

Rotary Atomizer Type Spray Dryers

Get Price Quote

We offer rotary atomizer type spray dryers. Our wheel or disc rotating rotary disc atomization is used for atomizing the liquid feed at high speed.

Rotary Disc Dryer

Get Price Quote

Rotary Disc Dryer drying is a highly efficient drying method with possibility to have close control over the particle size, bulk density and moisture content of the dried powder. The spray drying process consists of atomisation of the liquid feed into fine droplets with the help of spray nozzles or rotating disc. These fine droplets are brought in contact with hot air in a suitably designed drying chamber.

Rotary Vacuum Dryer

Get Price Quote

We present Rotary Vacuum Dryer that is extensively used in various industries for varied purposes. This Rotary Vacuum Dryer is generally used for drying moisture from industrial materials. Our Rotary Vacuum Dryer is manufactured using high grade raw materials. These Rotary Vacuum Dryers are acknowledged in the market for their high performance and cost-effectiveness. In Rotary Vacuum Dryer, a vacuum of up to 700 mmHg can be applied. Features Sturdy constructionLong service lifeAbrasion resistantHeat resistantPrecise dimensions Working Wet feed is charged and then subjected to secondary heatingWhile heating, the wet feed is subjected to agitation due to action of paddle mixingThe operation is carried out in vacuumThe solvent is recovered by condensing the vapors produced during drying operation

Rotary Sugar Dryer

Get Price Quote

Rotary sugar dryer is a drying machine which is used to dry the wet sugar coming from batch type centrifugal machines through sugar hoppers. It is designed superbly and it feeds rotary sugar dryer by means of screw feeder in to the dryer by way of screw feeder, belt conveyor or other appropriate mechanism depending on feed properties. It is attached with hopper in which feed material is poured which further comes into screw feeder into the dryer with, belt conveyor or other suitable mechanism works as per feed properties. The rotation of drum lifts the flight to the portion of dryer and the material’s portion downs to the dryers’ portion. Material comes in touch with the hot air while it falls down. As per the feed property and the requirement of process the counter current or co current flow depends. Direct or indirect hot air generator is used to produce drying media. This rotary sugar dryer is designed with a rotating cylindrical shell with internal lifters and also fitted with two cast steel tyres and sprocket. Chain and sprocket which is coupled to sprocket helps for the rotation of shell. The final rotation of drums shall be 4-6 rpm.

Rotary Vacuum Paddle Dryers

Get Price Quote

Rotary Vacuum Paddle Dryers, Liquid Liquid Extractor

Rotary Drum Dryer

Get Price Quote

Rotary Drum Dryer, Pneumatic Conveyors, Site Fabrication Services

Rotary Dryers

Get Price Quote

Rotary Dryers, industrial process automation, Roaster Machines, Spray Dryers